Rolling mill structure

A rolling mill and roller technology, applied in the field of rolling mill structure, can solve the problems of high manufacturing cost, large power consumption, low production efficiency, etc., and achieve the effects of low manufacturing cost, high production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

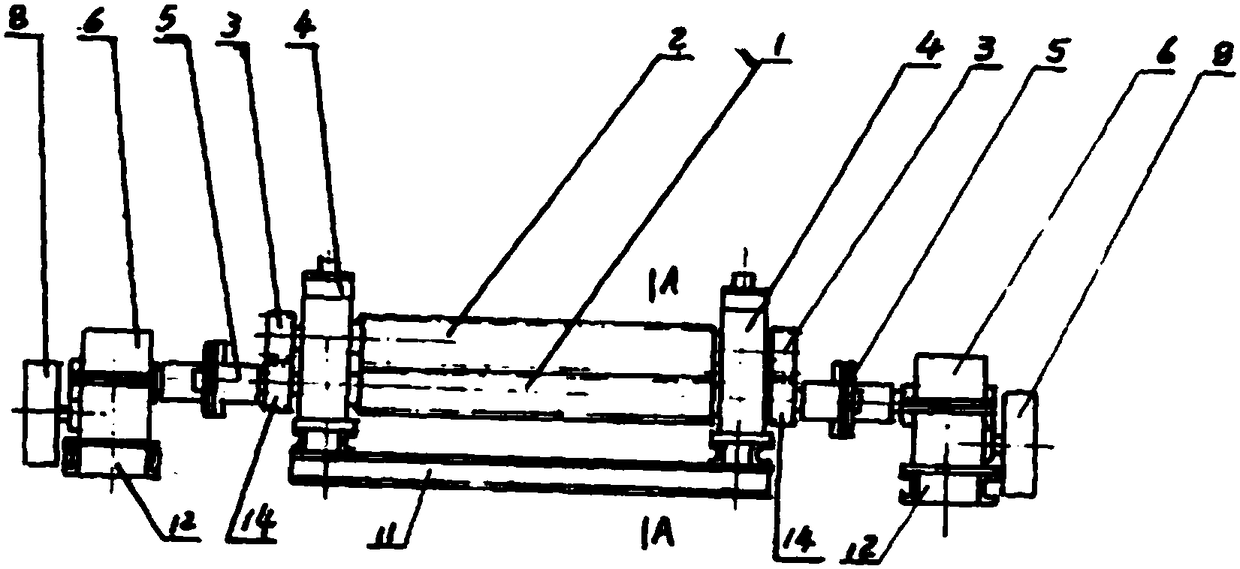

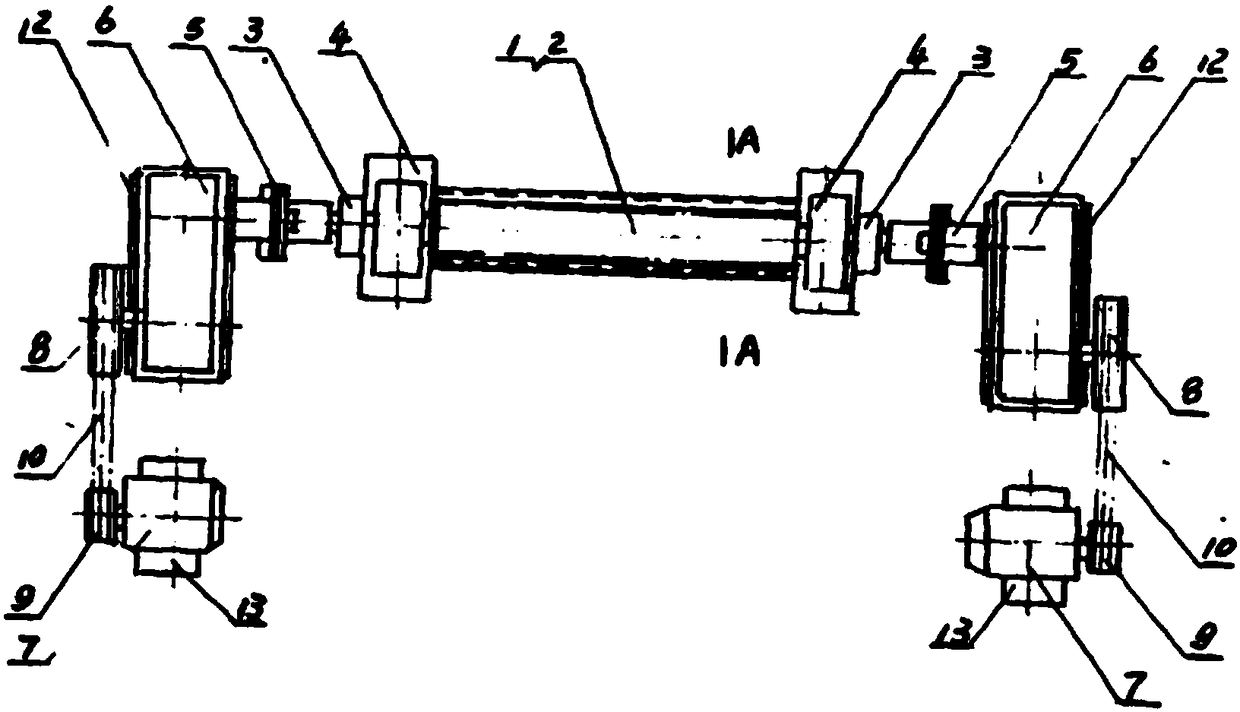

[0013] Reference figure 1 , The rolling mill structure of the present invention includes an active roll 1, a passive roll 2, a shaft frame 4, and a frame frame 11. The passive roll 2 is mounted on the shaft frame 4, the shaft frame 4 is fixed on the frame 11, and the motor 7 passes The reducer is connected with the driving roller shaft 1. The gear 13 fixed on the driving roller shaft 1 meshes with the gear 14 fixed on the passive roller shaft. The gap between the tooth meshing parts provided on the driving roller 1 and the passive roller 2 is for the rolling plate The material opening is characterized in that: the lower end of the frame 11 is provided with a shock-absorbing pad; a shock-absorbing pad iron is arranged between the shaft bracket 4 and the frame 11. The base 12 is fixed on the floor, and a shock-absorbing horn is arranged between the base 12 and the floor.

[0014] The reducer is connected by a belt pulley 9 to a belt pulley 8 at the input shaft end of the gearbox 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com