Drop type automatic bagging machine

A bagging machine, drop-type technology, applied in the direction of packaging automatic control, packaging, transportation packaging, etc., can solve the problems of error-prone, labor-intensive workers, low efficiency, etc., achieve small footprint, simple structure, reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

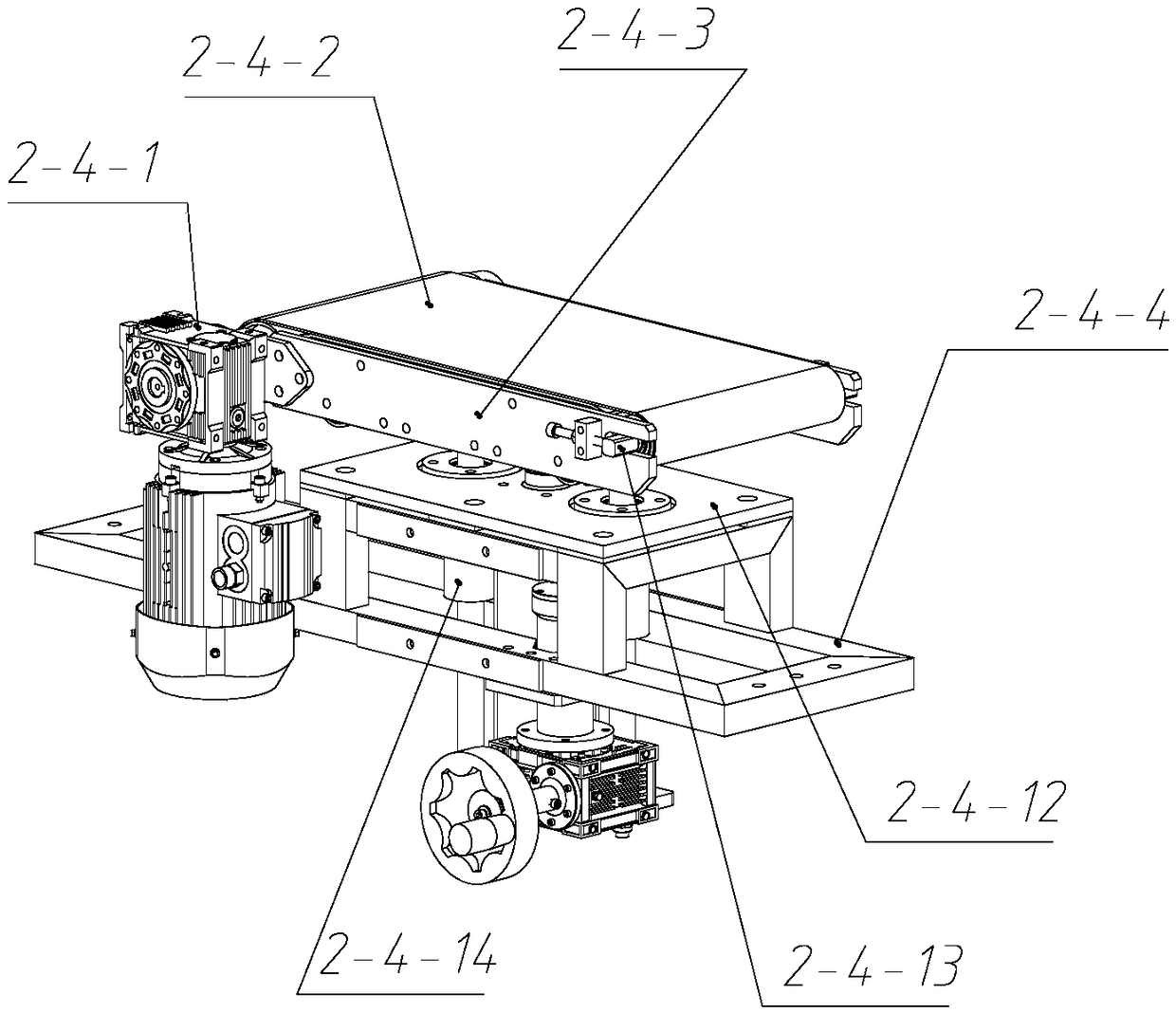

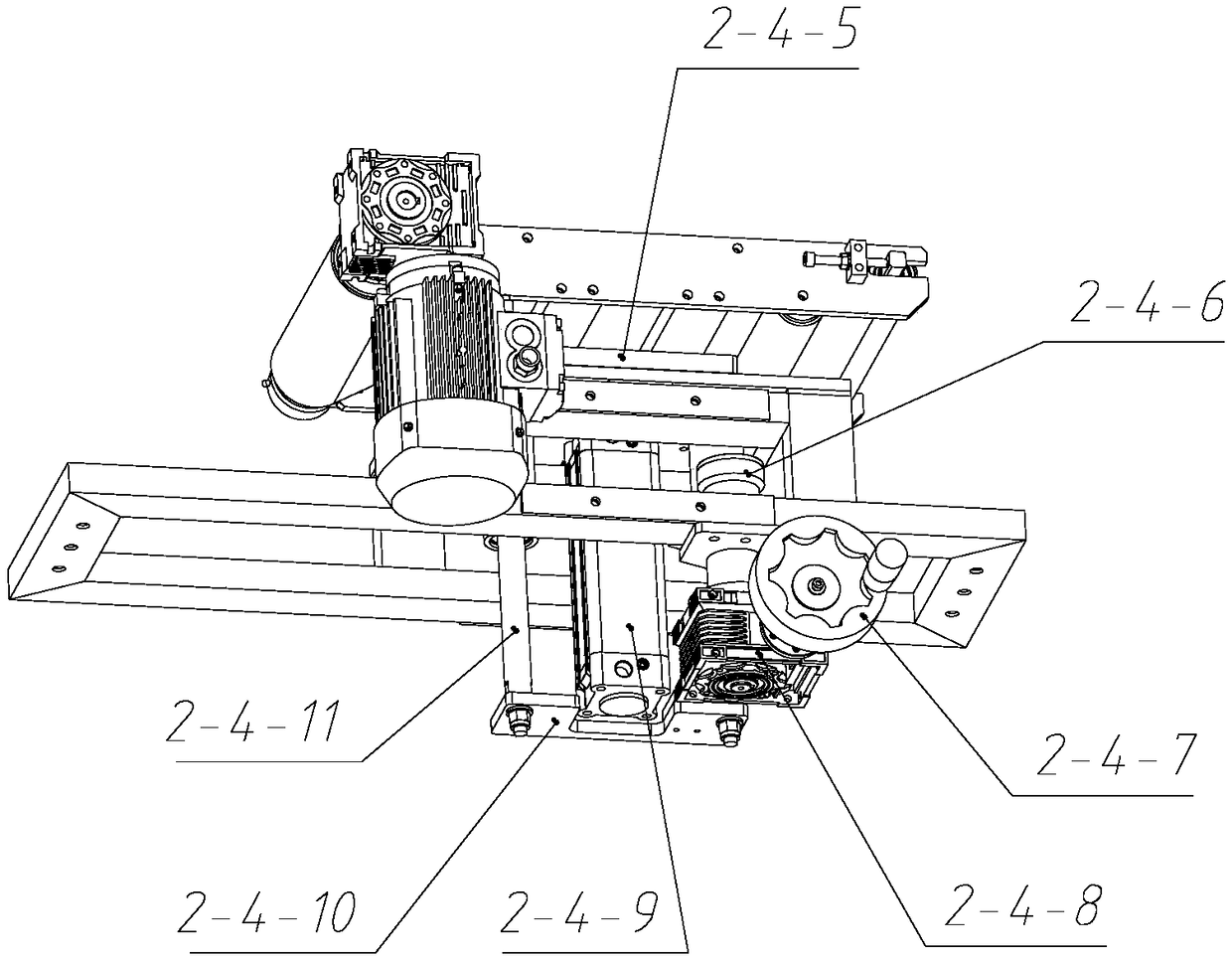

