Self-decompression type check valve

A technology of check valve and self-relieving pressure, which is applied in the direction of control valves, valve devices, and functional valve types, etc., can solve the problems of unadjustable pressure relief, uncontrollable pressure relief, and automatic pressure relief of check valves, etc., to achieve The opening pressure is adjustable, the pressure relief effect is controllable, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

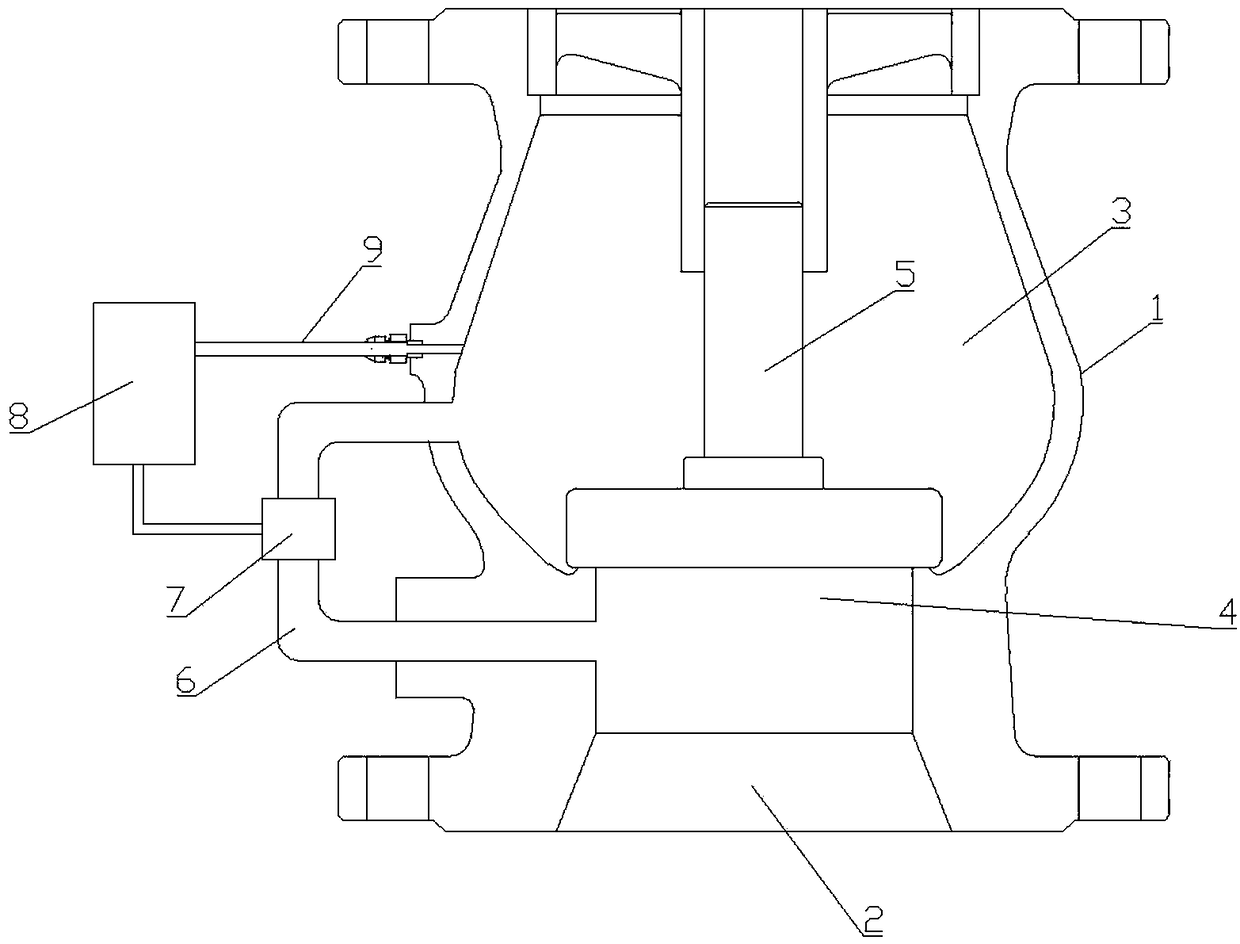

[0024] see figure 1 , this embodiment provides a self-pressure relief check valve, including a check valve body 1, a water inlet chamber 2, a water outlet chamber 3, and a first connecting chamber 2 and water outlet chamber 3 are arranged in the check valve body 1. A channel 4 and a non-return structure 5 for blocking and opening the first channel 4, and also includes a communication structure 6 connecting the water inlet chamber 2 and the water outlet chamber 3. The communication structure 6 only needs to be able to communicate with the water inlet chamber 2 and the water outlet chamber 3, it can be arranged on the outside of the check valve body 1 or can be opened on the check valve body 1;

[0025] The communication structure 6 is also equipped with a partition structure 7 that can block and open the medium to circulate in it. The partition structure 7 only needs to be able to achieve the purpose of partitioning the communication structure 6. The partition structure 7 can b...

