Arc-extinguishing structure of direct-current contactor

A DC contactor and arc extinguishing technology, applied in relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems such as continuous arcing of arcs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

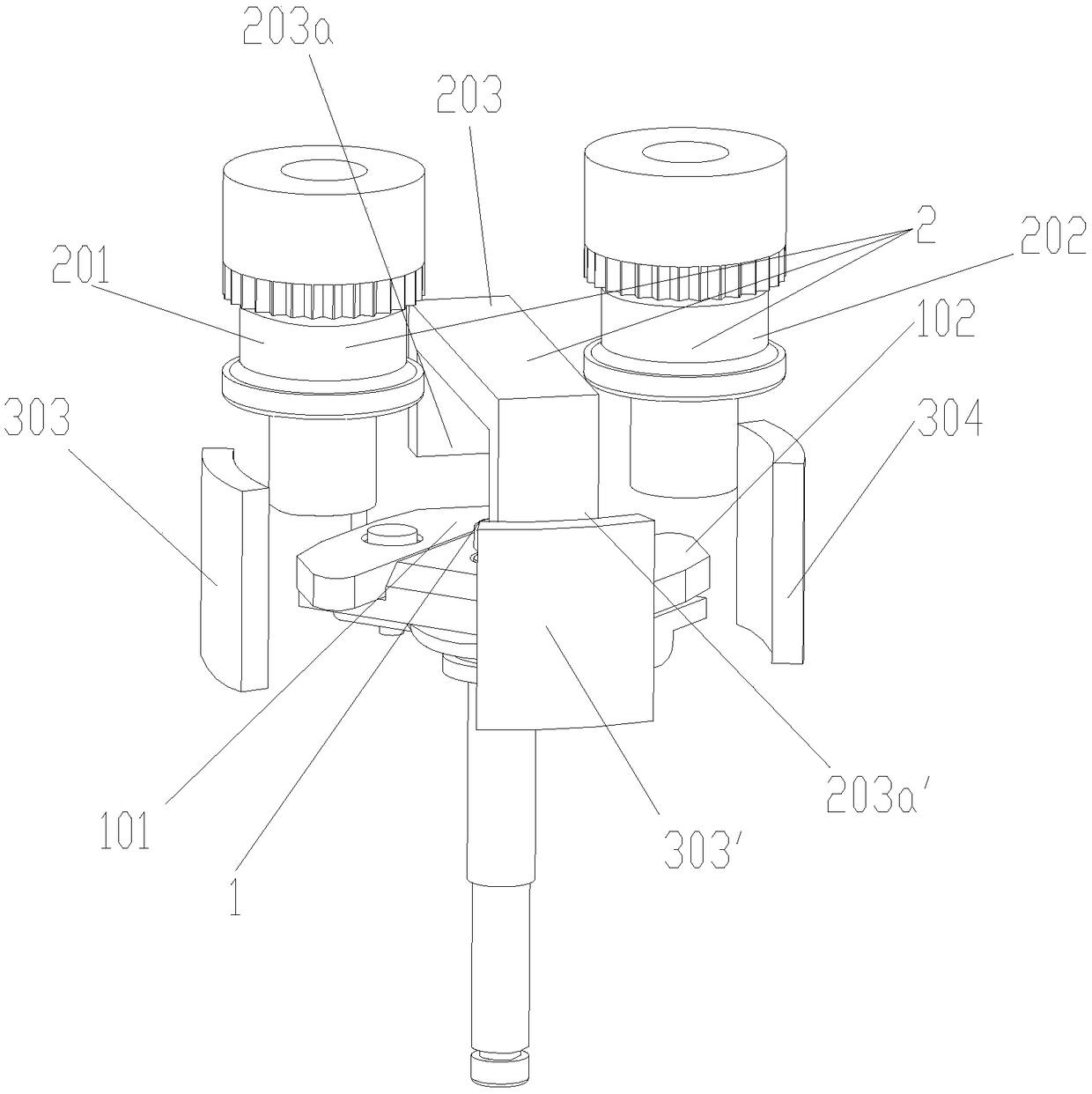

[0021] as attached figure 1 As shown, an embodiment provided by the present invention is a DC contactor arc extinguishing structure, which includes a moving contact assembly 1 and a static contact assembly 2, the moving contact assembly 1 and the static contact assembly 2 The engagement and disengagement of the DC contactor can control the on-off of the DC contactor. The moving contact assembly 1 includes moving contact one 101 and moving contact two 102, the static contact assembly 2 includes static contact one 201, static contact two 202 and static contact three 203, the static contact Head 1 201 and static contact 2 202 correspond to the moving contacts on one of the diagonal lines at both ends of the moving contact 101 and moving contact 2 102 respectively, and the two moving contacts of the moving contact 3 203 The static contacts 203a, 203a' are respectively connected in series with the movable contacts at the other two ends of the diagonal lines at the two ends of the ...

