Anesthetic face mask suitable for inspection tubes of various specifications

An anesthesia mask and face mask technology, applied in the field of anesthesia masks, can solve the problems of oxygen leakage, high friction, and difficult operation of inspection tubes, and achieve the effects of smooth operation, convenient use, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

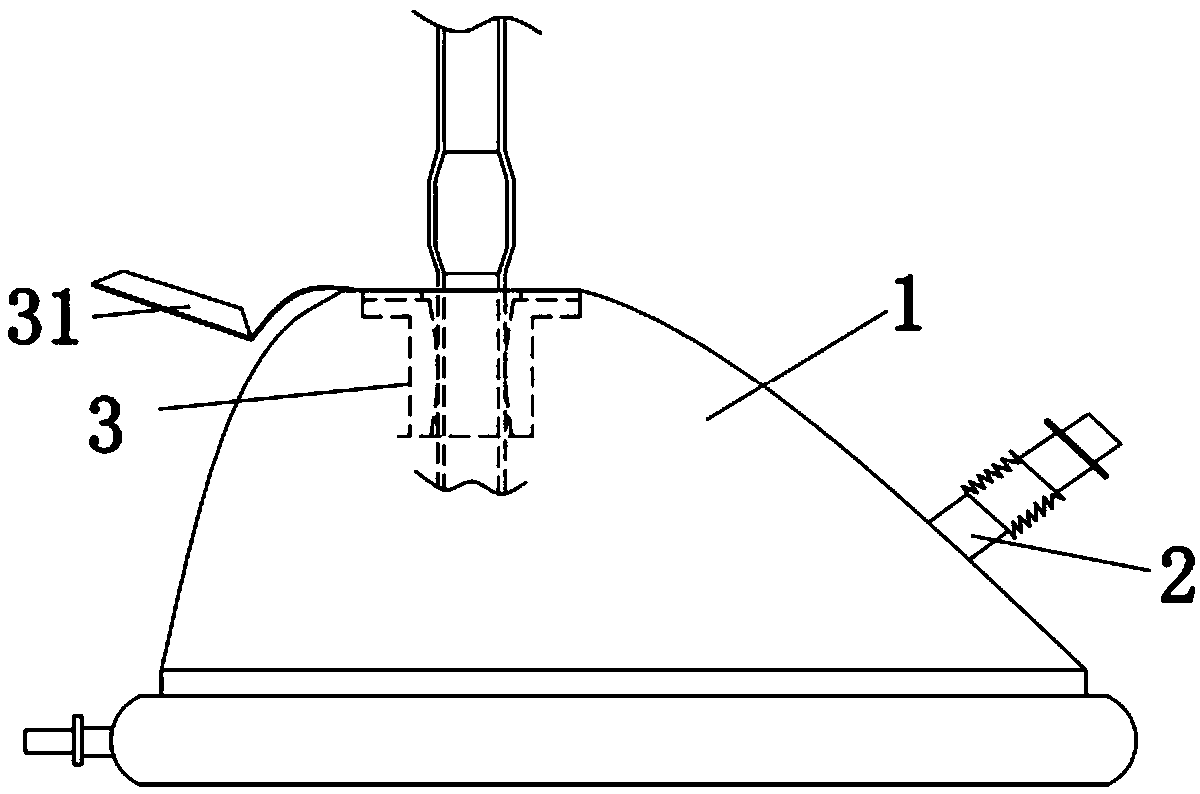

[0024] In this example, if Figure 1-2 As shown, this embodiment provides an anesthesia mask suitable for inspection tubes of various specifications, including a mask body 1, an oxygen inhalation tube 2 arranged on the mask body 1, and an inspection tube installed on the mask body 1. Check channel 3.

[0025] In this embodiment, by connecting the inspection channel 3 with the mask body 1, when the inspection channel 3 is not inserted into the inspection tube, the mask body 1 does not leak and has a sealing function; its upper end is provided with a sealing cap 31, which is not inserted. When inspecting the tube, the sealing cap 31 covers the inspection channel 1, so that the mask body 1 is in a sealed state.

