Multifunctional structure test loading system incorporating loading tonnage and loading accuracy

A technology of structural testing and loading system, which is applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of large columns on both sides, limited test model size, and cramped test space, etc., to achieve convenient use, ensure interchangeability, The effect of strong self-locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

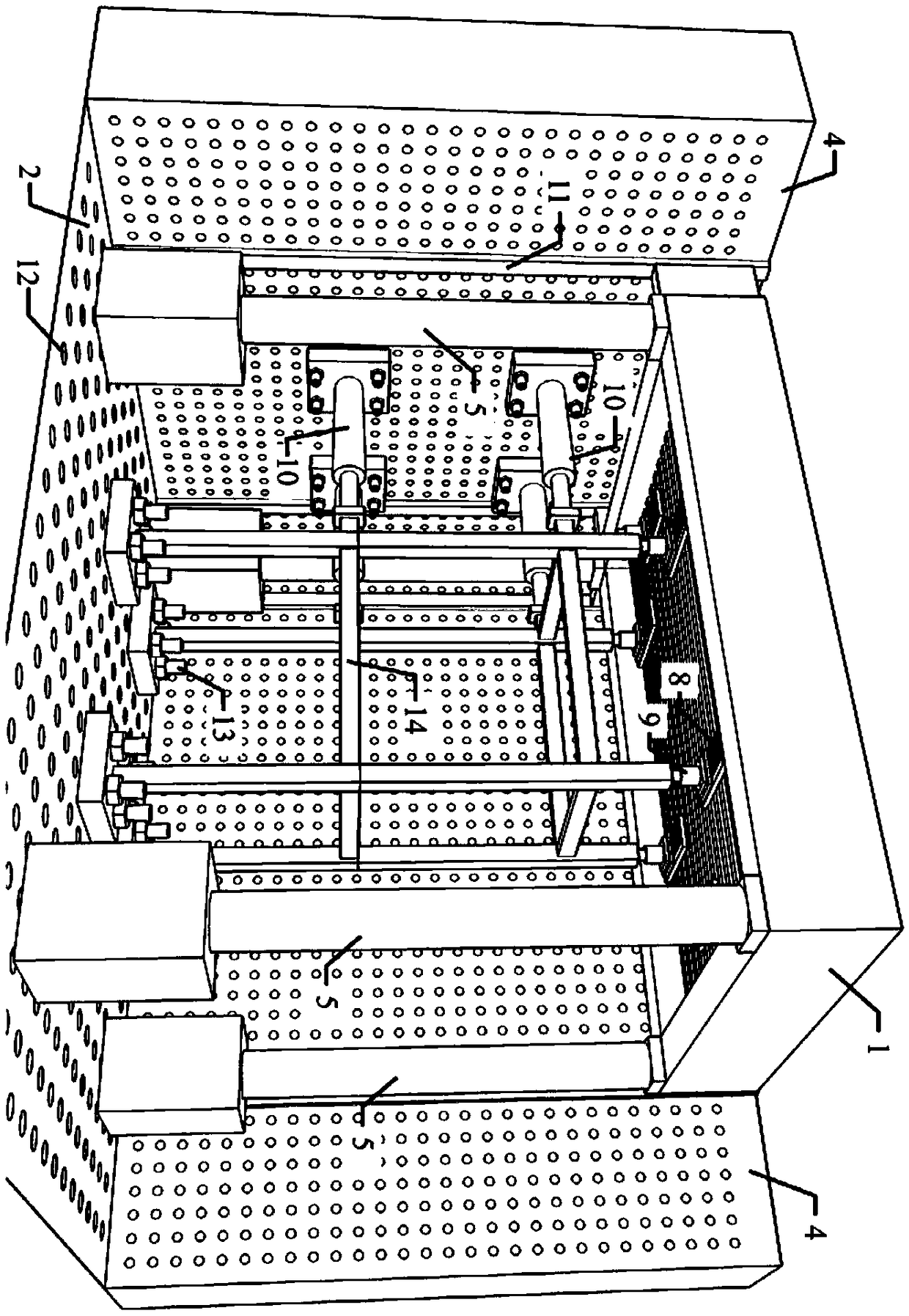

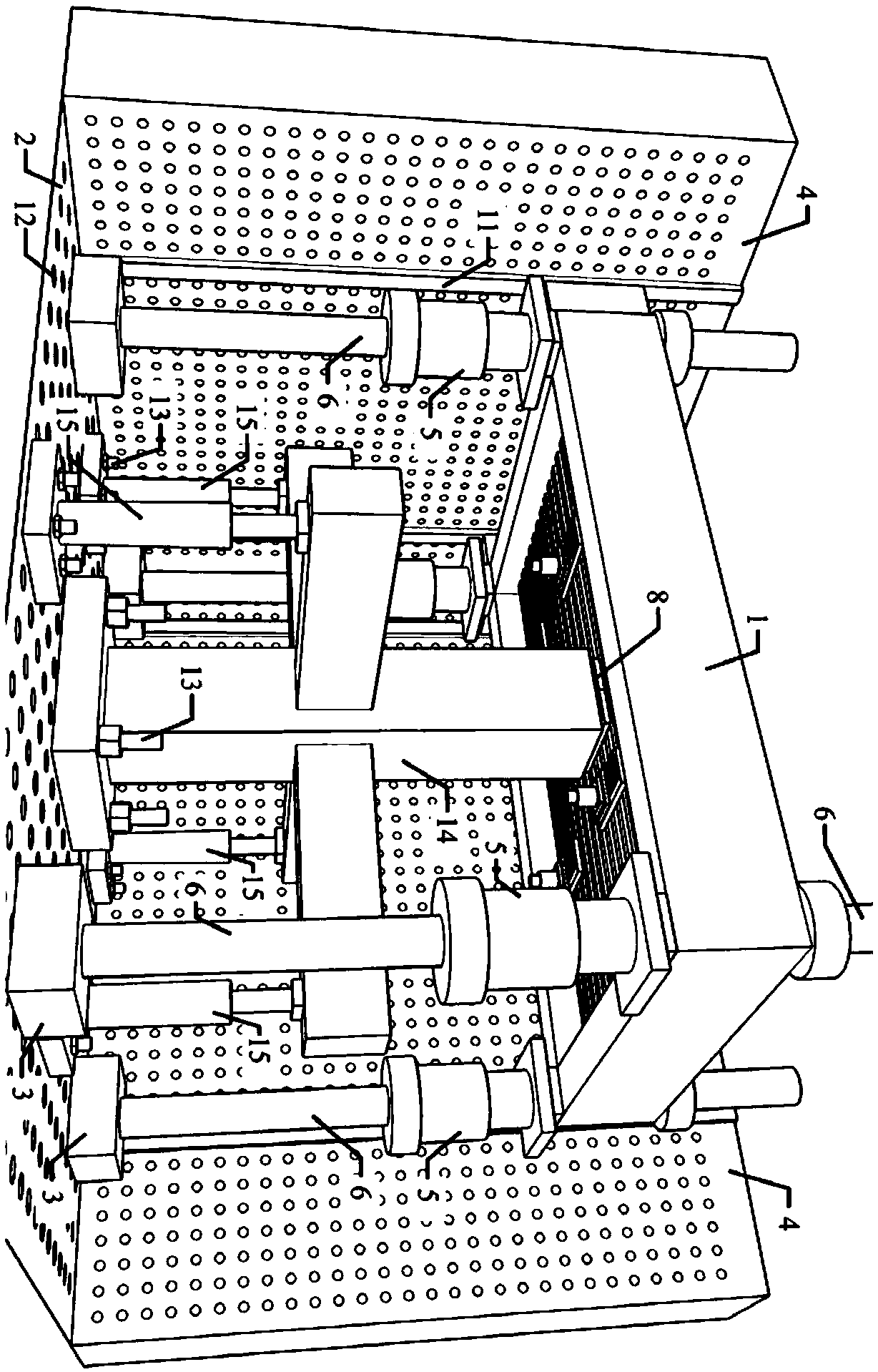

[0020] combine Figure 1-3 As shown, a multifunctional structural test loading system that takes into account the loading tonnage and loading accuracy includes a vertical loading component that can vertically load the test model 14, and also includes a main frame, and the vertical loading component is matched with the main frame. The main frame includes a fixed lateral main seat 4, a bottom reaction force base 2 with a plurality of anchor holes 12, and a plurality of anchors that can lock the test model 14 on the bottom reaction force base 2. The hole 12 matches the prestressed anchor component 13.

