Self-lubricating touch screen cutting assembly

A touch screen and self-lubricating technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of precision machinery occupying space and increasing equipment investment, and achieve the effects of reduced equipment cost investment, simple structure, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

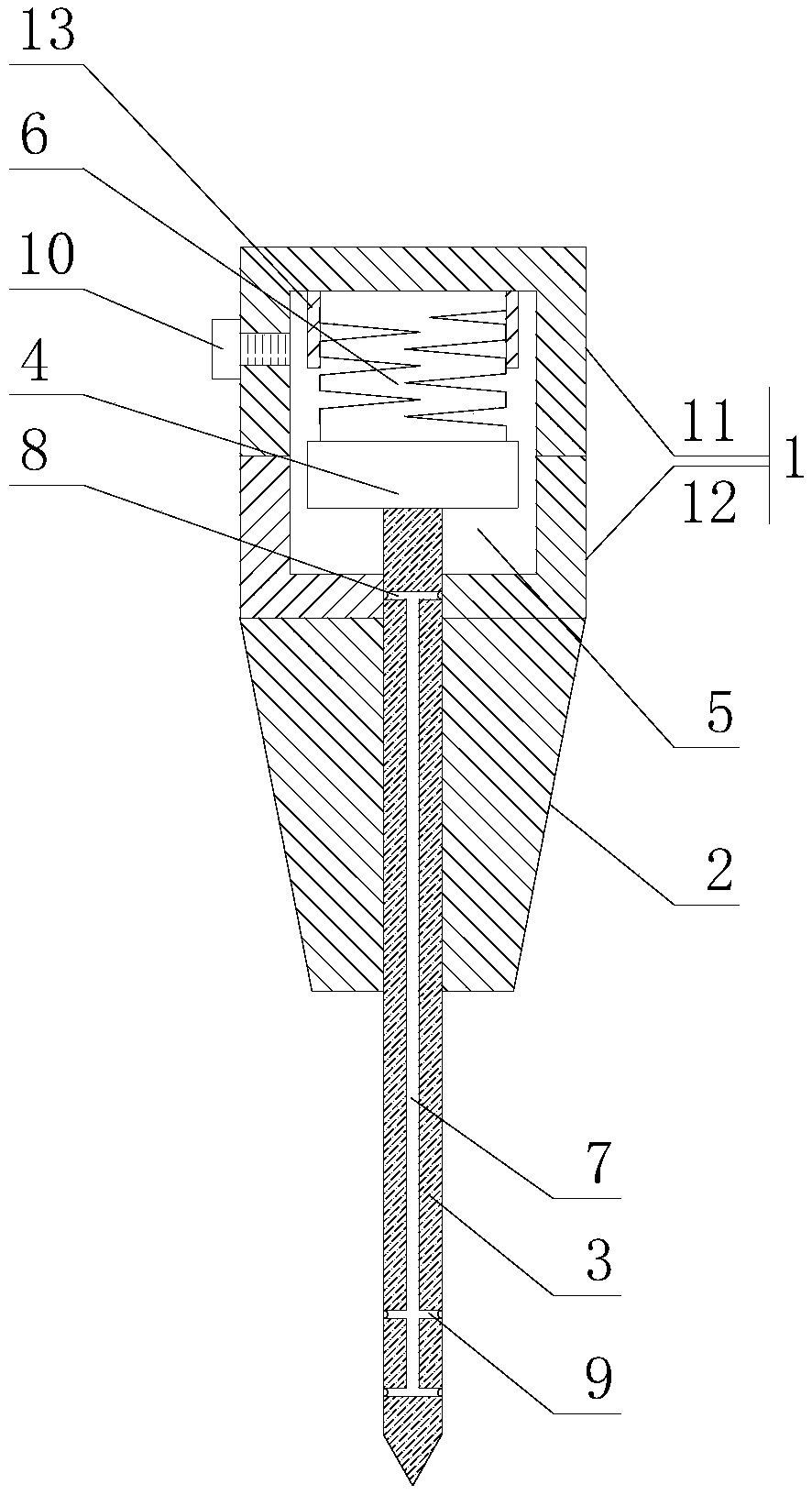

[0010] Such as figure 1 As shown, the present invention proposes a self-lubricating touch screen cutting assembly, including: oil box 1, spring 6, top plate 4, cutter 3, guide plate 2, oil box 1 has an oil chamber 5 and an opening communicating with the inside and outside of the oil chamber 5 , the guide plate 2 is fixed on the outside of the oil box 1 and has a through hole, the opening is sealed with the through hole, the spring 6 and the top plate 4 are located in the oil chamber 5, and the oil box 1, the spring 6, the top plate 4, and the tool 3 are fixed coaxially in sequence connected, the cutting end of the cutter 3 protrudes through the opening and the through hole in turn, and the cutter 3 is slidably sealed with the opening and the through hole. The hole 9 and the oil inlet hole 8 are located on the side wall of the cutter 3 close to the top plate 4, and the oil outlet hole 9 is located on the side wall of the cutting end, and when the spring 6 is in a non-stretching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com