Follow-up gravity compensation device of three-degree-of-freedom space station cloud lamp

A technology of gravity compensation and space station, which is applied in the field of aerospace, can solve problems such as inability to completely simulate lighting equipment, and achieve the effects of avoiding bending moment, high assembly accuracy, and high unloading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

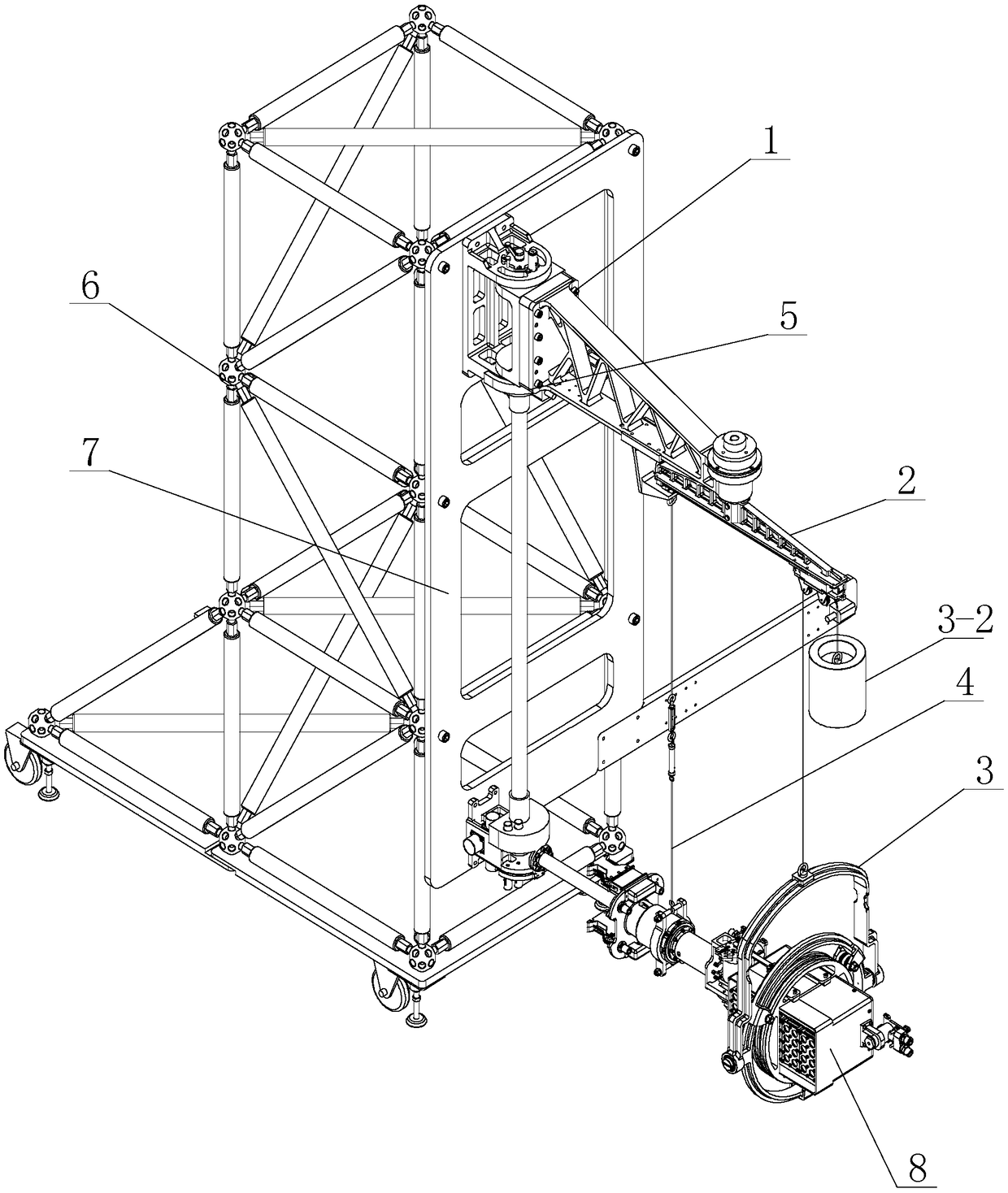

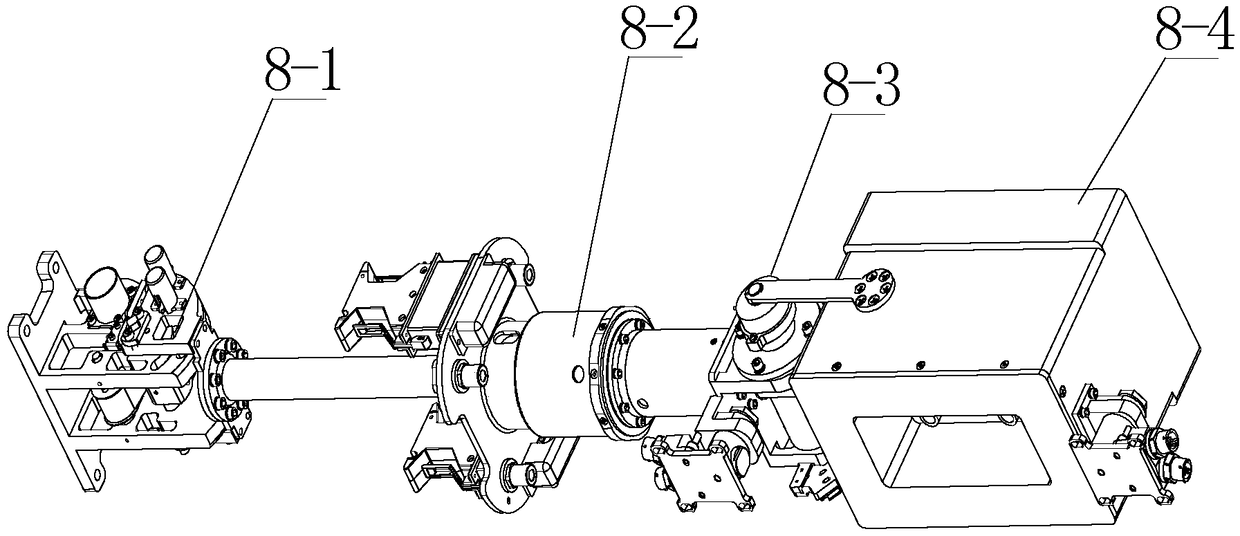

[0019] Specific implementation mode one: combine figure 1 and figure 2 Describe the present embodiment, a follow-up gravity compensation device for a three-degree-of-freedom space station pan table lamp described in this embodiment, which includes a synchronous compression release assembly 5, a spherical support frame 6 and a positioning plate 7, and the positioning plate 7 is vertically fixed On the spherical support frame 6, this embodiment also includes a boom assembly 1, a forearm assembly 2, a front end refill assembly 3 and a rear end refill assembly 4, the boom assembly 1 is connected with the positioning plate 7, the forearm assembly 2 is connected with the The boom assembly 1 is connected, the front end of the forearm assembly 2 is connected to the projection lighting equipment 8 through the front refill assembly 3, and the rear end of the forearm assembly 2 is connected to the middle part of the projection lighting equipment 8 through the rear refill assembly 4, Th...