Embodiment 2

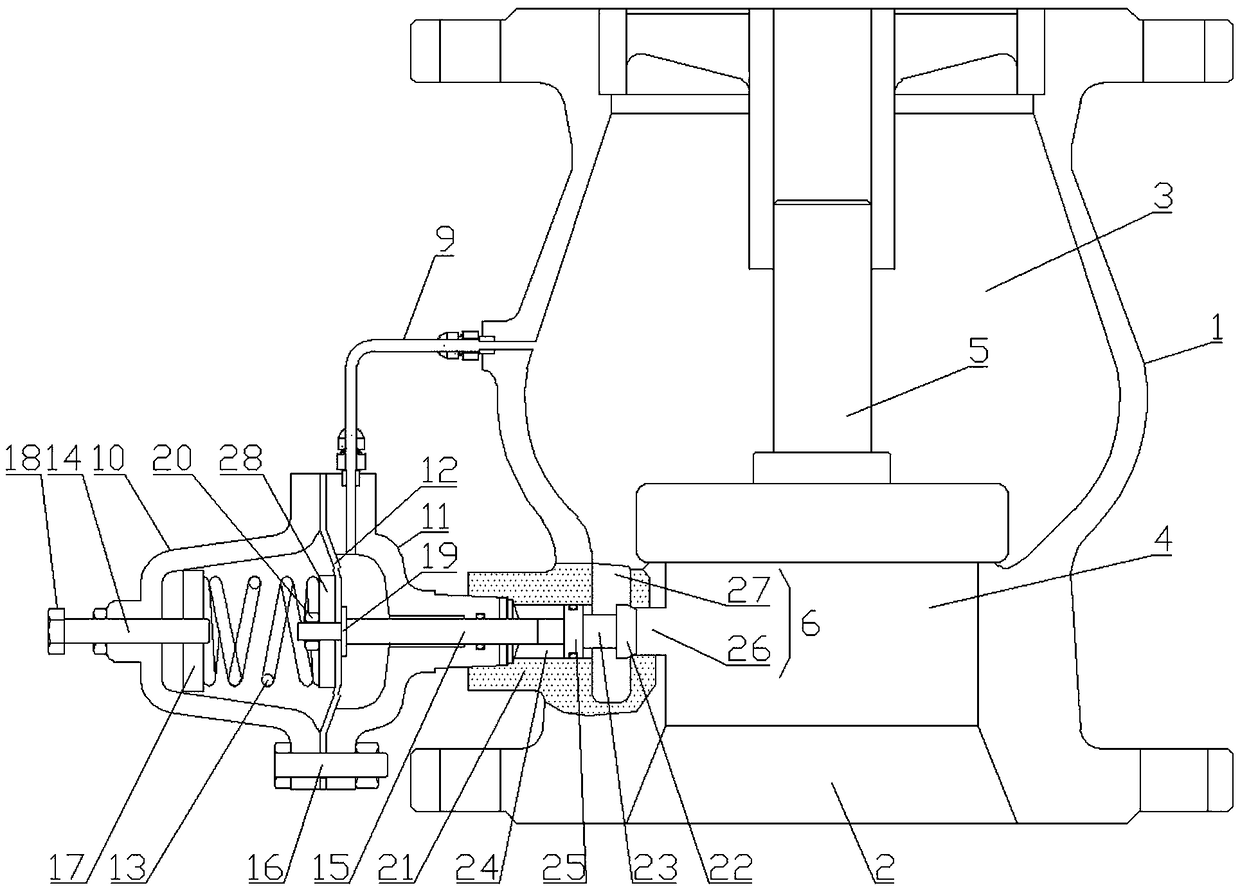

[0031] The manufacturing cost of the equipment in the first embodiment is relatively high. Therefore, in order to reduce the manufacturing cost of the equipment and realize the stable operation of the equipment (when the equipment contains electronic equipment, it is very easy to be damaged, and it is very easy to be affected by external power sources, etc.), therefore, this The embodiment is to improve the equipment.

[0032] In this embodiment, the adjusting device is specifically an adjusting shaft 14, and the adjustable pressure control structure 8 is specifically composed of a first housing 10, a second housing 11, an elastic diaphragm 12, a spring 13, an adjusting shaft 14, and an output shaft 15. Both the first housing 10 and the second housing 11 have a hollow cavity structure with one end open, and the opening end of the first housing 10 and the opening end of the second housing 11 are connected by bolts 16 to form an integral cavity structure, and An elastic diaphrag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com