A styling device for a wig

A styling device and wig technology, applied in wigs, applications, clothing, etc., can solve the problems of large power consumption, water and protein reduction, resource waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

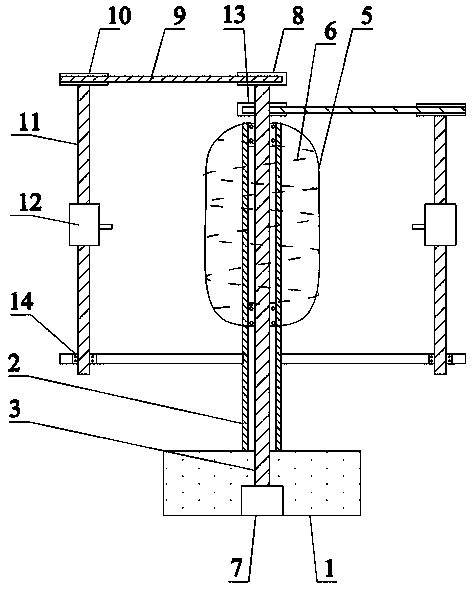

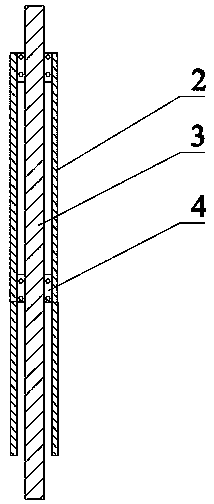

[0026] A styling device for wigs such as figure 1 As shown, it includes a base 1, a humidifying rack installed on the top of the base 1, and a humidifying mechanism installed on the humidifying rack, such as figure 2 As shown, the humidifying rack includes an outer sleeve 2 and a main shaft 3. The main shaft 3 is installed inside the outer sleeve 2 and the central axes of the two coincide. The outer sleeve 2 and the main shaft 3 are rotationally connected by a bearing I4. The bottom of the sleeve 2 is welded on the top of the base 1, and the top of the outer sleeve 2 is equipped with a mold ball 5 for placing a wig. The electric heating wire 6 is evenly wound in the mold ball 5, and the bottom end of the main shaft 3 is connected from the outer sleeve 2. After the inside of the main shaft 3 passes through the inner cavity of the base 1, it is connected to the motor 7, and the top of the main shaft 3 passes through the inside of the outer sleeve 2 and has a protruding end. The...

Embodiment 2

[0032] A styling device for wigs, comprising a base 1, a humidifying frame mounted on the top of the base 1, and a humidifying mechanism mounted on the humidifying frame, the humidifying frame includes an outer sleeve 2 and a main shaft 3, and the main shaft 3 is worn outside The inside of the sleeve 2 and the central axes of the two are coincident, the outer sleeve 2 and the main shaft 3 are rotationally connected by the bearing I4, the bottom of the outer sleeve 2 is welded to the top of the base 1, and the top of the outer sleeve 2 is installed with a Place the mold ball 5 of the wig, and the electric heating wire 6 is evenly wound in the mold ball 5. The bottom end of the main shaft 3 passes through the inside of the outer sleeve 2 and is connected with the motor 7 arranged in the inner cavity of the base 1. The top end passes through the inside of the outer sleeve 2 and has a protruding end. A driven wheel I8 is installed on the outside of the protruding end. The driven wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com