Supported catalyst, and preparation method and application thereof

A supported catalyst and carrier technology, applied in the chemical field, can solve the problems of strong material corrosion, complicated process and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

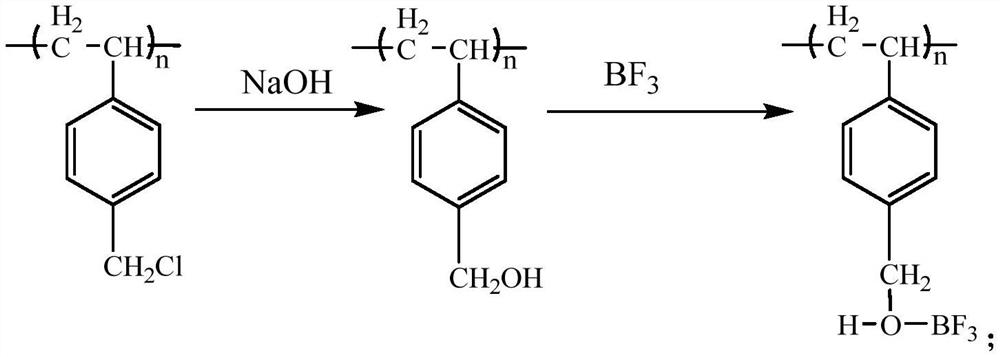

[0077] This embodiment provides a supported catalyst, including a carrier and an active component supported on the surface of the carrier, wherein the carrier is methylol polystyrene, and the active component is boron trifluoride.

[0078] Among them, the preparation method of the supported catalyst includes: adding 100mL of chloromethylated polystyrene (purchased from Aladdin, product number C110262) to a volume of 200mL and a concentration of 10% sodium hydroxide aqueous solution, stirring and reacting at 60°C for 5h , filtered, washed with 200mL deionized water, dried at 120°C for 24h, transferred to a three-necked flask, turned on mechanical stirring, under the protection of nitrogen, introduced boron trifluoride gas, reacted at 20°C for 5h, and obtained supported boron trifluoride catalyst.

Embodiment 2

[0080] The only difference from Example 1 is that the reaction temperature of chloromethylated polystyrene and sodium hydroxide solution is 90°C.

Embodiment 3

[0082] The only difference from Example 1 is that the reaction temperature of chloromethylated polystyrene and sodium hydroxide solution is 110°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com