Lead screw type steering machine capable of being quickly installed and disengaged

A direction machine and fast technology, applied in the direction of mechanical equipment, transmission device, transmission device parts, etc., can solve the problems of large weight and volume, cumbersome fixing and release, etc., to achieve the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

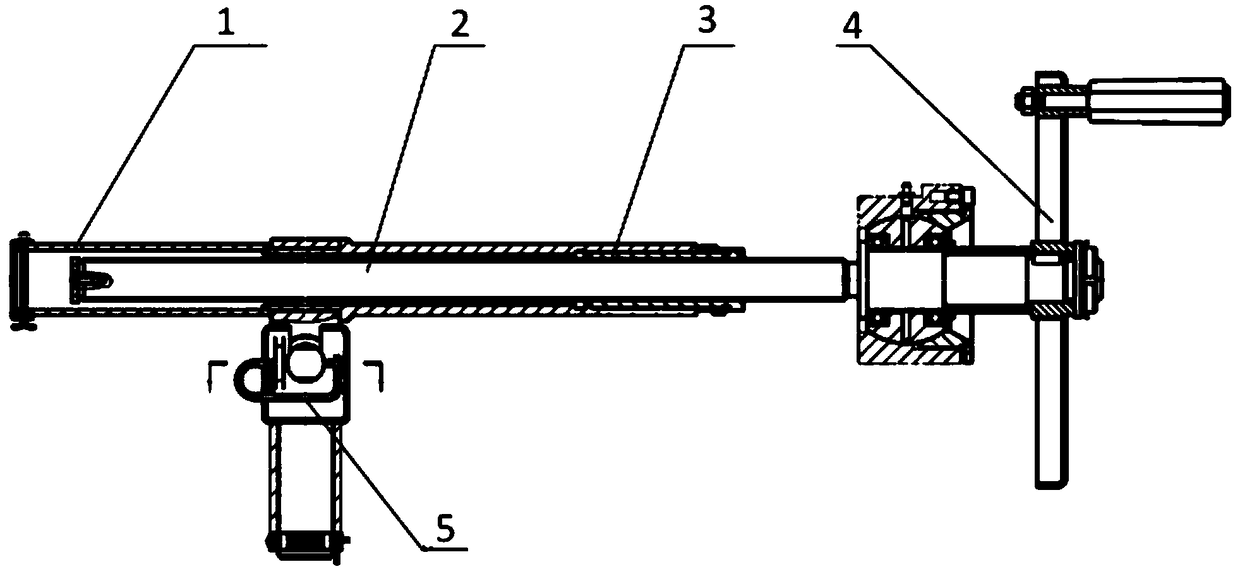

[0010] The present invention provides a screw-type steering machine that can be quickly installed and released, including a fixed cylinder 1, a screw 2, a screw sleeve 3, a hand wheel 4, and a quick coupling device 5;

[0011] The hand wheel is fixed at one end of the lead screw, the other end of the lead screw is set in the fixed barrel, the middle part of the lead screw cooperates with the screw sleeve fixed on the fixed barrel to realize the adjustment of the relative position between the upper and lower racks;

[0012] The quick coupling device is fixedly connected with the lower frame, and one side of the fixed cylinder is provided with an extending end, which is connected with the quick coupling device;

