spray gun

A technology of spray guns and nozzles, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of single adjustment function, inconvenient operation and use, and limitations, and achieve the effects of convenient switching and adjustment, simple structure, and easy assembly and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Based on the above technical features, the main functions of the spray gun of the present invention will be clearly presented in the following embodiments.

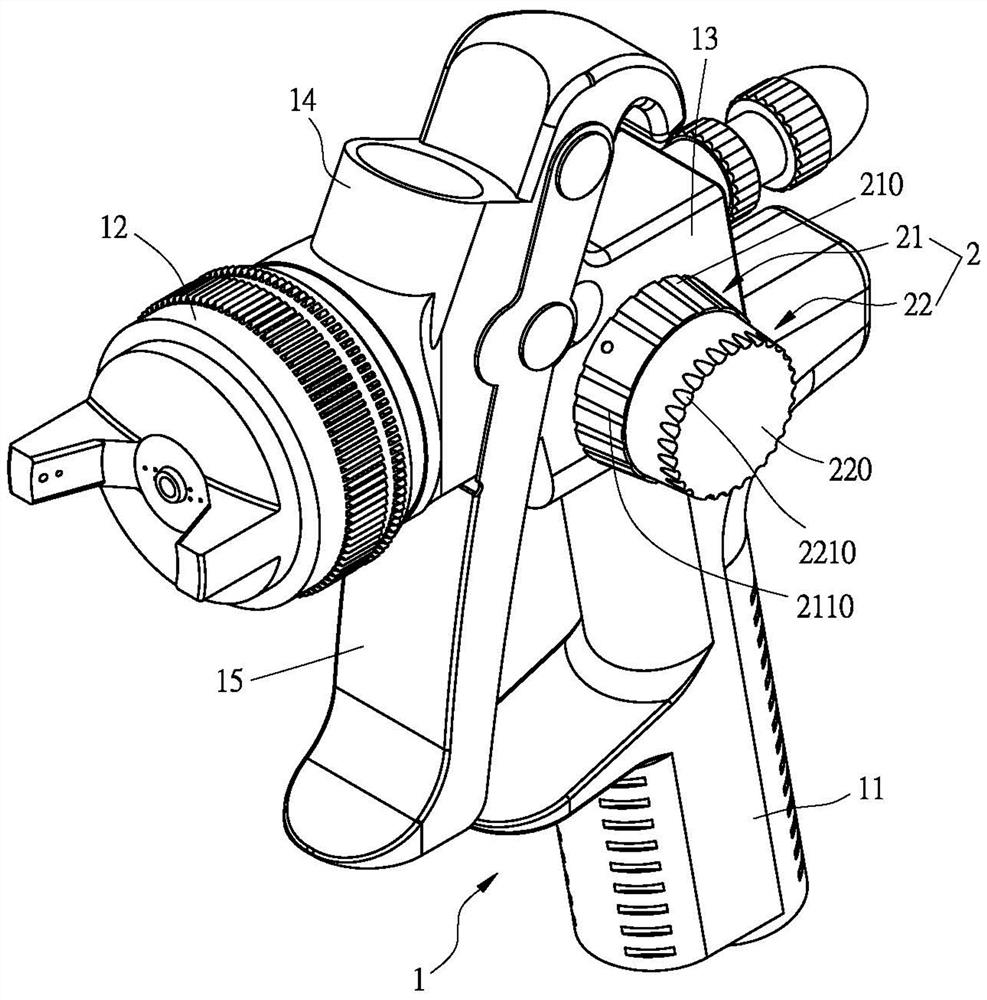

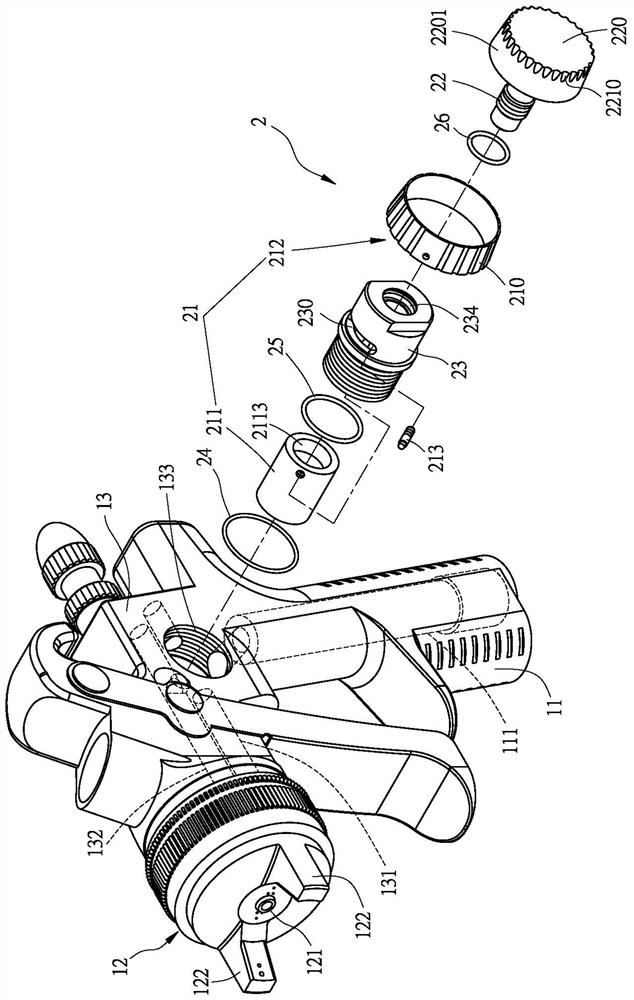

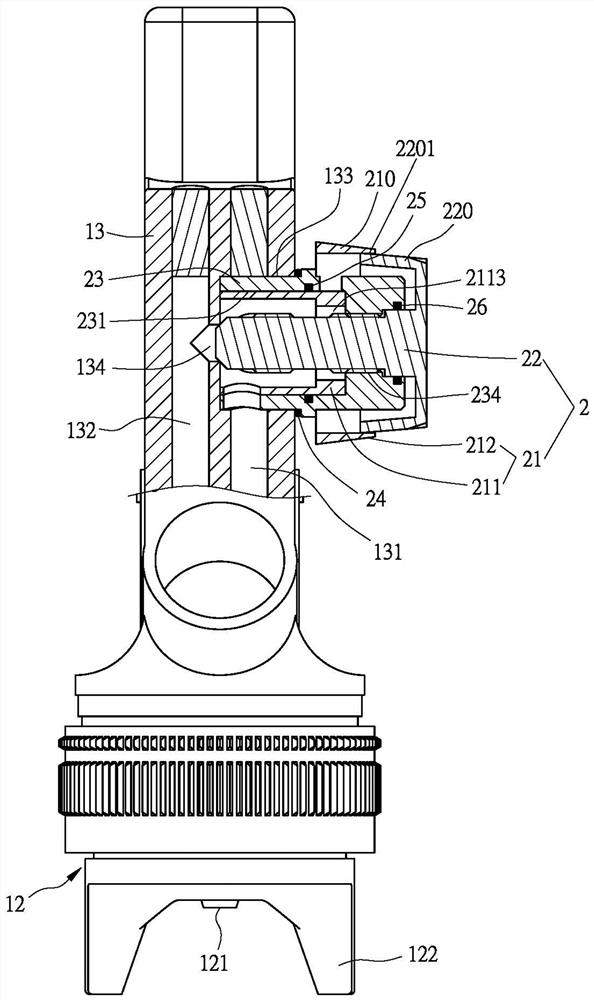

[0056] Please see first figure 1 , discloses the spray gun of the embodiment of the present invention, including a spray gun body 1 and a regulating valve 2 installed on the spray gun body 1 . The spray gun body 1 includes a handle portion 11 , a spray head 12 , and a body portion 13 connecting the handle portion 11 and the spray head 12 . The adjusting valve 2 is located on the body 13 adjacent to the gripping portion 11 , so that the user can use the thumb to operate it conveniently.

[0057] see again figure 1 , in this embodiment, the spray gun body 1 is mainly used for painting, so it may further include a paint supply part 14, and the paint supply part 14 is used for connecting a paint tank, for example. Therefore, when a trigger 15 of the spray gun body 1 is pressed and displaced to a predetermined positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com