Crawler belt clamping structure of warehouse of vending machine

A crawler and machine cargo technology, which is applied in the field of crawler clamping structure in the vending machine warehouse, can solve the problems of prolonged assembly time, troublesome track position adjustment, long time-consuming maintenance and replacement, etc., and achieve the effect of saving installation and disassembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

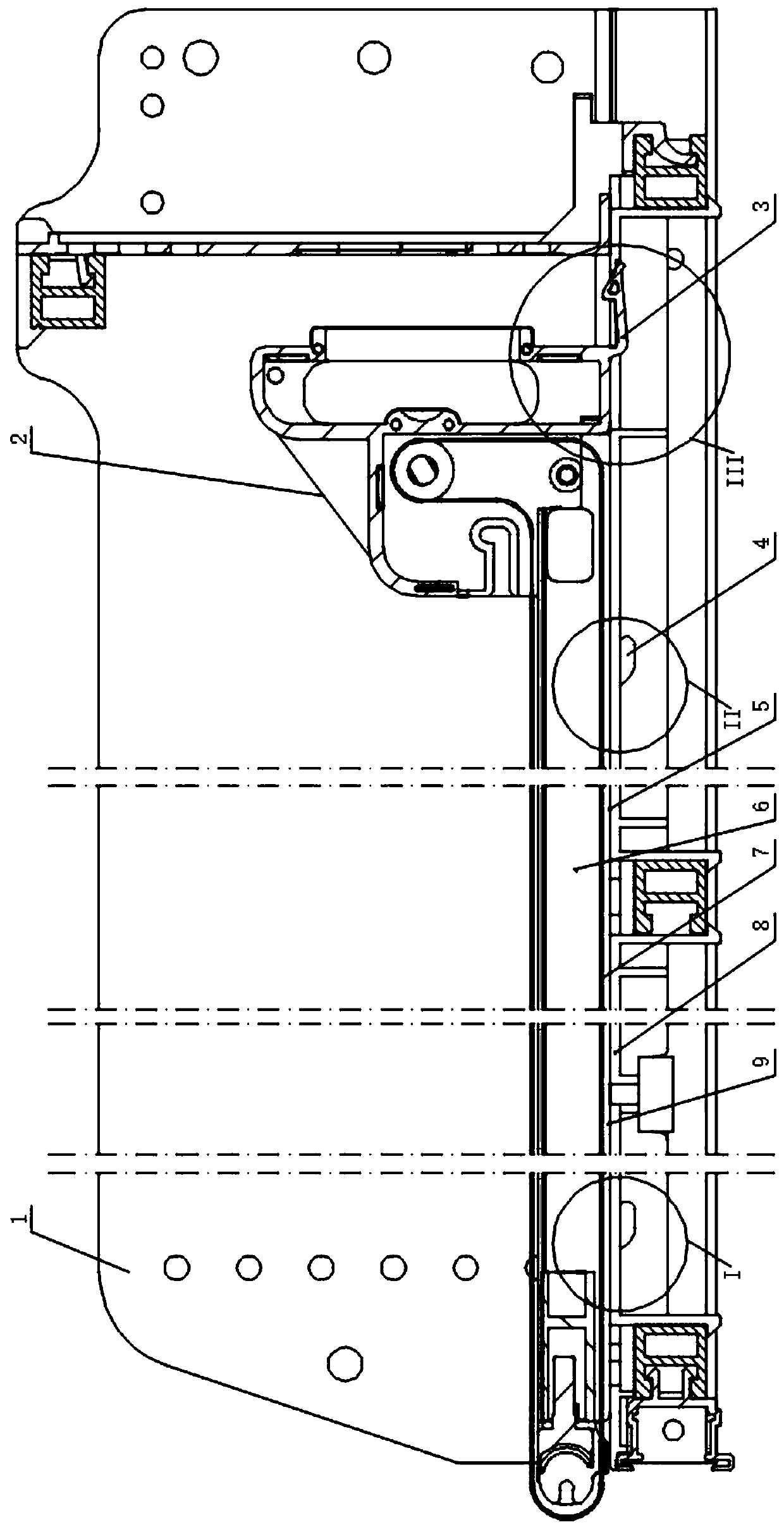

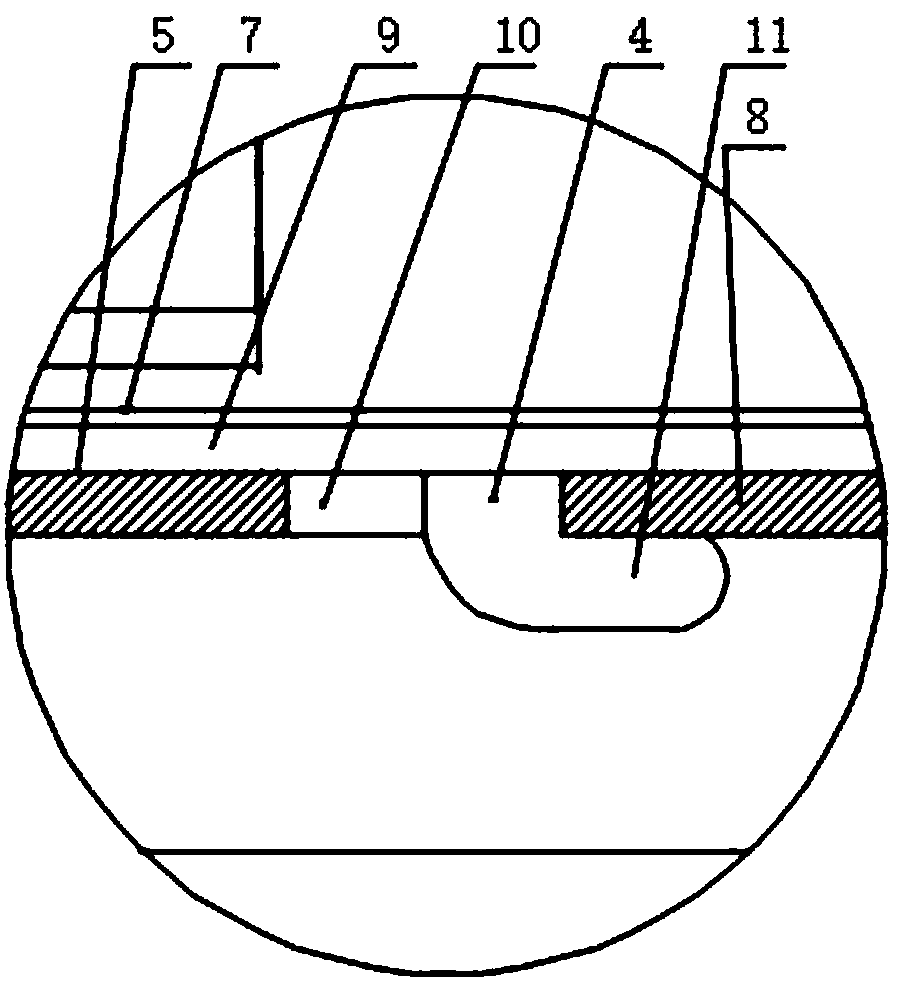

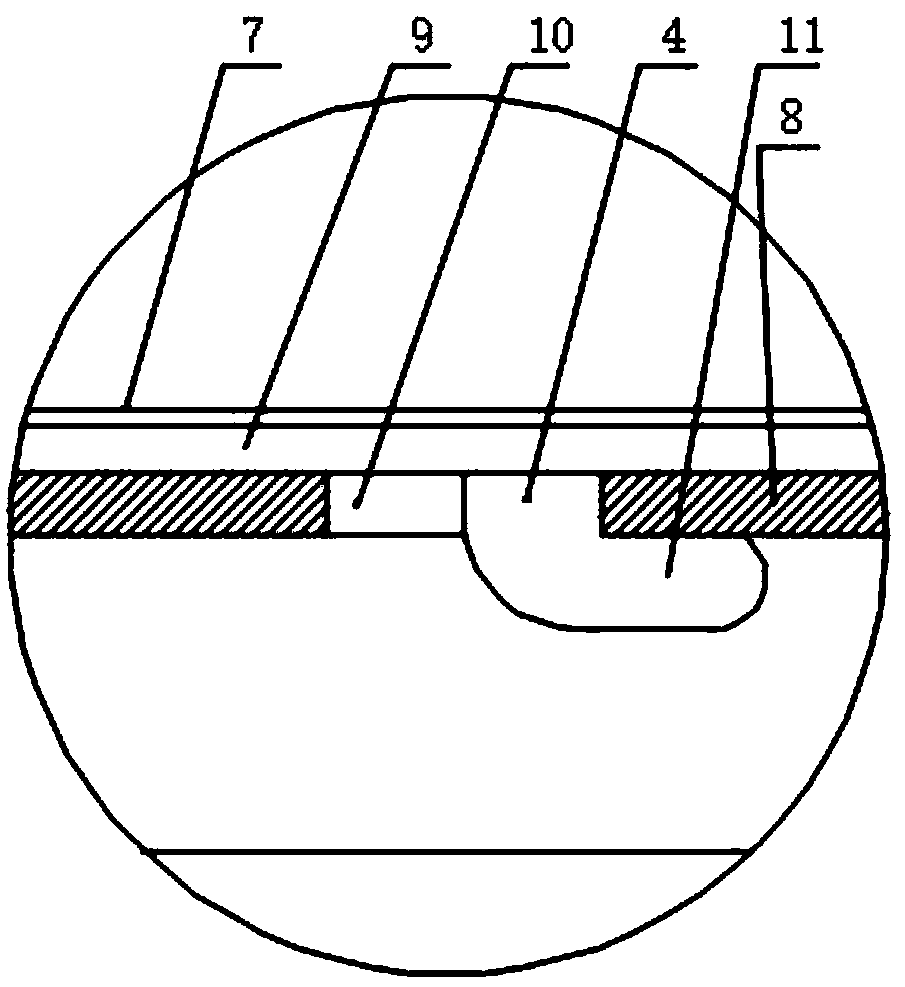

[0017] A vending machine warehouse crawler clamping structure, such as Figure 1~4 As shown, it includes a warehouse 1, a crawler belt 2 and a base plate 8, and the base board is installed at the lower end of the warehouse. The innovation of the present invention is that the lower ends 9 on both sides of the bracket 6 of the crawler belt are respectively provided with at least one belt extending from the front end to the rear end. The bending buckle 4 is provided with an elastic piece 3 extending toward the rear end at the rear end of the bracket, and the bending buckle and the elastic piece can be stuck on the surface of the substrate when the bracket moves backward.

[0018] In this embodiment, slots 10 are provided on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com