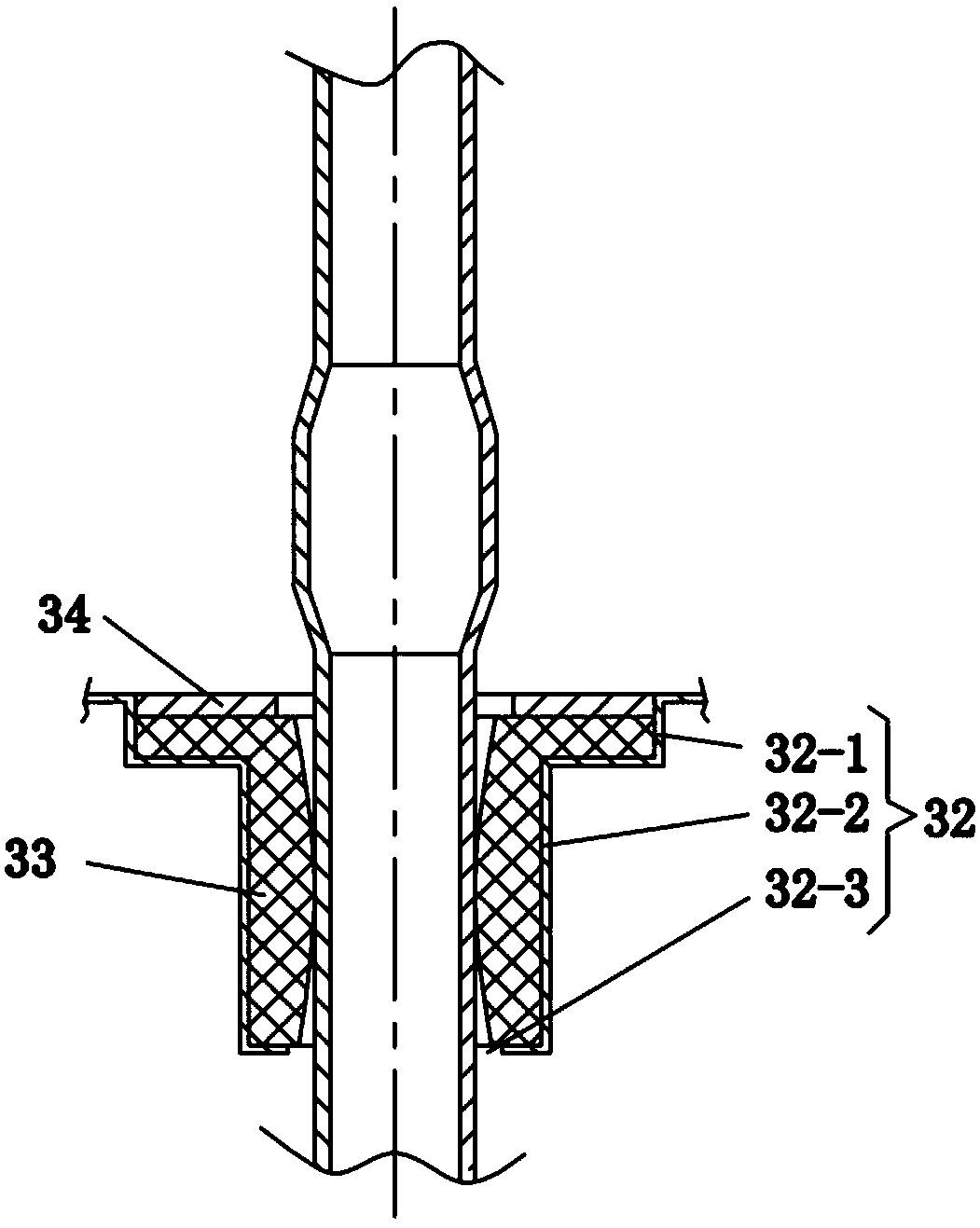

[0026] In this embodiment, by designing an elastic opening 32 at the lower end of the inspection channel 3, the large-diameter sections of inspection tubes of various specifications or reduced-diameter inspection tubes also have smooth and sealing functions when inserte...

Embodiment 2

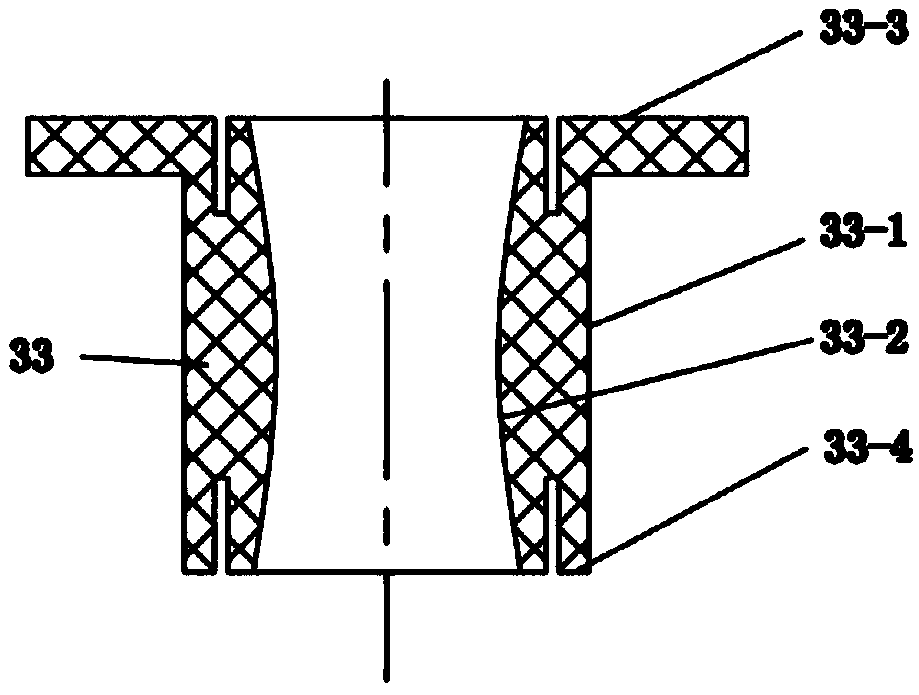

[0034] Such as image 3 As shown, in order to prevent the deterioration of the elastic performance when the coarse inspection tube enters the sealing elastic body 33 and is squeezed as a whole, the upper and lower walls (33-3, 33-4) can be provided with grooves, The upper and lower ends of the inner wall surface 33-2 are made of elastic body.

Embodiment 3

[0036] Such as Figure 4 As shown, in order to make the sealing elastic body 33 more elastic and reduce frictional resistance when in contact with the inspection tube, the shape of the inner wall surface 33-2 can be designed as a sawtooth structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com