Waste car lamp breaking device

A technology for processing devices and car lights, applied in the field of machinery and equipment, can solve problems such as low work efficiency, incomplete crushing, and complicated operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

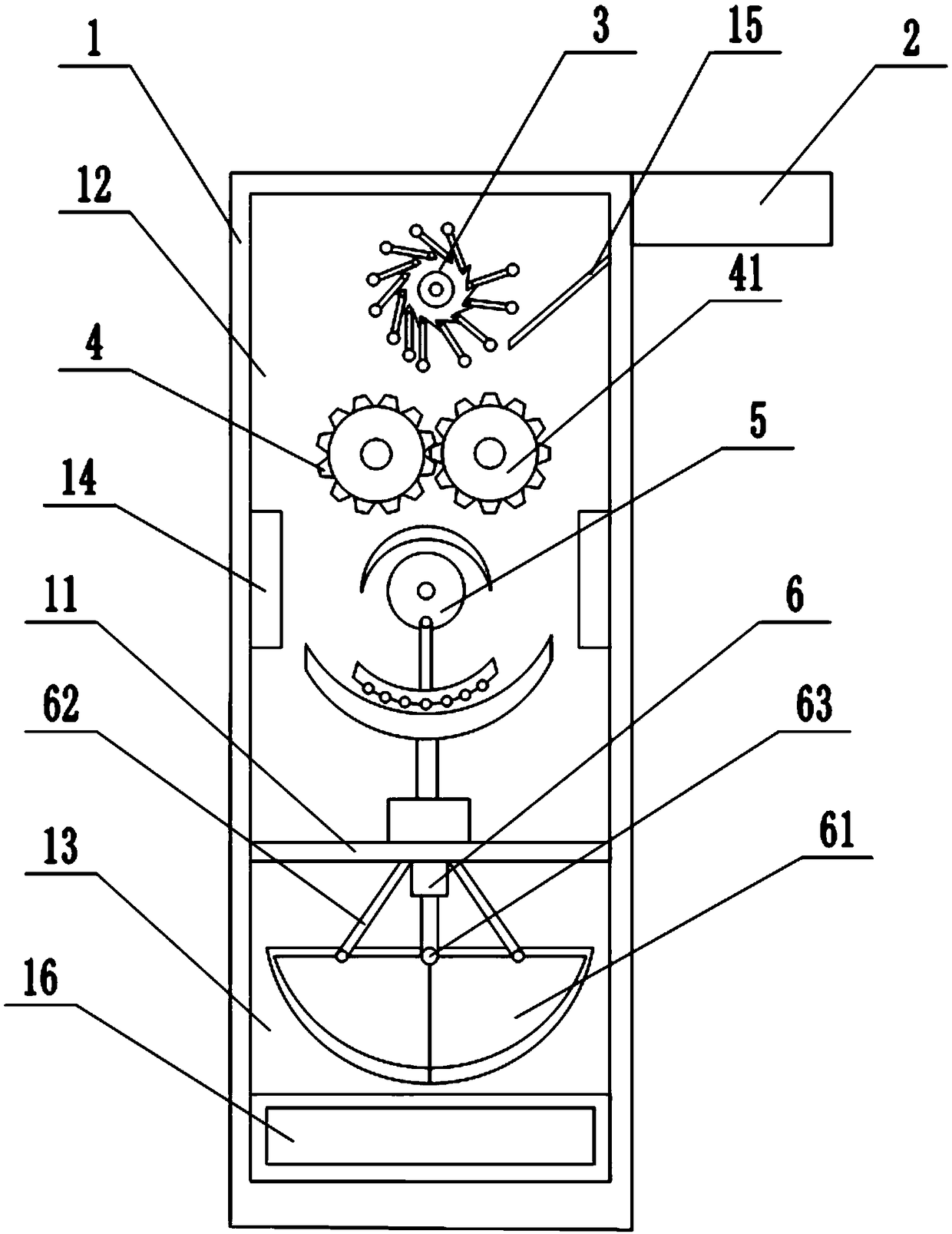

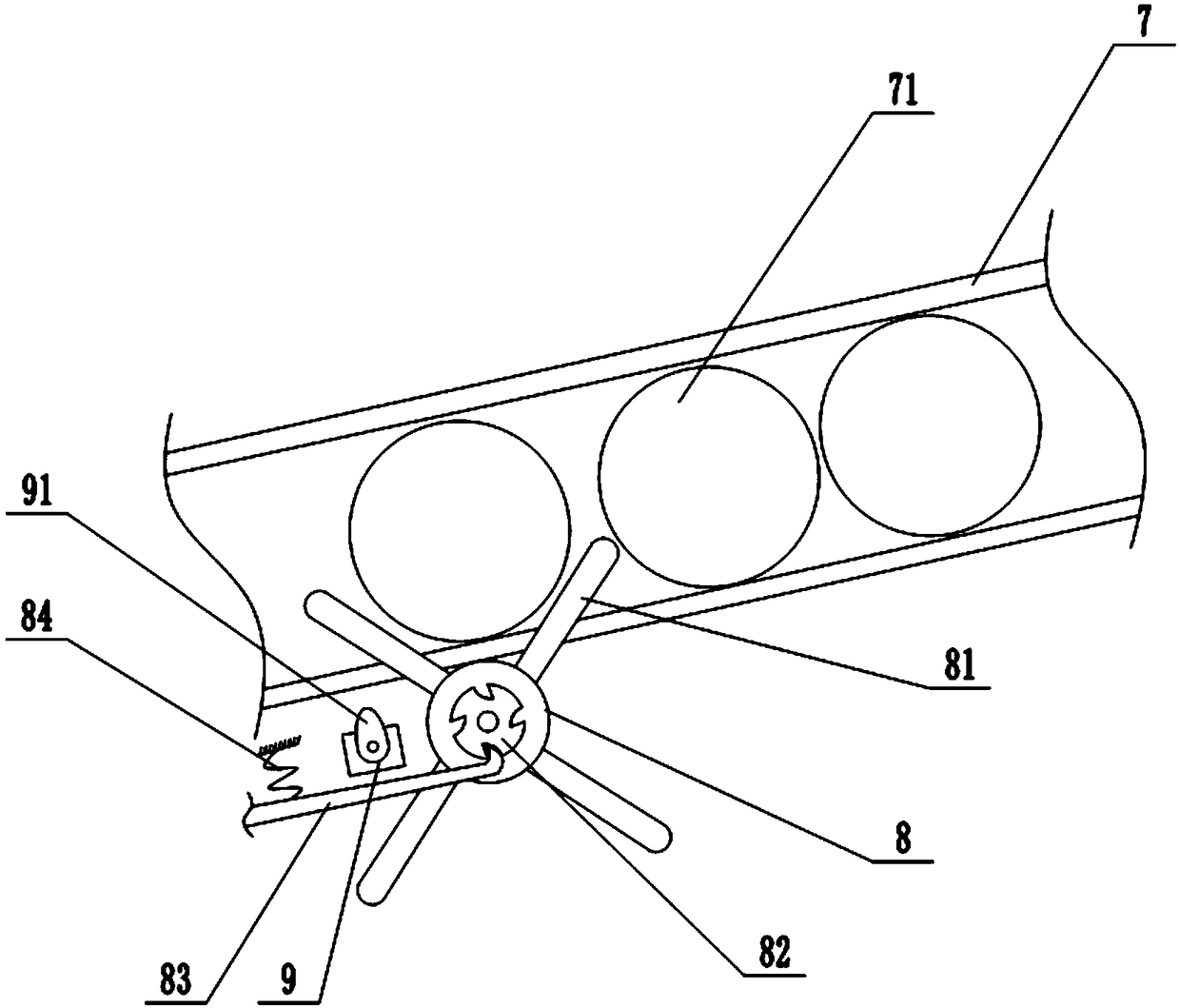

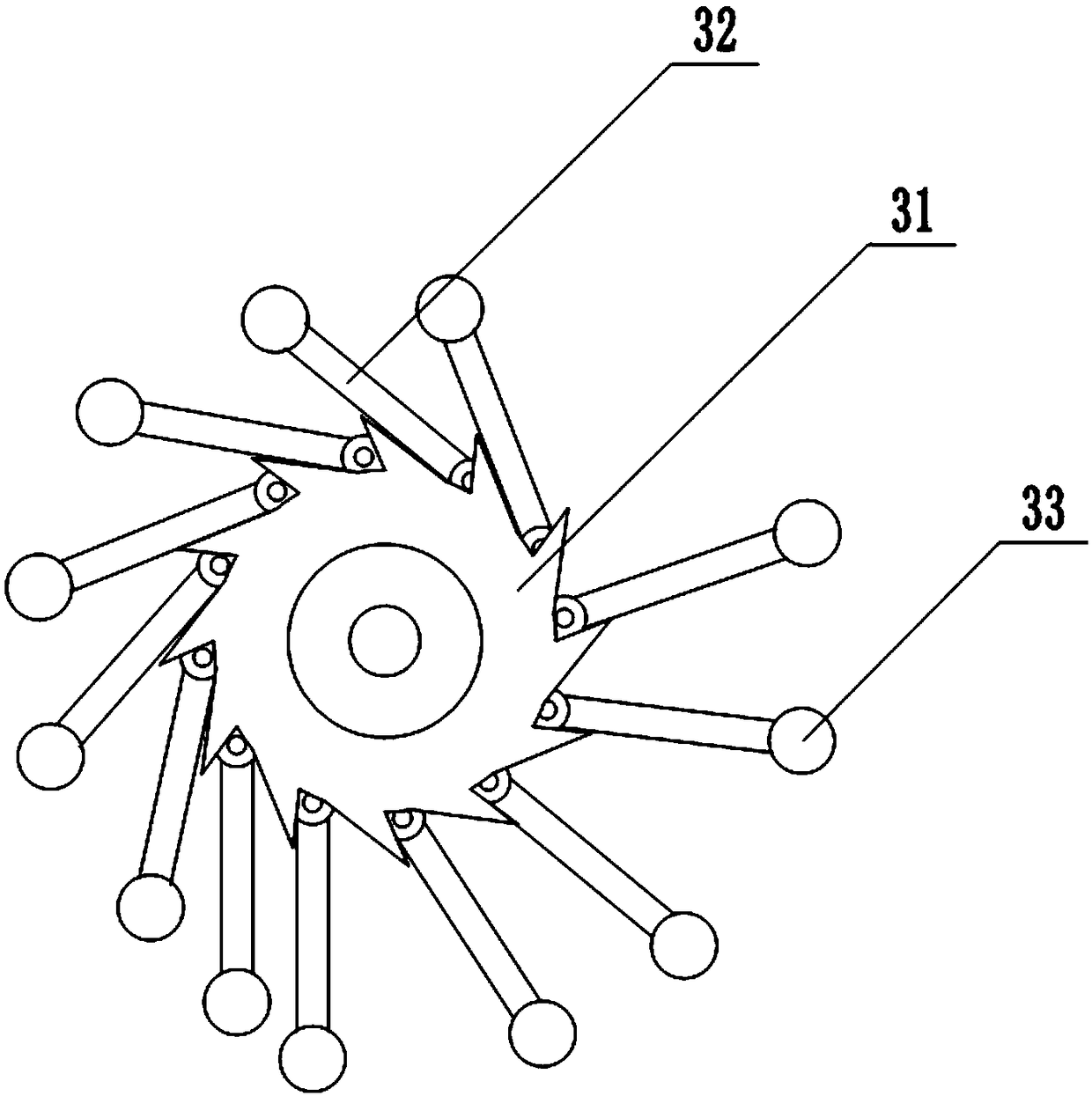

[0019] The reference signs in the drawings of the description include: crushing box 1, partition 11, processing chamber 12, collecting chamber 13, electrostatic plate 14, guide plate 15, collecting box 16, feeding box 2, beating mechanism 3, first ratchet 31. Swing bar 32, hammering ball 33, crushing tooth 4, rotating roller 41, crushing mechanism 5, first rotating disk 51, arc-shaped material guide plate 52, hinged rod 53, arc-shaped pressing plate 54, rolling ball 55, the first Three motors 56, arc-shaped grinding plate 57, cylinder 6, hopper 61, support rod 62, cross bar 63, slideway 7, waste car lamp 71, second rotating disc 8, baffle plate 81, second ratchet 82, claw hook 83, extension spring 84, the 4th motor 9, cam 91.

[0020] The embodiment is basically as attached Figures 1 to 4 Shown: a waste car lamp crushing processing device, including a crushing box 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com