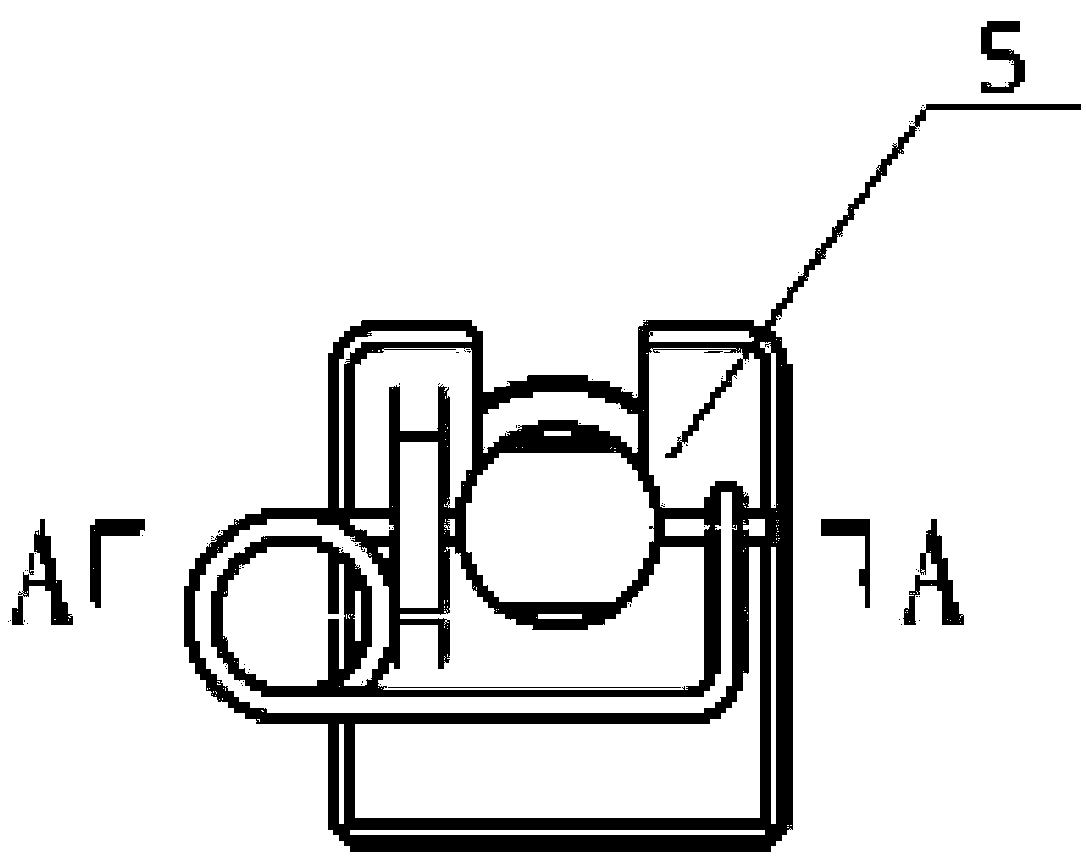

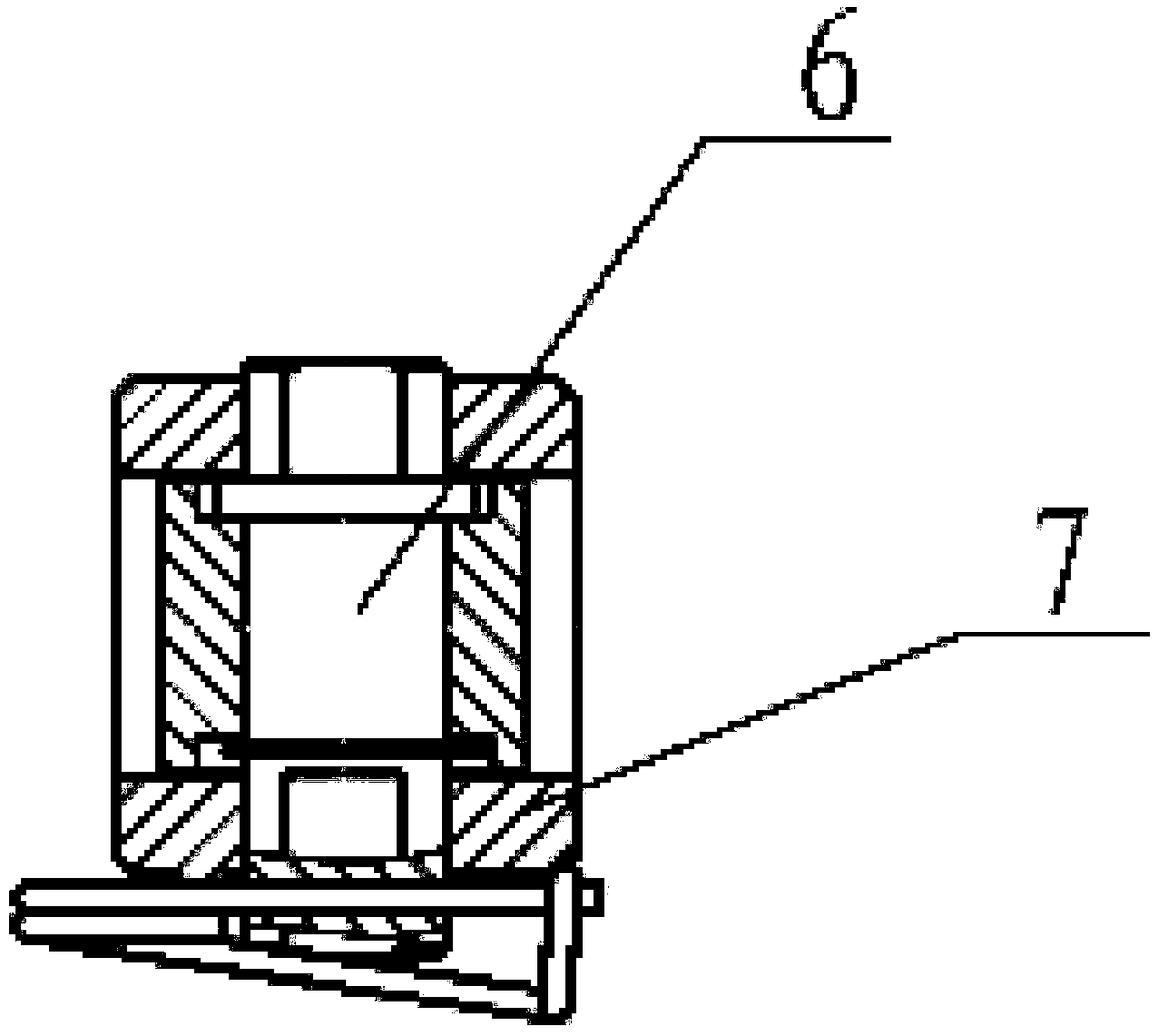

[0013] The quick coupling device includes a rotating shaft 6, a lower frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com