specific Embodiment approach 2

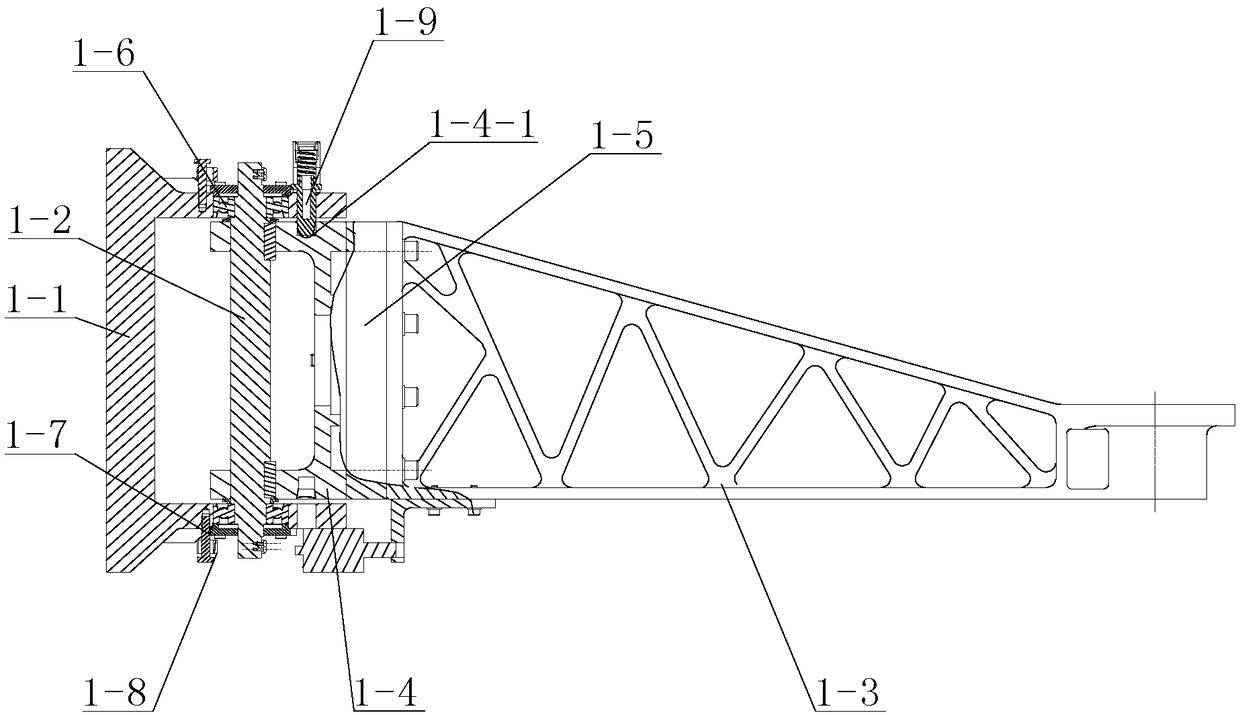

[0022] Specific implementation mode two: combination image 3 Describe this embodiment, the arm assembly 1 of a follow-up gravity compensation device for a three-degree-of-freedom space station pan table light described in this embodiment includes a base 1-1, a rotary shaft 1-2, an arm 1-3 and an arm assembly 1. The arm rotary support 1-4, the base 1-1 is fixedly installed on the positioning plate 7, the end of the boom 1-3 is connected with the boom rotary support 1-4, and the boom rotary support 1-4 passes through the rotary shaft 1-2 is rotationally connected with the base 1-1.

[0023] An adjustment cushion block 1-5 is provided at the junction of the boom slewing support 1-4 and the end of the boom 1-3.

[0024] The upper end and the lower end of the rotary shaft 1-2 are provided with angular contact ball bearings 1-6.

[0025] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination image 3 To illustrate this embodiment, the boom assembly 1 of a follow-up gravity compensation device for a three-degree-of-freedom space station pan table light described in this embodiment also includes two gear shafts 1-7 and two constant moment springs 1-8, basically The upper end and the lower end of the seat 1-1 are respectively provided with a retaining shaft 1-7, and each retaining shaft 1-7 is equipped with a constant moment spring 1-8 respectively. The constant torque spring 1-8 is made of 3Cr19Ni9Mo2N material, which has excellent comprehensive performance, good surface quality, strict control of surface defects and decarburization, and precise shape and size. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com