Track plate production device with distance between execution modules capable of being automatically adjusted along with adjustment of steel bar spacing

An execution module and automatic adjustment technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of uneven spacing of prestressed steel bars, the inability of the production line to adapt to various specifications, and the inability to adapt to steel bars, so as to reduce long pauses. , to meet the high-efficiency production characteristics, the effect of low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

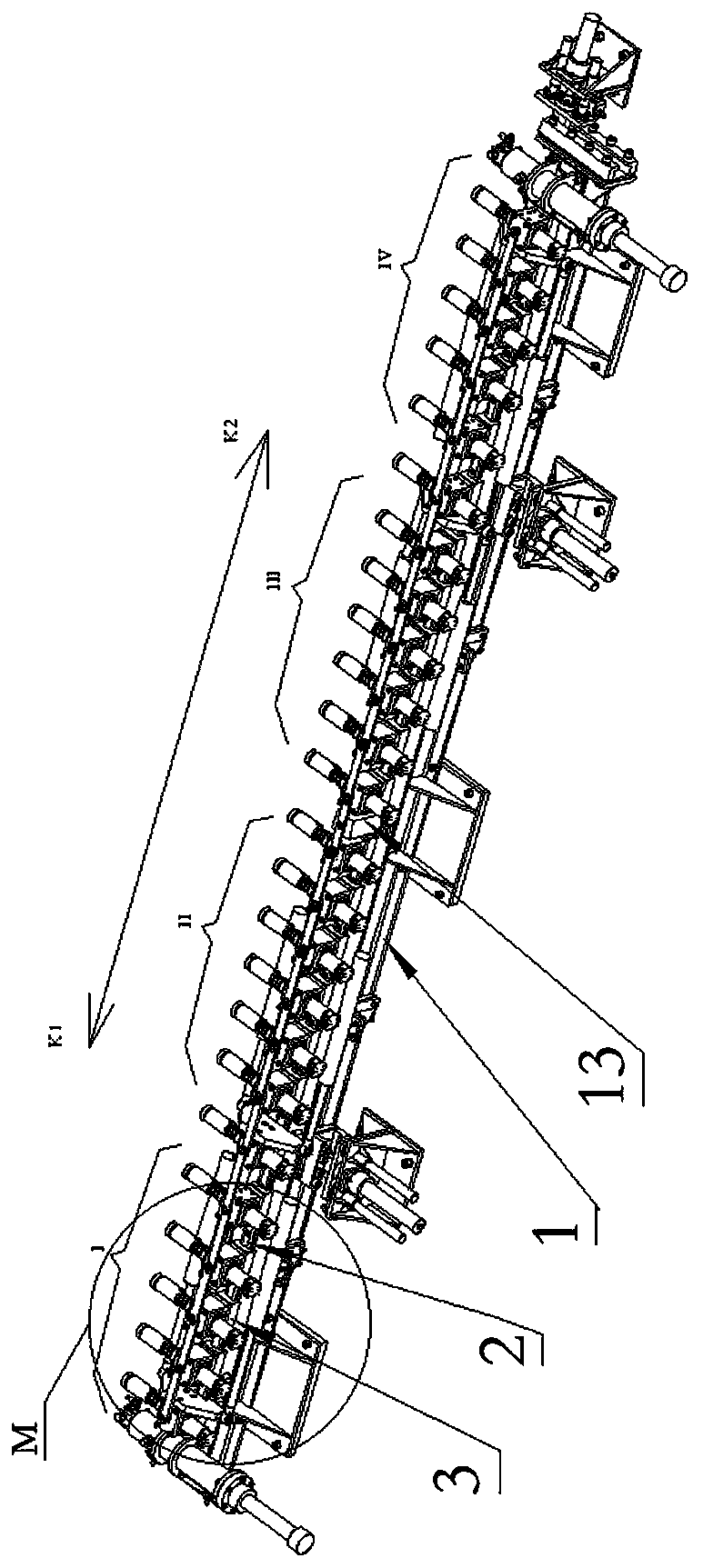

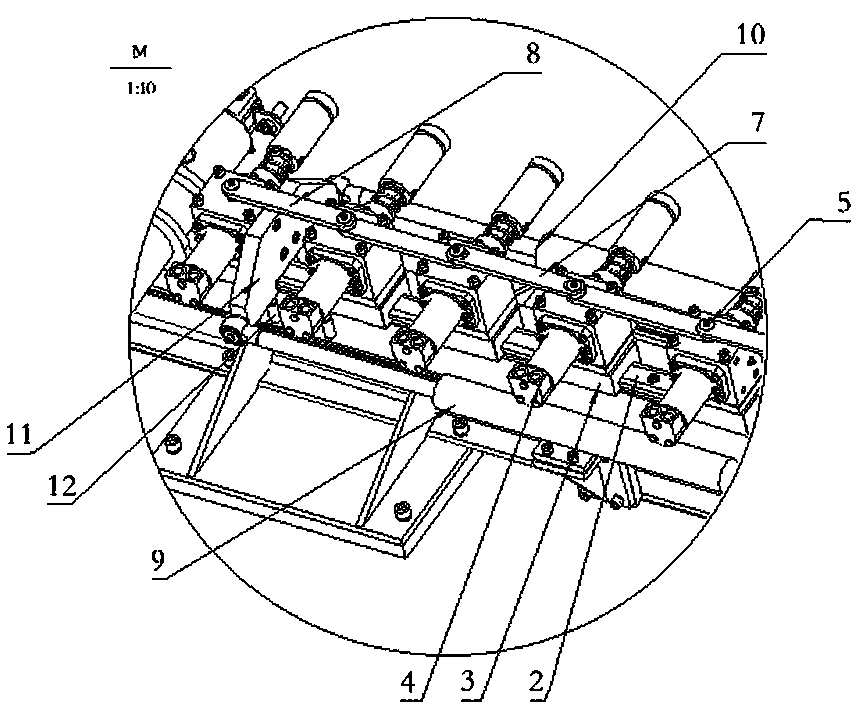

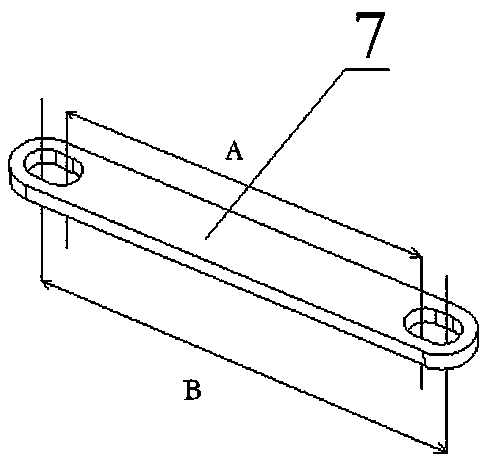

[0019] Figure 1-4 Among them, the track plate production device that can automatically adjust the distance between the execution modules according to the adjustment of the steel bar spacing includes a beam base 1, a linear guide rail 2 is fixed on the base, and several sliders 3 are placed on the linear guide rail. The two are connected by a dovetail groove structure. Adaptation to ensure that it has the characteristics of static stiffness, guiding accuracy, and low-speed motion stability. The execution modules 4 corresponding to the slider 3 are respectively fixed on the slider 3 by screws. The execution modules 4 correspond one-to-one to the prestressed steel bars of the track slab. The first push-pull cylinder 9 and the second push-pull cylinder 10 are symmetrically installed on both sides of the base 1. During operation, a push plate 11 is fixed on the inner side of the end execution module. The first push-pull cylinder 9 and the second push-pull cylinder 10 The rod end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com