Circulating lubrication type shock absorbing structure

A circulating lubrication and shock absorber technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as radial swing and shake, and achieve the effect of small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

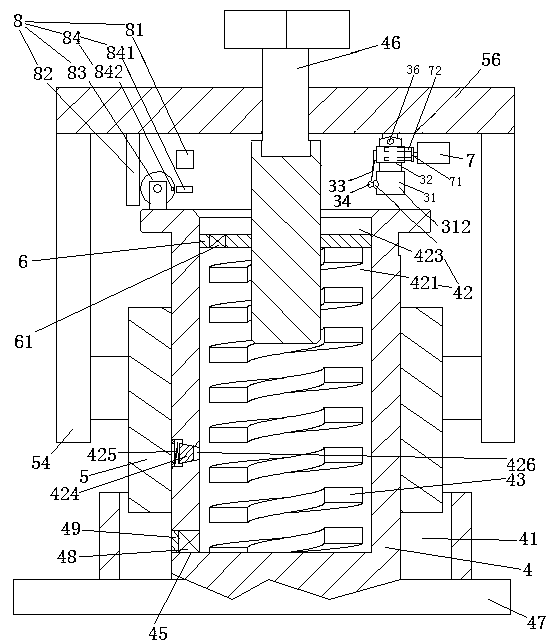

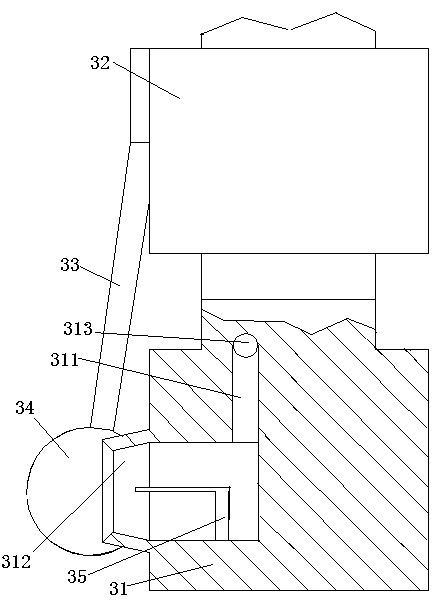

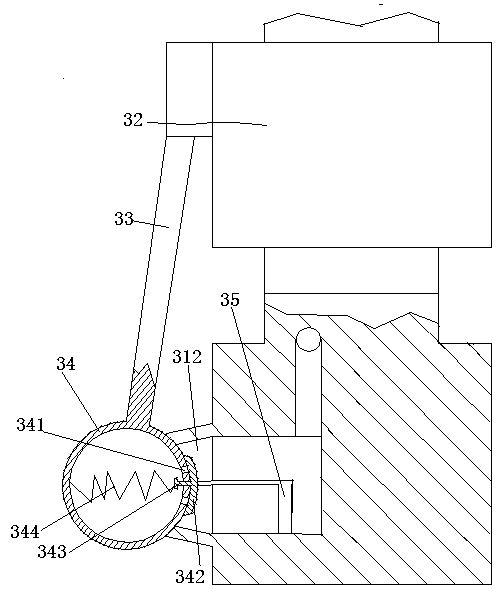

[0019] Embodiment one, see figure 1 , figure 2 , image 3 and Figure 4 , a circulating lubrication type shock absorber structure, including a connecting rod 4. A connecting cylinder 5 is sheathed on the connecting rod. The connecting rod is provided with an oil receiving groove 41 . The oil-saving groove is located under the connecting cylinder. The connecting cylinder is provided with two connecting plates 54 evenly distributed along the circumference of the connecting cylinder. The lower end of the connecting rod 4 is provided with a connecting seat 47 . When in use, one of the two objects that need to be connected together in a vibration-damping manner is connected with the connection base, and the other is connected with the connection sleeve. The upper end of the connecting bar is connected together with the cross bar 56. The cross bar is located above the connecting rod. The connecting rod 4 is a regular hexagonal prism structure, and the connecting rod and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com