Device for measuring temperature of electromagnetic heating device and electromagnetic heating device

A heating equipment and electromagnetic technology, applied in the direction of using electric devices, measuring devices, using electromagnetic means, etc., can solve the problems of pots not being universal, inconvenient to use, and poor thermal conductivity of glass-ceramic panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific implementation manners described here are only used to illustrate and explain the embodiments of the present invention, and are not intended to limit the embodiments of the present invention.

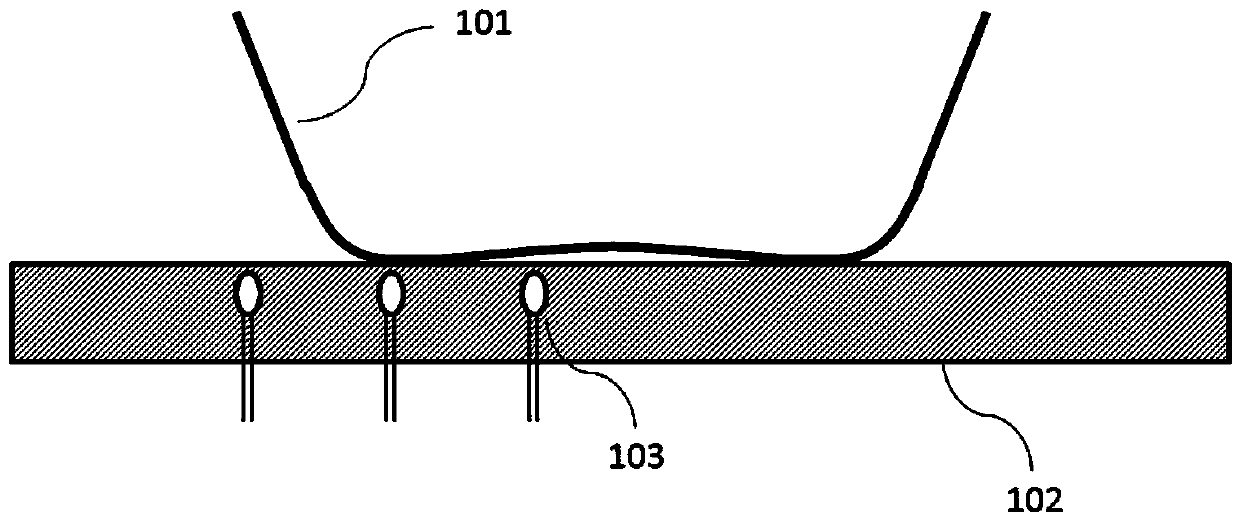

[0040] figure 1 It is a schematic diagram of a device for temperature measurement of electromagnetic heating equipment provided by an embodiment of the present invention.

[0041] like figure 1 As shown, the embodiment of the present invention provides a device for temperature measurement of an electromagnetic heating device, the electromagnetic heating device includes a panel 102 and a coil disk (not shown), the device includes: at least one microhole located in the panel 102; and a temperature sensor 103 located in at least one microwell. The pot 101 is located above the pane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com