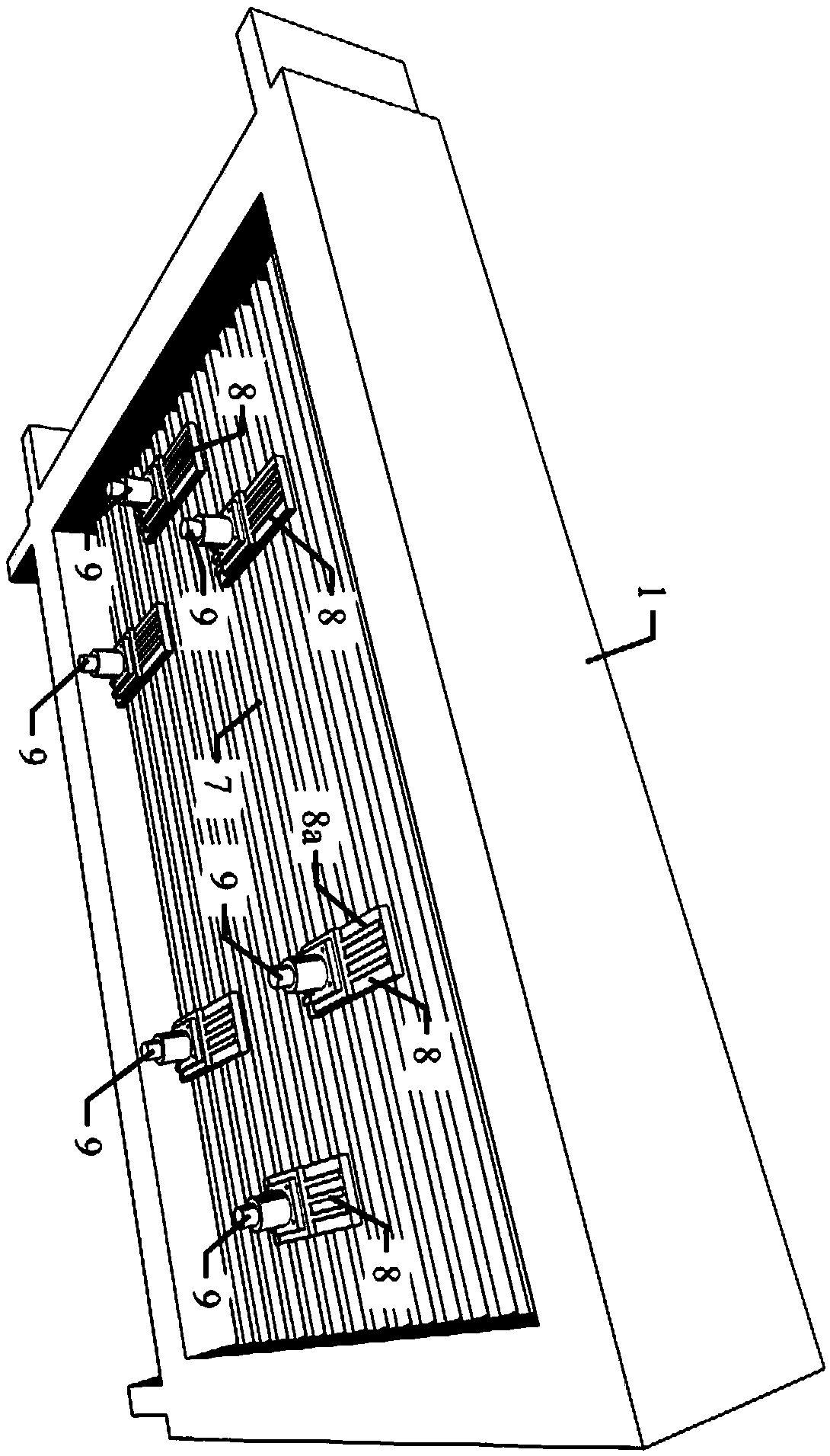

[0021] The system also includes a top steel reaction force platform 1 directly above the test model 14 , and the top steel reaction force platform 1 is vertically slidably mounted on the lateral main base 4 .

[0022] The above-mentioned vertical loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com