Numerically-controlled coiled material slicing machine

A slicing machine and coil technology, which is applied in the directions of sending objects, thin material processing, transportation and packaging, can solve the problems of low precision, time-consuming and laborious, and large deviation of finished products, and achieves reasonable structure, simple and convenient operation, and improved precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

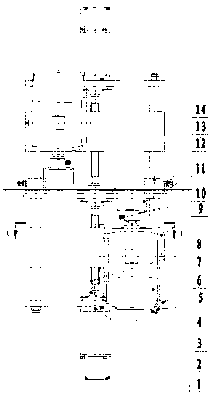

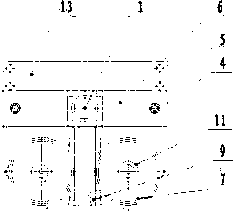

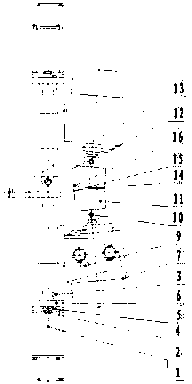

[0019] The numerically controlled coil slicer of the present invention comprises a PLC control system, a constant tension unwinding mechanism, a pressing mechanism, a gripper mechanism, a conveyor belt mechanism and an automatic cloth cutting knife. The PLC control system includes PLC, touch screen, servo controller and related control appliances; through PLC programming, touch screen operation and control of servo controller and other electrical components to realize parameter setting, action operation and so on. The constant tension unwinding mechanism includes a frame 1, a brake mounting seat 2, a brake 3, an air expansion shaft seat 4, an air expansion shaft 5, a material 6, a vertical seat bearing I7, and a cloth guide roller 8; The shaft seat 4 is fixedly installed on the frame 1, the air expansion shaft 5 equipped with the material 6 is supported and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com