Double output shaft type roller press

A roller press and double output shaft technology, applied in the field of roller presses, can solve the problems of low production efficiency, large space occupied by equipment, and high cost, so as to improve production efficiency, reduce equipment cost input, and reduce cost input Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with specific embodiments.

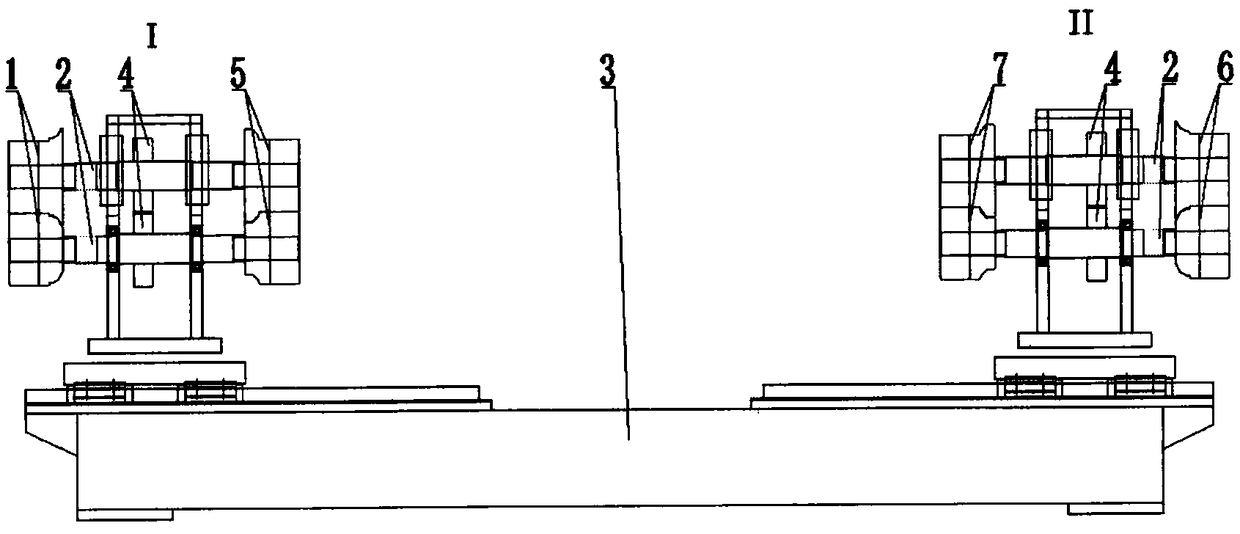

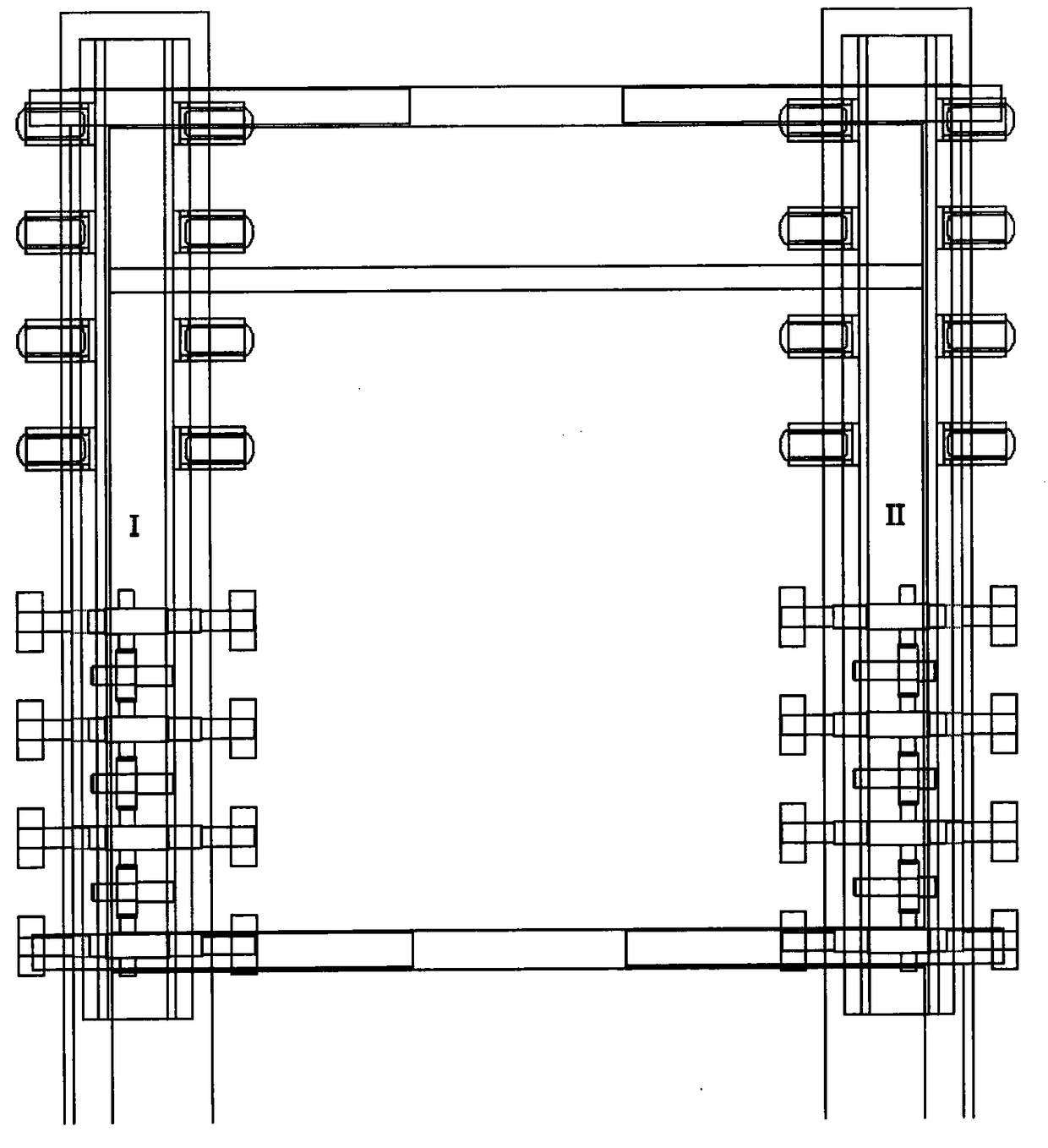

[0023] The invention changes the single wall panel structure of the ordinary roller press into a double wall panel box structure, and the double wall panel box structure can be integrally separated from the press base. Lengthen the roller shaft of the ordinary roller press, extend out the two sides of the double wallboard box structure, and leave the roller installation positions at both ends of the shaft. In this way, a roller installation position is formed on both sides of the box, and a set of rollers can be installed on both sides of a box structure. This means that the left and right sides of a box structure can be shaped into different color steel plates. When there are many types of panels, you only need to replace the double wall panel box structure. Through different combinations of different box structure wall panels, you can quickly combine new panel types, improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com