A cleaning method for cleaning track plate mold rail bearing shell

A cleaning method and track plate technology, which are used in manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., to achieve the effect of reducing production costs, satisfying high-efficiency production characteristics, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to avoid obscuring the present invention with unnecessary details, only the device structures and / or processing steps closely related to the solution according to the present invention are shown in the drawings, while other details that are not closely related to the present invention are omitted .

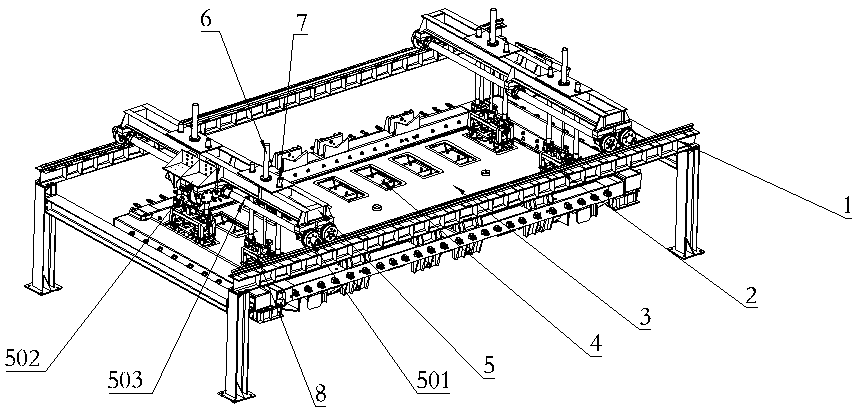

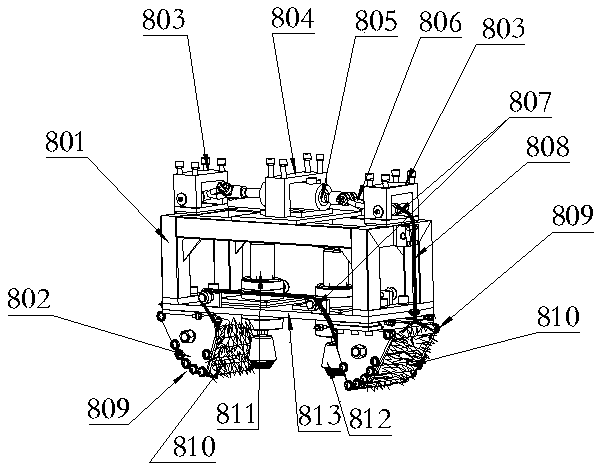

[0012] figure 1 Among them, a device for cleaning the rail bearing shell of a track plate mold, including a base beam 1, a track 2, a walking trolley 5, a lifting cylinder 6, a guide column 7, and a cleaning device 8; the base beam 1 is supported by four bases, two The long side beams are parallel; the two tracks 2 are parallel and are respectively fixed above the long sides of the base beam 1; the walking trolleys 5 are two, and are arranged side by side on the two tracks 2; the walking trolleys 5 are provided with walking wheels 501 , power output mechanism 502, transmission shaft 503. The walking trolley 5 is also provided with a lifting cylinder 6, and a clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com