Automatic bolt feeding device

An automatic feeding and automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as low efficiency and poor accuracy, and achieve the effects of simple control, short clamping action time, and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention provides automatic bolt feeding equipment. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

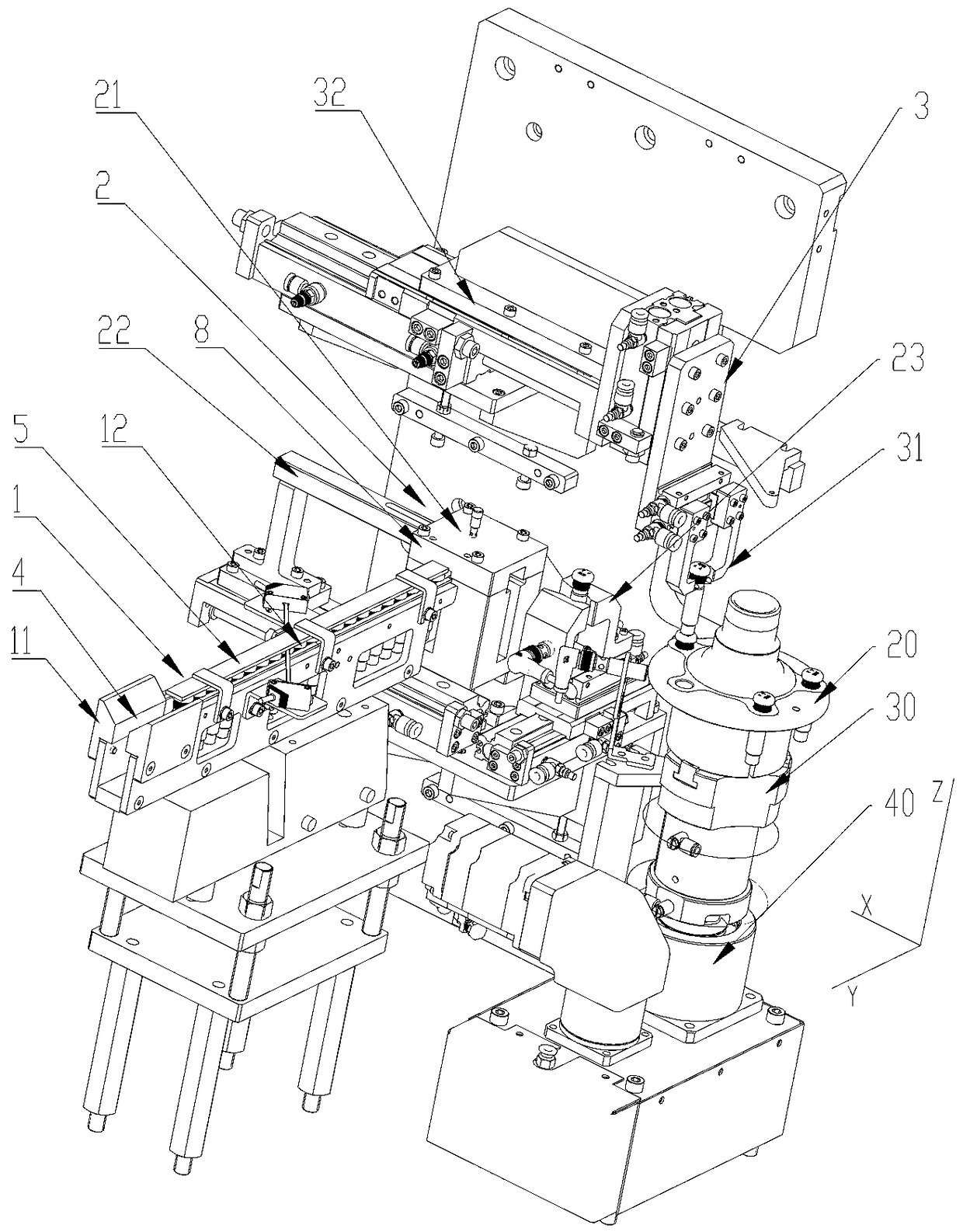