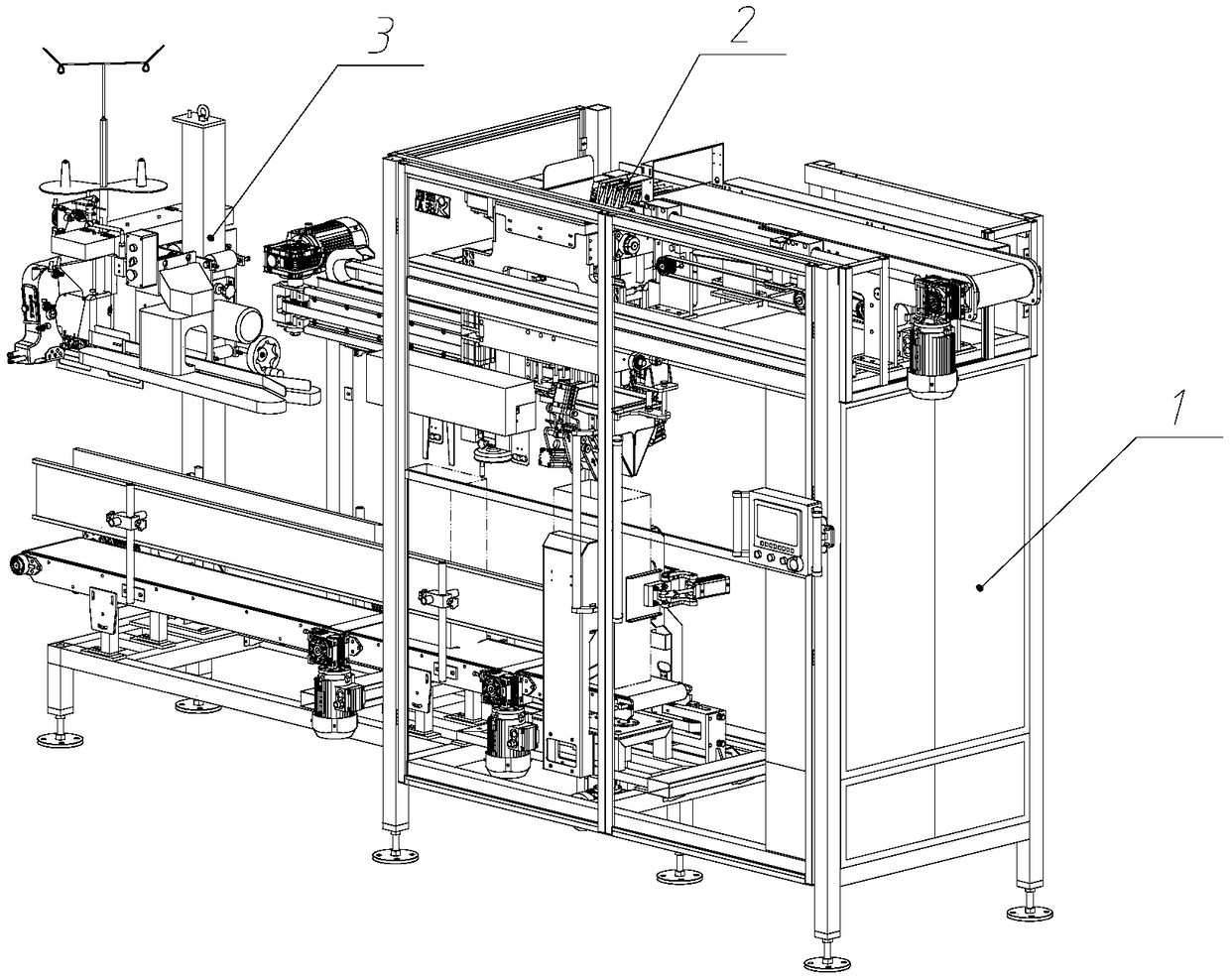

[0047] refer to Figure 1 to Figure 17 As shown, the drop-type automatic bagging machine in an embodiment provided by the present invention includes a bagging part 2 and a traction sewing part 3, and the output end of the bagging part 2 is docked with the input end of the traction sewing part 3;

[0048] Further, the drop-type automatic bagging machine also includes a frame part 1, the bagging part 2 and the traction sewing part 3 are all arranged on the frame part 1, and the bagging part 2 is arranged on the side of the traction sewing part 3 upper end.

[0049] The integral frame part 1 at least includes a large frame 1-1, a control system 1-2, a control panel assembly 1-3, an end face shield 1-4, a protective door 1-5 and a big foot 1-6. Its main feature is that the control system 1-2 is embedded in the large frame 1-1, and the outside is flush w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com