Embodiment 2

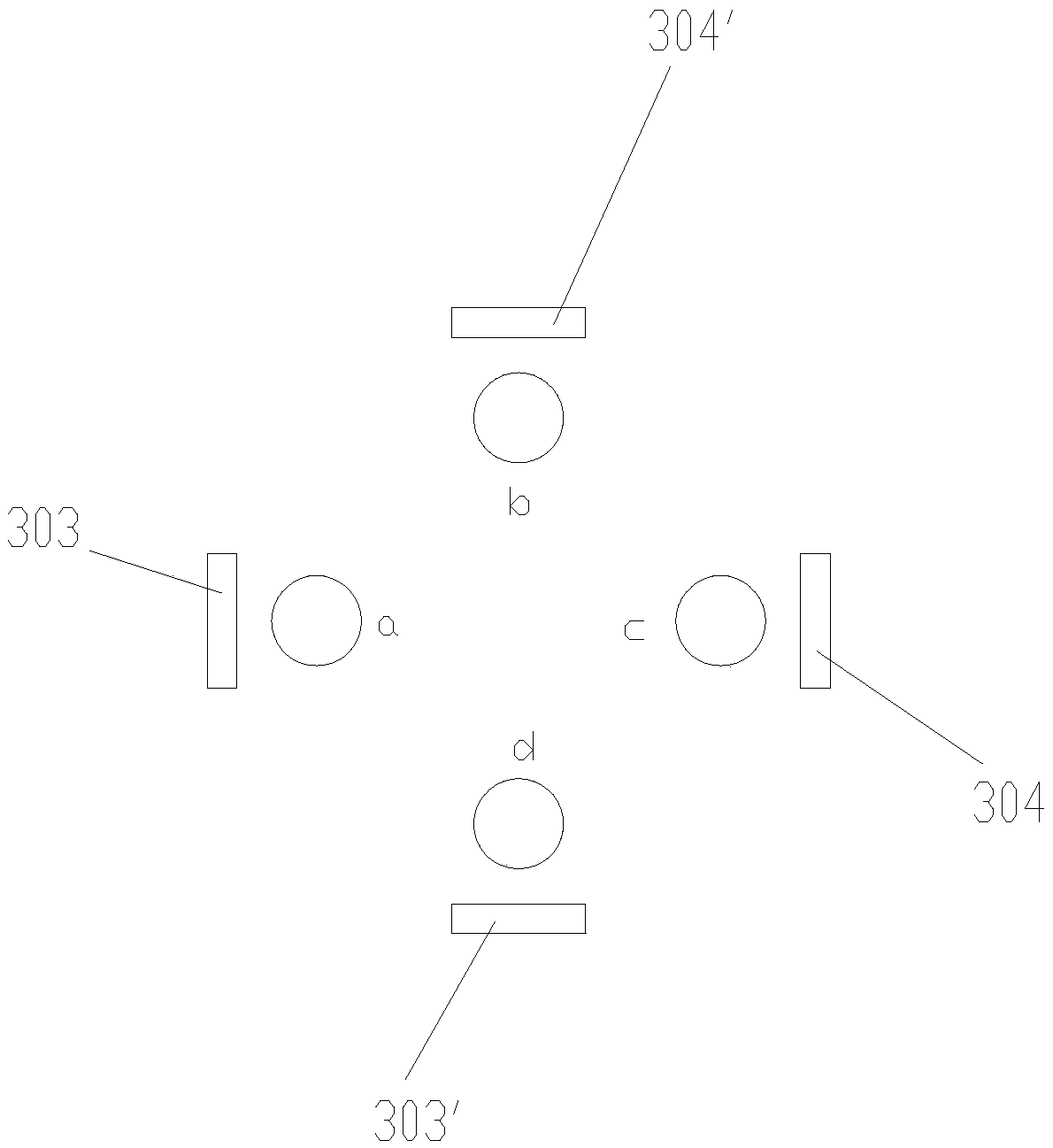

[0026] as attached image 3 As shown, the present invention also provides an embodiment in which the third permanent magnet 303, 303' and the fourth permanent magnet 304, 304' can also be square, and other structures are the same as in the first embodiment.