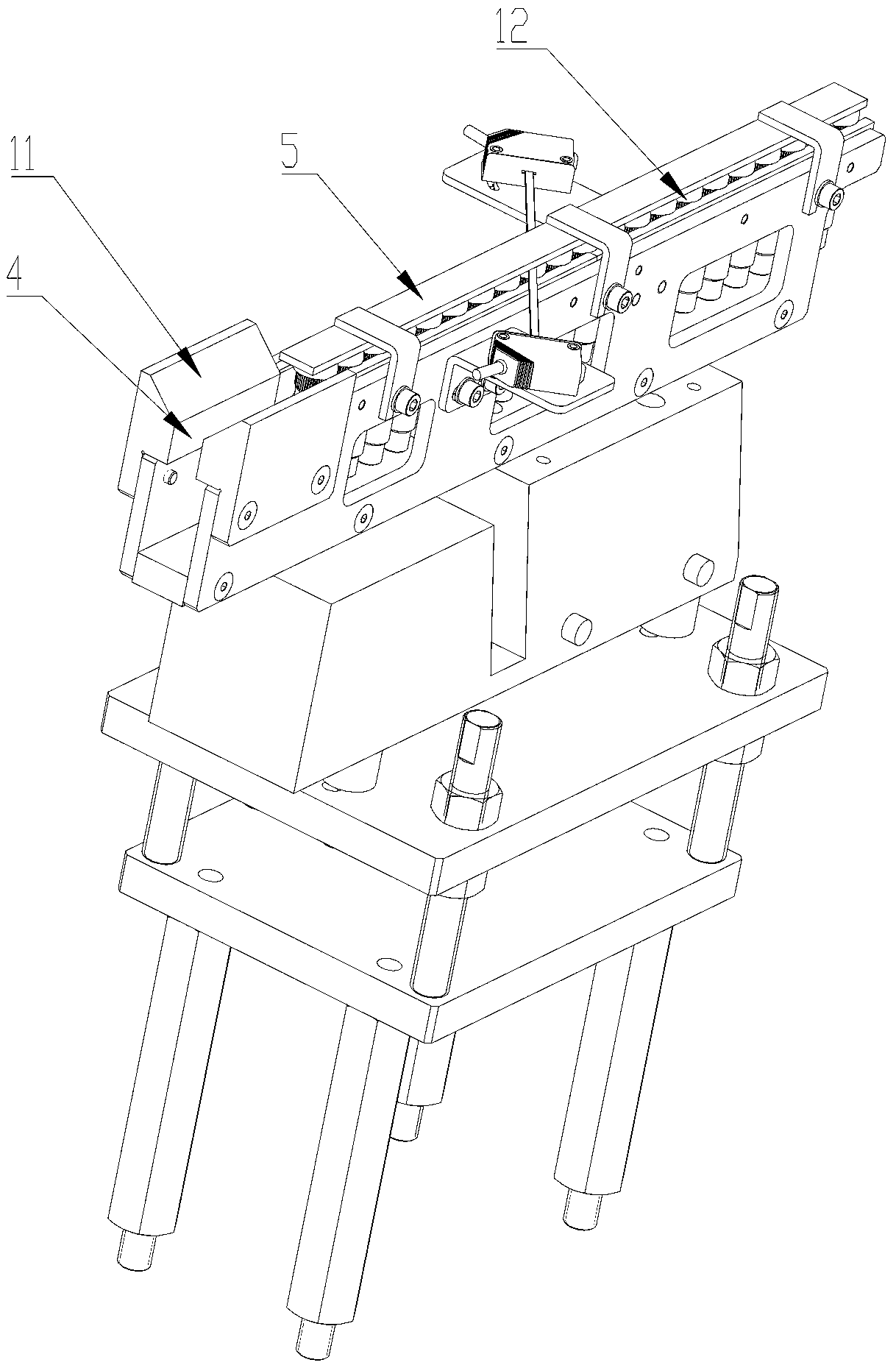

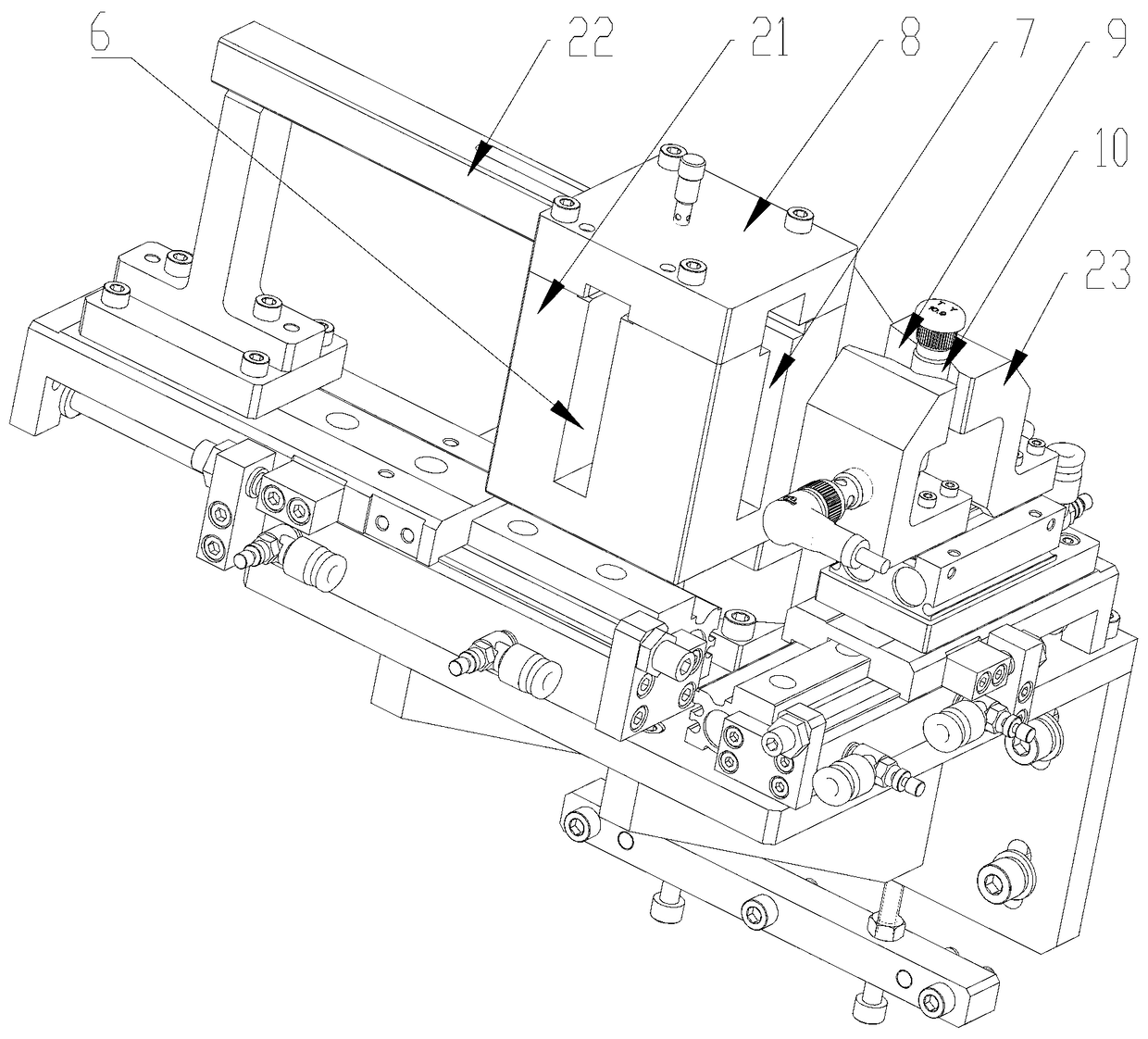

[0034] Automatic bolt feeding equipment, used for automatic feeding of bolts into the equipment, such as Figure 1 to Figure 4 As shown, it includes the whole row module 1 for automatic loading and whole row export of bolts, the bolt export module 2 for clamping and exporting the output bolts of whole row module 1, and the bolt export module 2 for bolt export Clamp and load the clamping and loading module 3 in the bolt pressing equipment.

[0035] Specifically, the alignment module 1 includes an introduction end 11 connected to the external vibrating plate, and an alignment passage 12 connected to the introduction end 11; the bolt export module 2 includes a bearing seat 21 connected to the alignment passage 12, for connecting the carria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com