Pixel defining layer and manufacturing method, display substrate and manufacturing method, display panel

A pixel-defining layer and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems affecting the uniformity of solution film formation, avoid light leakage and cross color, and improve film formation uniformity. , the effect of reducing the degree of climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

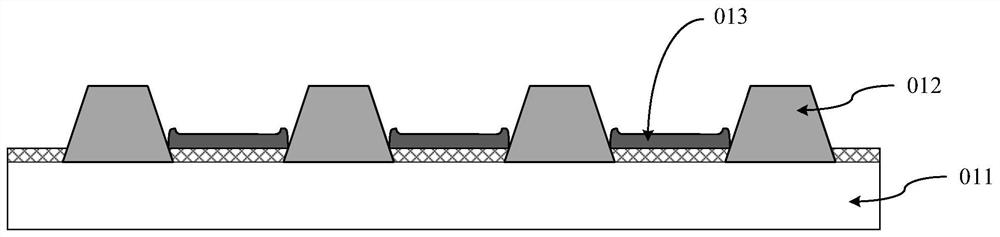

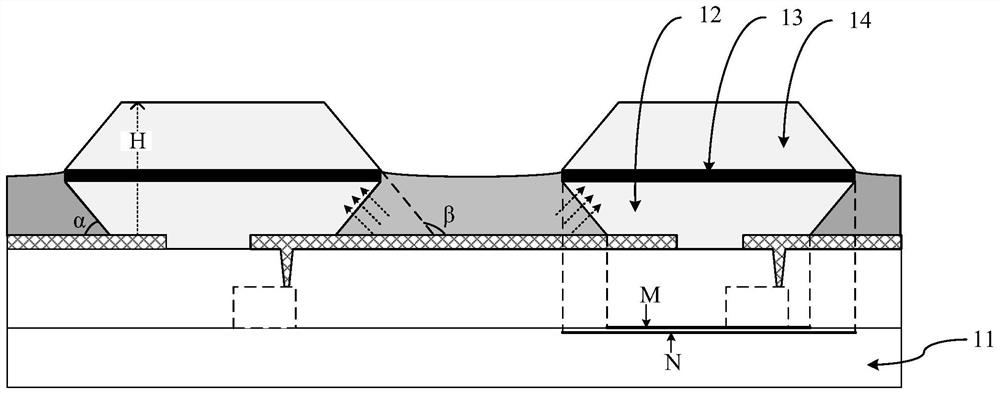

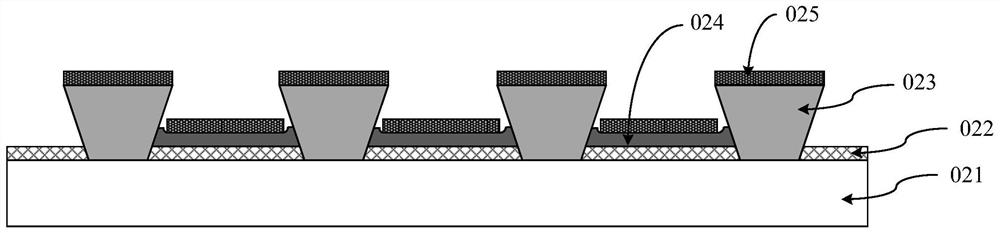

[0057] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0058] With the development of display panels towards thinner, lower power consumption and portability, a new generation of display technology represented by OLED display panels has attracted more and more attention. Compared with liquid crystal display panels, OLED display panels have the advantages of thinner and lighter, low power consumption, low driving voltage, better viewing angle, contrast ratio, and faster response speed. The film-forming methods of the organic light-emitting layer of the OLED display panel mainly include evaporation process and solution process. The evaporation process is relatively mature in small-scale applications, and this technology has been applied in mass production. The solution process mainly includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com