Embodiment 3

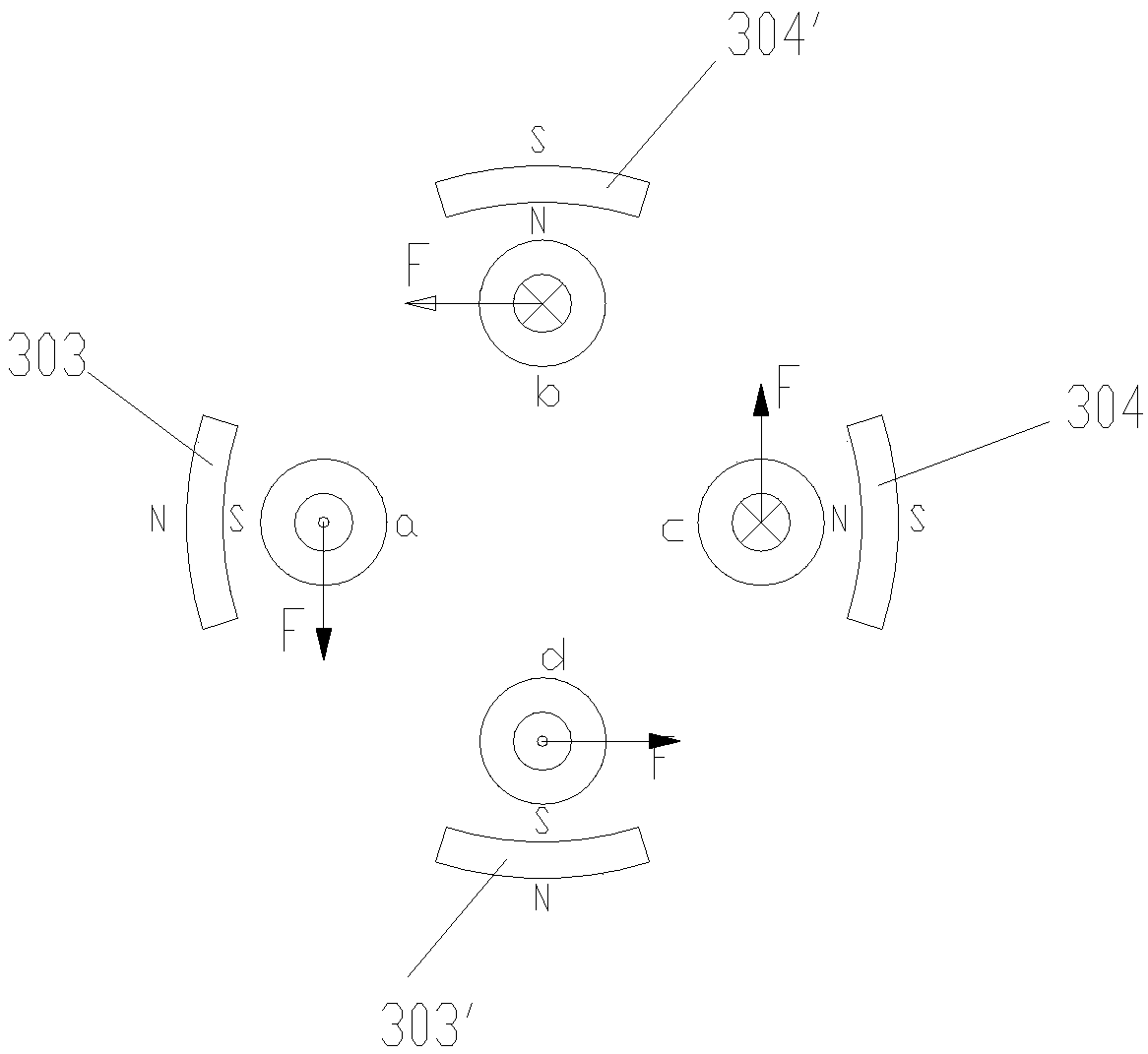

[0028] as attached Figure 4 As shown, in an embodiment provided by the present invention, the four fractures a, b, c, d are sequentially connected end to end to form two permanent magnets on the outside of the area, the moving contact assembly 1 and the static When the contact assembly 2 is engaged, the permanent magnets on the outside of the fracture in the same current direction have the same magnetic pole direction on the fracture surface side, and the magnetic pole directions on the fracture surface side of the permanent magnets on the outside of the fracture in different current directions are different.

[0029] The four fractures a, b, c, d are connected end to end to form two permanent magnets on the outside of the area, the N pole to the S pole of the permanent magnets are from the inside to the outside, and the two permanent magnets are permanent magnets The first 301 and the second permanent magnet 302, the first permanent magnet 301 and the second permanent magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com