Universal Circuit Breaker Panel Contact System

A technology of circuit breaker board and contact system, which is applied to circuit breaker contacts, circuit breaker parts, etc., can solve the problems of short electrical life, low current withstand capacity, and low breaking capacity of contacts, and improve the reliability of action. high performance, high space utilization, and improved current-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

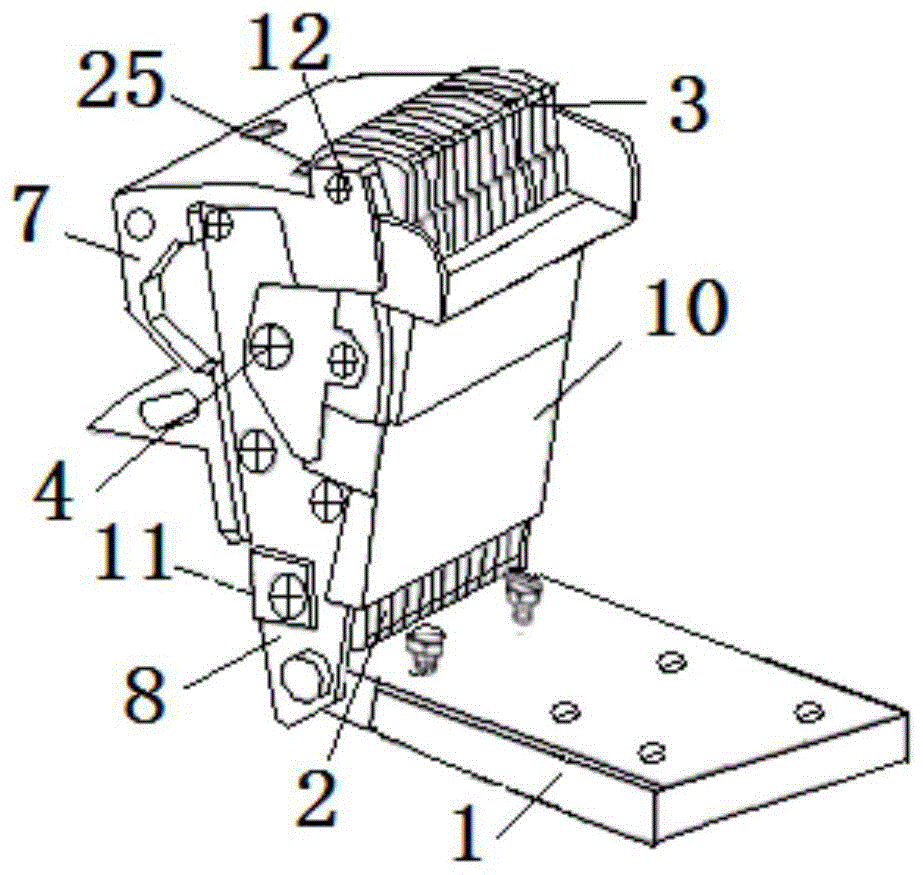

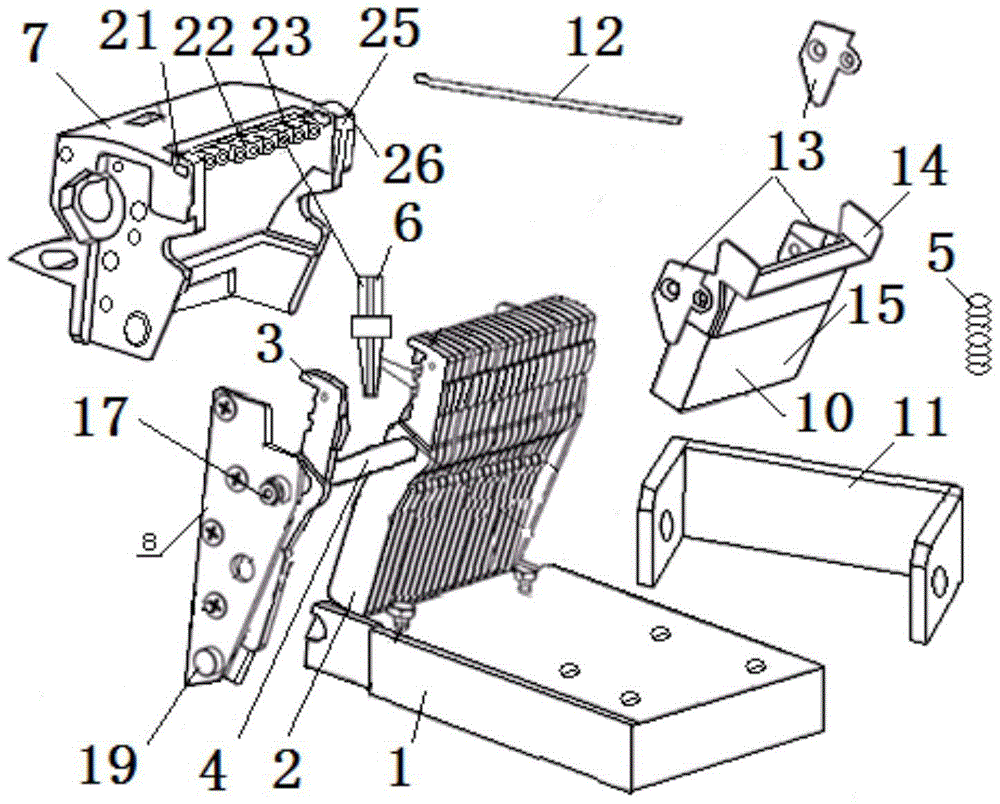

Image

Examples

Embodiment 1

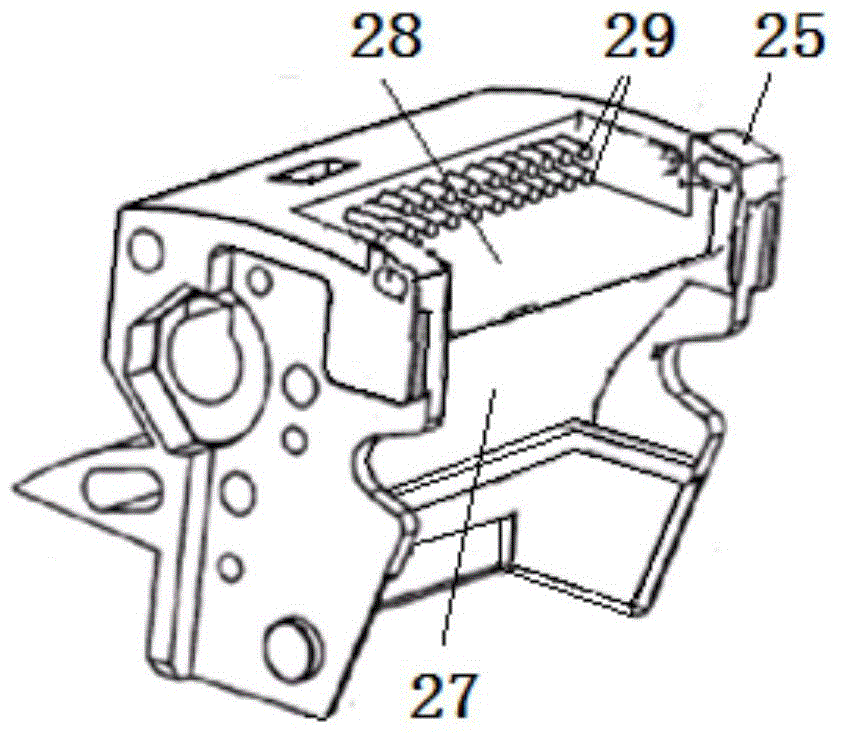

[0064] The insulating expansion plug 6 of Embodiment 1 is used for insulation, heat insulation, positioning, and carrying double springs (ie, the outer spring 40 and the inner spring 42), and the upper stepped cylindrical cylinder 50 and cylinder 51 are used for the inner spring 42 and the outer spring respectively. 40 limit (anti-shaking), and after the insulating expansion bolt 6 is heated and expanded, the gap becomes smaller, preventing the two springs from being bitten to death by the insulating expansion bolt 6;

