Switching temperature control valve core

A temperature control valve and switching rod technology, applied in temperature control, valve details, multi-port valves, etc., can solve the problems of inability to achieve modular production, high cost, and inconvenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

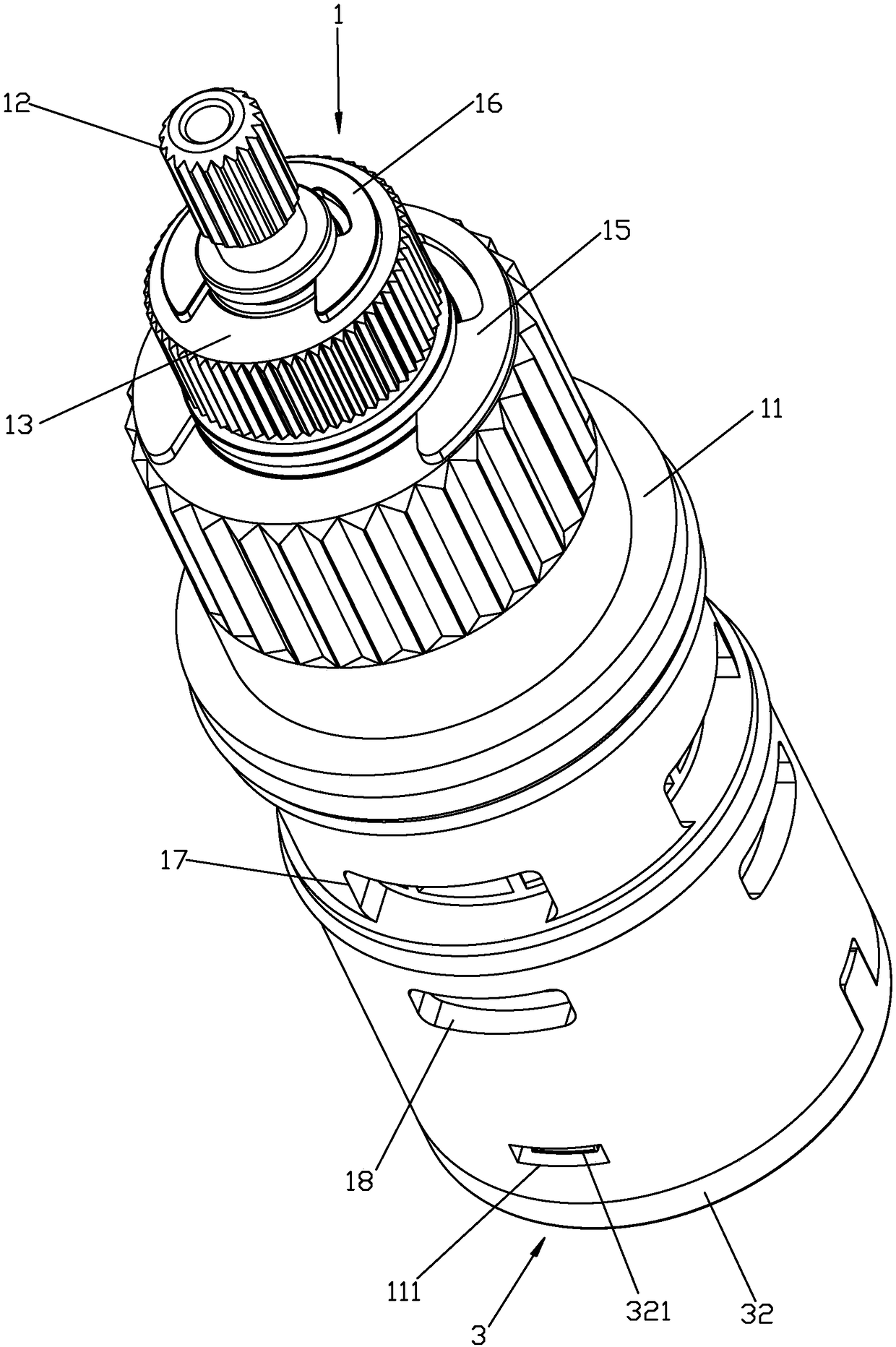

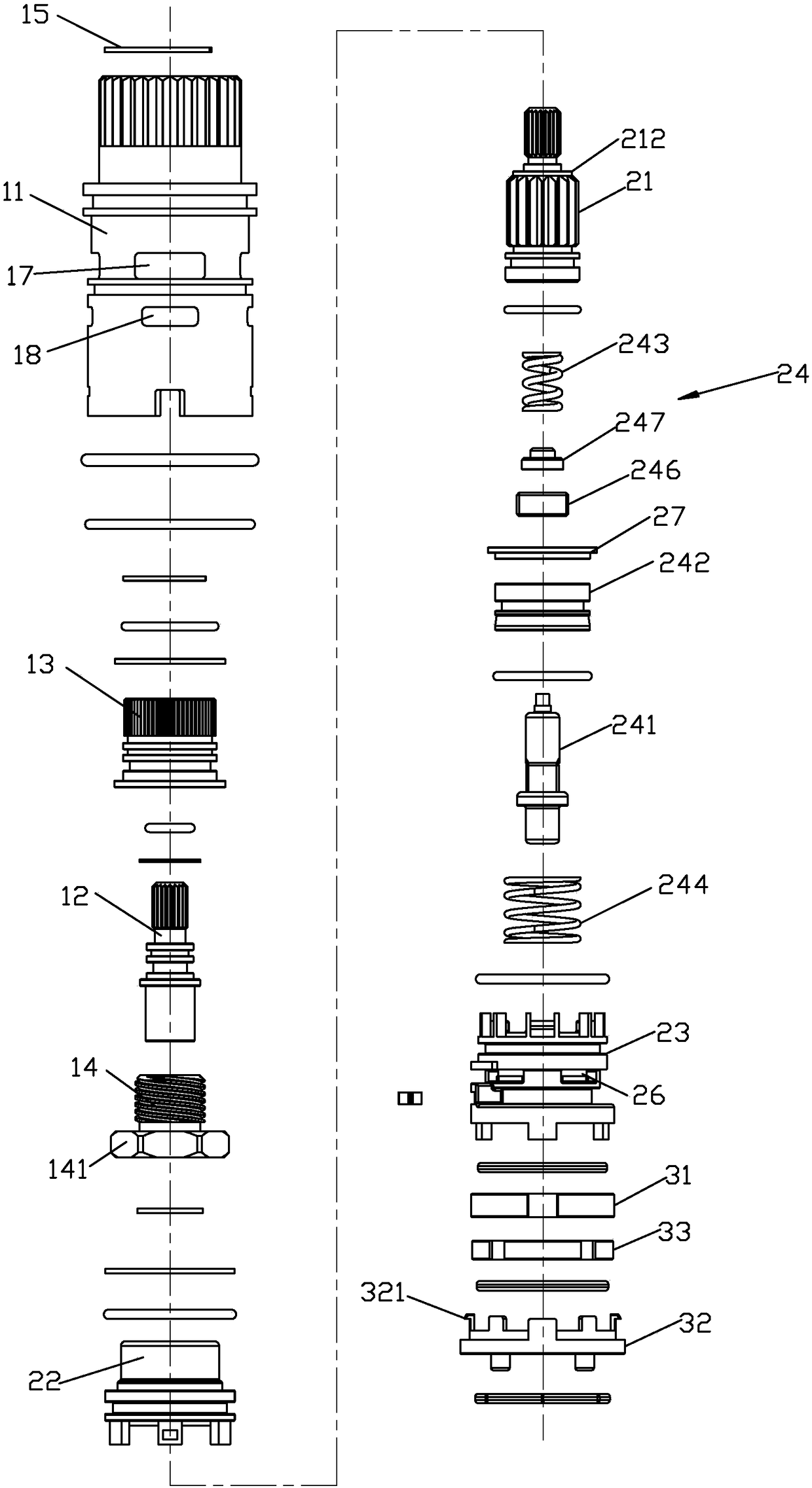

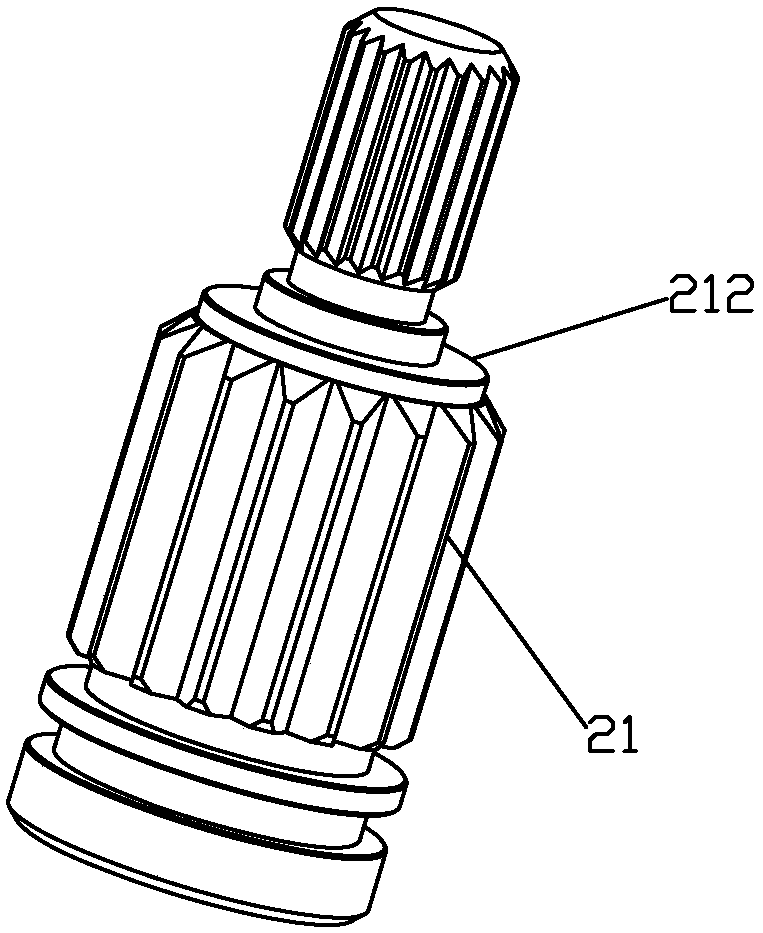

[0038] Please refer to the attached Figure 1 to Figure 14 , to switch the temperature control spool, including a regulating component 1, a temperature regulating component 2 and a switching component 3.

[0039] The adjustment assembly 1 includes a casing 11, a switch lever 12, a temperature regulation sleeve 13 and a sliding seat 14. Axially slidably arranged in the housing 11, the temperature regulation sleeve 13 and the slide seat 14 cooperate to drive the slide seat 14 to slide through the rotation of the temperature regulation sleeve 13; the temperature regulation sleeve 13 is provided with internal threads, and the slide seat 14 is provided with external threads , the temperature regulation sleeve 13 and the slide seat 14 are screwed together, and the slide seat 14 can be rotatably socketed outside the switching rod 12, so that the temperature regulation cover 13 can drive the slide seat 14 to slide. In a specific structure: the lower peripheral edge of the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com