Contact support structure for air circuit breaker contact system

A technology of contact support and contact system, applied in the direction of circuit breaker contacts, circuit breaker components, etc., can solve the problem of burning of one-way contact blades, impossibly thin thickness, and contact system loops The number of problems is small, and the effect of high space utilization, improved operation reliability, and convenient assembly and positioning is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

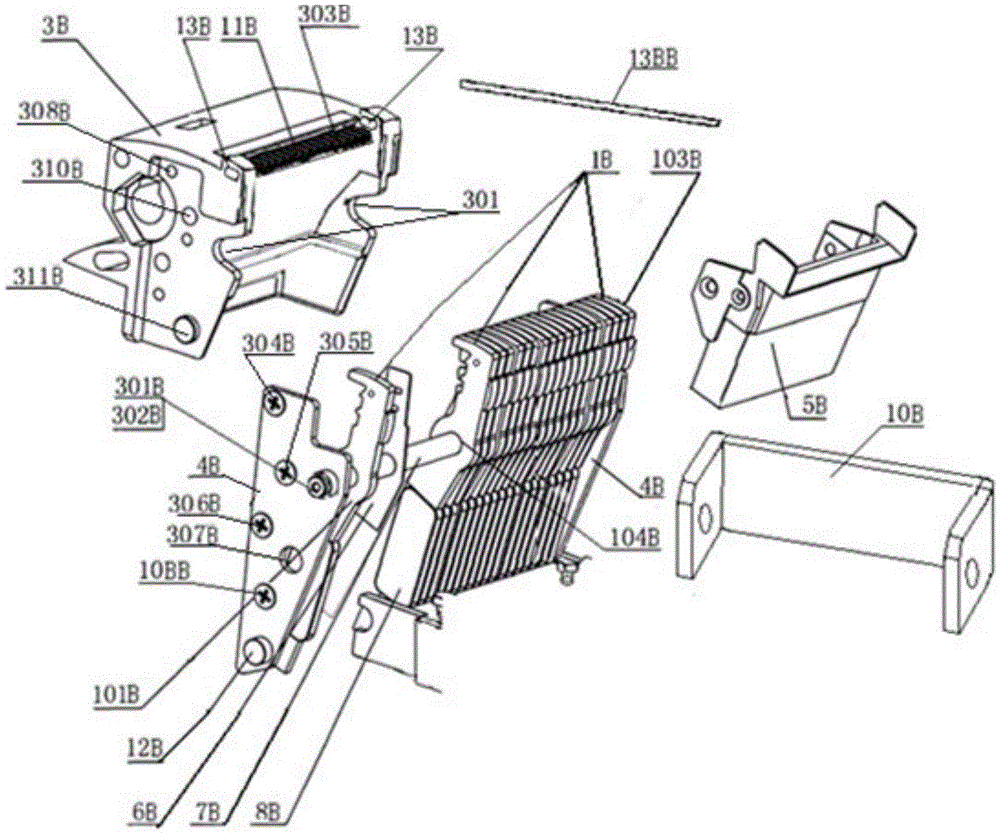

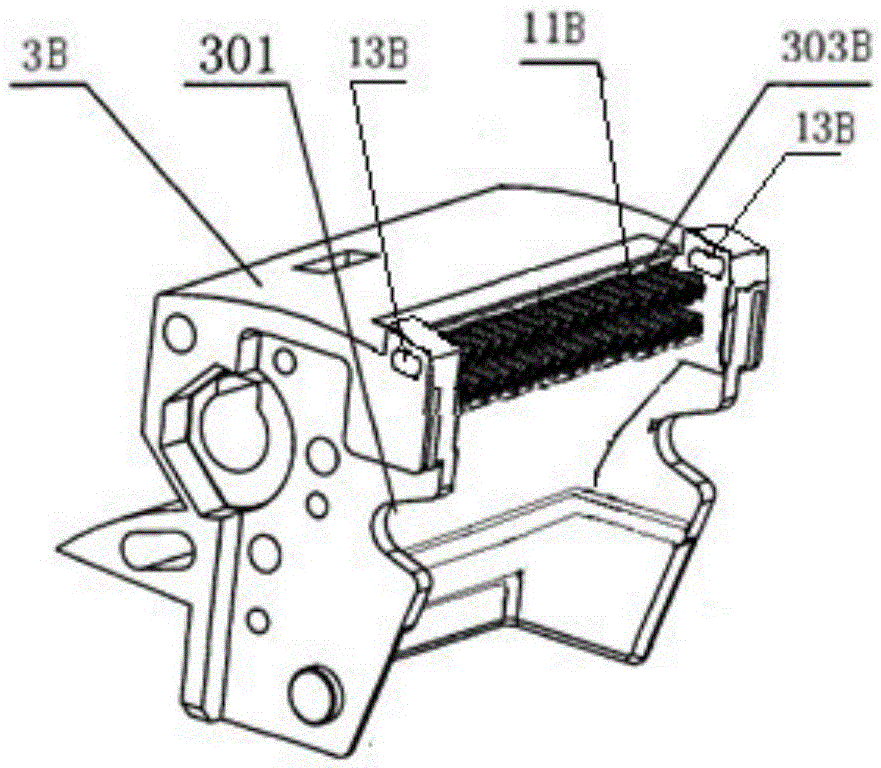

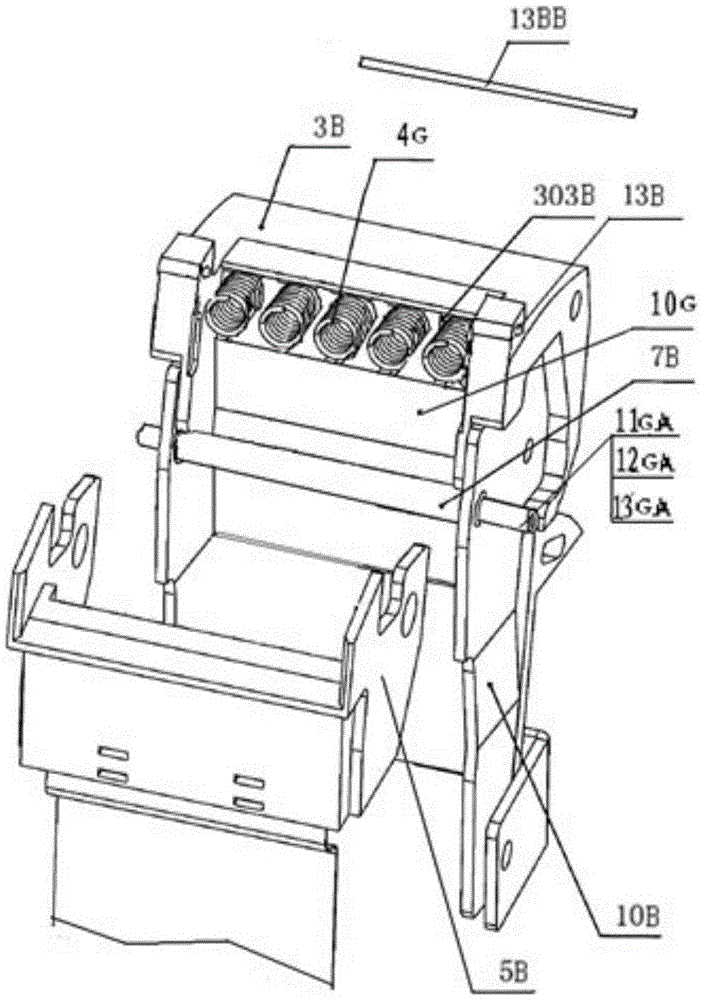

[0033] see figure 1 , figure 2 , a contact support structure of a universal circuit breaker contact system, including a contact support body 3B and a movable insulating partition assembly 6B, the movable insulating partition assembly 6B is spaced from the moving contact piece 101B to maintain the moving contact The main contact surface of the head piece 101B is parallel to the axis of the intermediate rotary support shaft 7B as much as possible, so that multiple moving contact pieces 101B are isolated into independent conductive circuits; two spaced moving contact pieces 101B form adjacent contacts. The head piece 1B; the adjacent contact piece 1B is connected with a soft connection 8B, which constitutes the contact conductive system of the present invention; the movable insulating partition assembly 6B and the adjacent contact piece 1B are provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com