A safe tensile cable

A tensile and cable technology, applied in the electrical field, can solve the problems of inability to play a good fixing role, poor cable tensile strength, cable tearing, etc., to avoid excessive temperature, improve safety, and improve tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

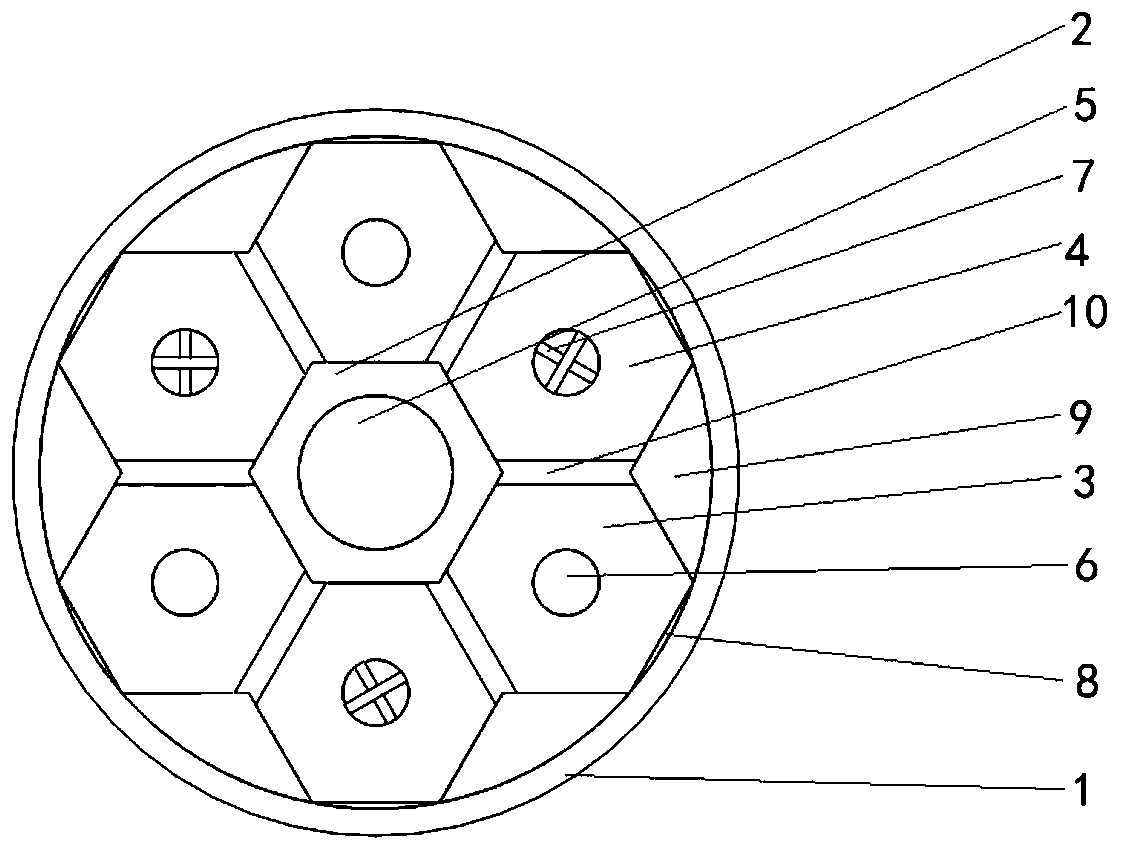

[0011] Such as figure 1 As shown, a safe tensile cable includes an insulating sheath 1, characterized in that: the center of the insulating sheath is provided with a hexagonal central tube 2, the hexagonal central tube is a regular hexagon, and Leaving an irregular hexagon next to each other can greatly reduce the occupied area and reduce the gap between the tubes in the insulating sleeve. The six faces of the central tube 2 are adjacent to the cable tube 3 and the wire tube 4. , the central tube 2, the cable tube 3 and the cable tube 4 centers are all provided with through holes, the through holes in the central tube 2 are larger than the through holes in the cable tube 3 and the cable tube 4, and the size of the through hole in the central tube is the size of the cable tube. Double the size of the hole can ensure that the stress of the aluminum wire after bending is greater than that of the copper wire stranded wire, and avoid the cable from being loose due to the stress of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com