Forming technology for rapidly growing into century-old tree through geometric weaving

A technology, fast technology, applied in application, cultivation, agriculture, etc., can solve problems such as long cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

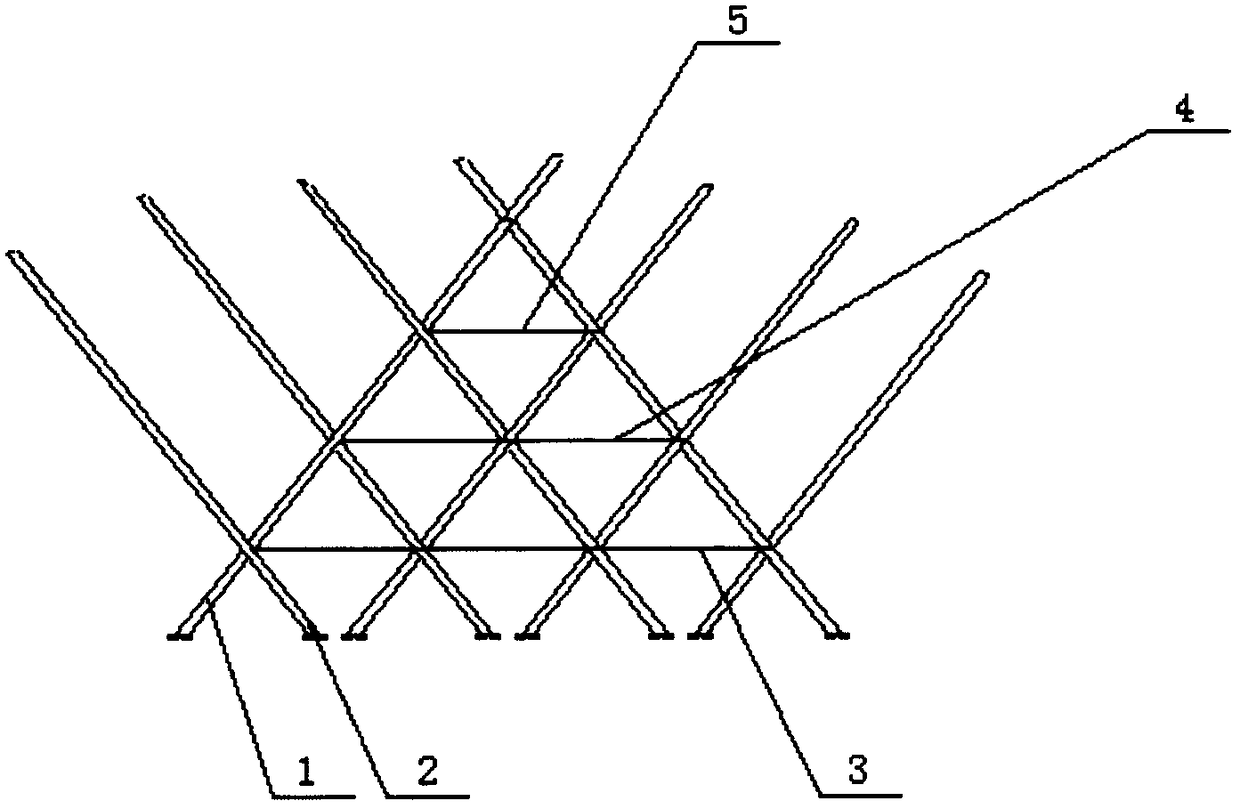

[0015] Such as figure 1 As shown, a geometric weaving rapidly grows into a century-old tree forming technology, which includes a weaving material and a weaving technology, and the weaving material is silk cotton wood, and the weaving technology is for each pair starting from a1, The first layer 3 intersects with the pair b2, using the inner side of a1 and the inner side of b2; the second layer adjacent to a pair of b2 intersects whether it is a1 or b2, it is the inner layer and the outer layer, and the cross is superimposed layer by layer. Fabrication distribution, layer by layer, inside and outside, all the way to the top; the acute angle between a1 and b2 ranges from 50° to 70°.

[0016] When adopting among the arbor trees with a dry height of more than 3.3 meters and a large arbor tree with a thickness of 1.5-2.5 centimeters to make weaving materials, the selection is silk cotton wood with high flexibility and survival rate. The tree is made up with 8 pairs (8X2 strains = ...

Embodiment 2

[0018] Such as figure 1 As shown, a geometric weaving rapidly grows into a century-old tree forming technology, which includes a weaving material and a weaving technology, and the weaving material is silk cotton wood, and the weaving technology is for each pair starting from a1, The first layer 3 intersects with the pair b2, using the inner side of a1 and the inner side of b2; the second layer adjacent to a pair of b2 intersects whether it is a1 or b2, it is the inner layer and the outer layer, and the cross is superimposed layer by layer. Fabrication distribution, layer by layer, inside and outside, all the way to the top; the acute angle between the a1 and b2 ranges from 50° to 70°, and the a1 and b2 are in a state of mutual contact at the root. Said a1 is parallel to a1, and b2 is parallel to b2. When the trunk height exceeds 3.3 meters and the thickness is 1.5-2.5 centimeters among the arbors, silk cotton wood with high flexibility and survival rate is selected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com