[0065] see Figure 9 The structure of Embodiment 2 of the insulating expansion plug 6 is that it includes a tapered cylinder 55 that is plugged and fitted with the tapered hole 63 of the contact piece 3, and a lower narrow straight groove 54 is opened in the axial direction on the circumference of the tapered cylinder 55; The tapered cylinder 55 is connected to the cylinder 51 through the intermediate body 53, and the circumference of the cylinder 51 is also pr...

Embodiment 2

[0066] The insulating expansion bolt 6 of embodiment 2 is used for insulation, heat insulation, positioning, and carrying a single spring. The upper narrow straight groove 52 is used for limiting (anti-shaking) to the spring 5. After the insulating expansion bolt 6 is heated and expanded, the gap becomes larger. Small, to prevent the spring 5 and the insulating expansion bolt 6 from being seized.

[0067] refer to Figure 10 , is another structural form of the busbar 1, called the busbar 29, the rear end of the busbar 29 is a cylinder, and the front end of the busbar 29 is a plate shape.

[0068] The working principle of the present invention is,

[0069]The opening groove 60 of the contact piece 3 removes the middle connecting plate part of the existing structure, and directly overlaps with the lower mounting hole 63, which shortens the distance and reduces the weight and increases the compensation effect of the short-circuit current electromotive force; the upper welding jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com