Film mulching device for metal inner wall and film mulching method

A coating device and metal technology, applied in the field of metal inner wall coating devices, can solve problems such as difficulties, difficult processes, and inability to guarantee full coverage, etc., and achieve the effects of convenient and quick operation, simple operation, and convenient filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

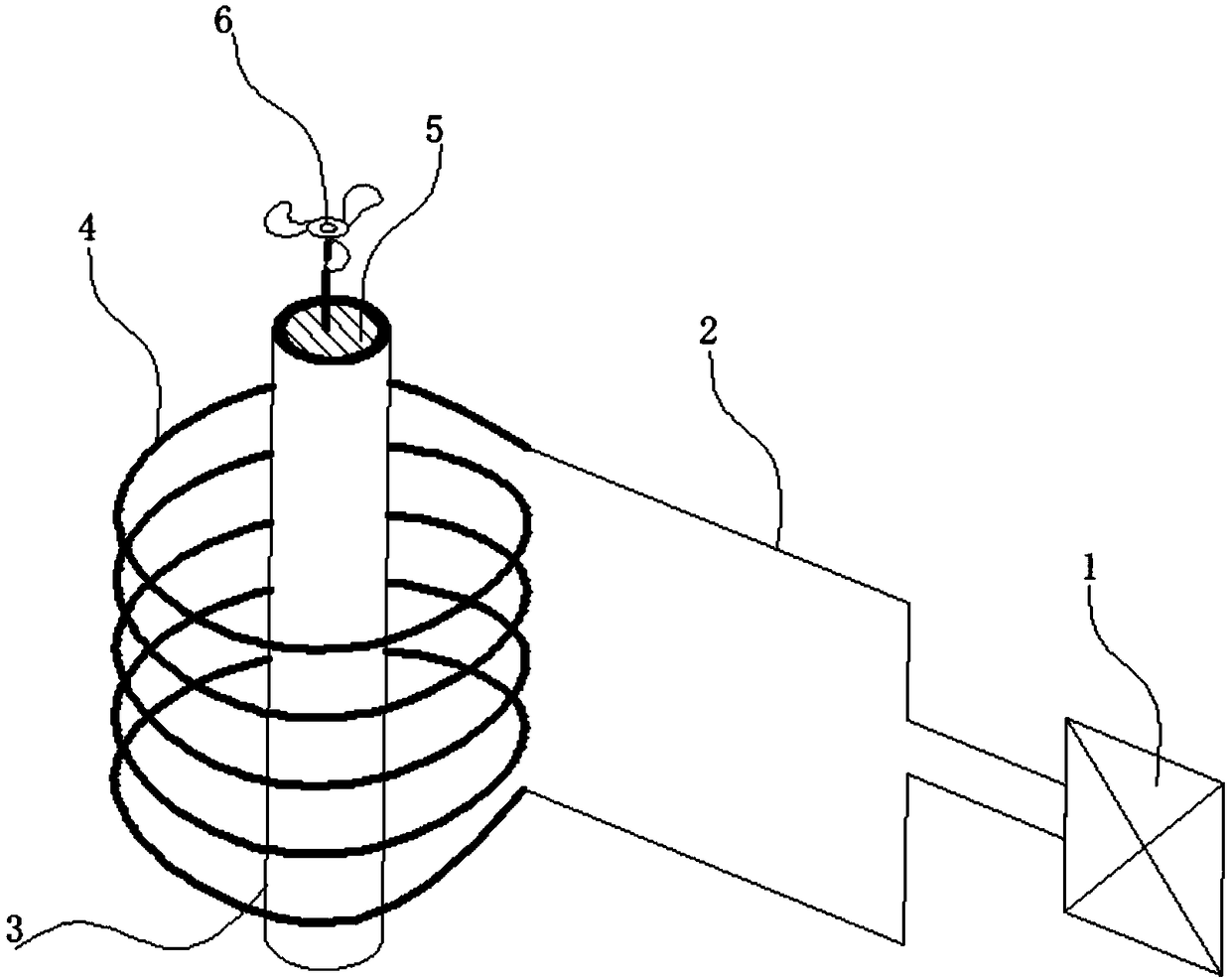

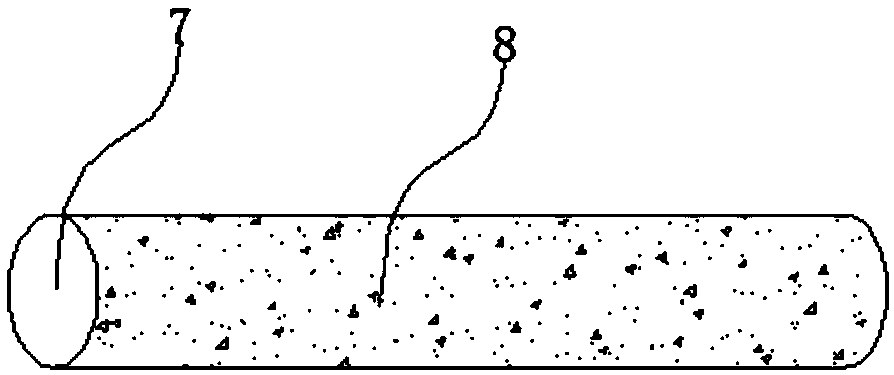

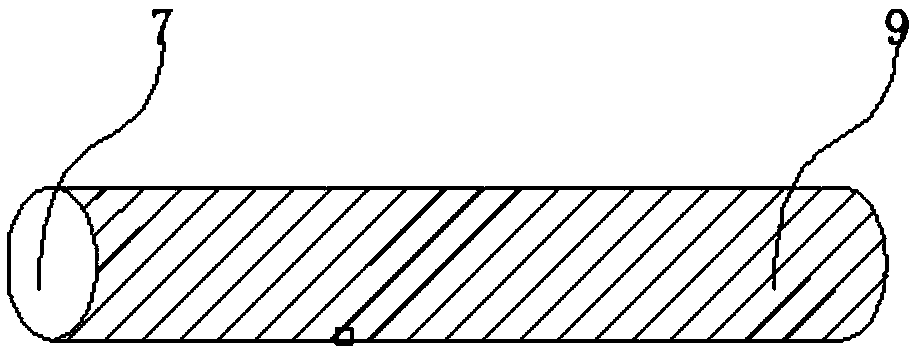

[0031] Such as figure 1 As shown, a metal inner wall coating device includes: a power supply 1, the power supply 1 is an alternating current, a coil 4 electrically connected to the power supply 1 through a wire 2, and a cooling device arranged on one axial or radial side of the coil 4 , and the film and the deformable film module 7 .

[0032] The coil 4 is made of copper material, which has a good conductive effect, and the outer circumference of the coil 4 is wrapped with an insulating material to ensure the safety performance of the device. At the same time, a fan 6 is arranged on one axial side of the device for cooling the metal with coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com