Patents

Literature

36results about How to "Lamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

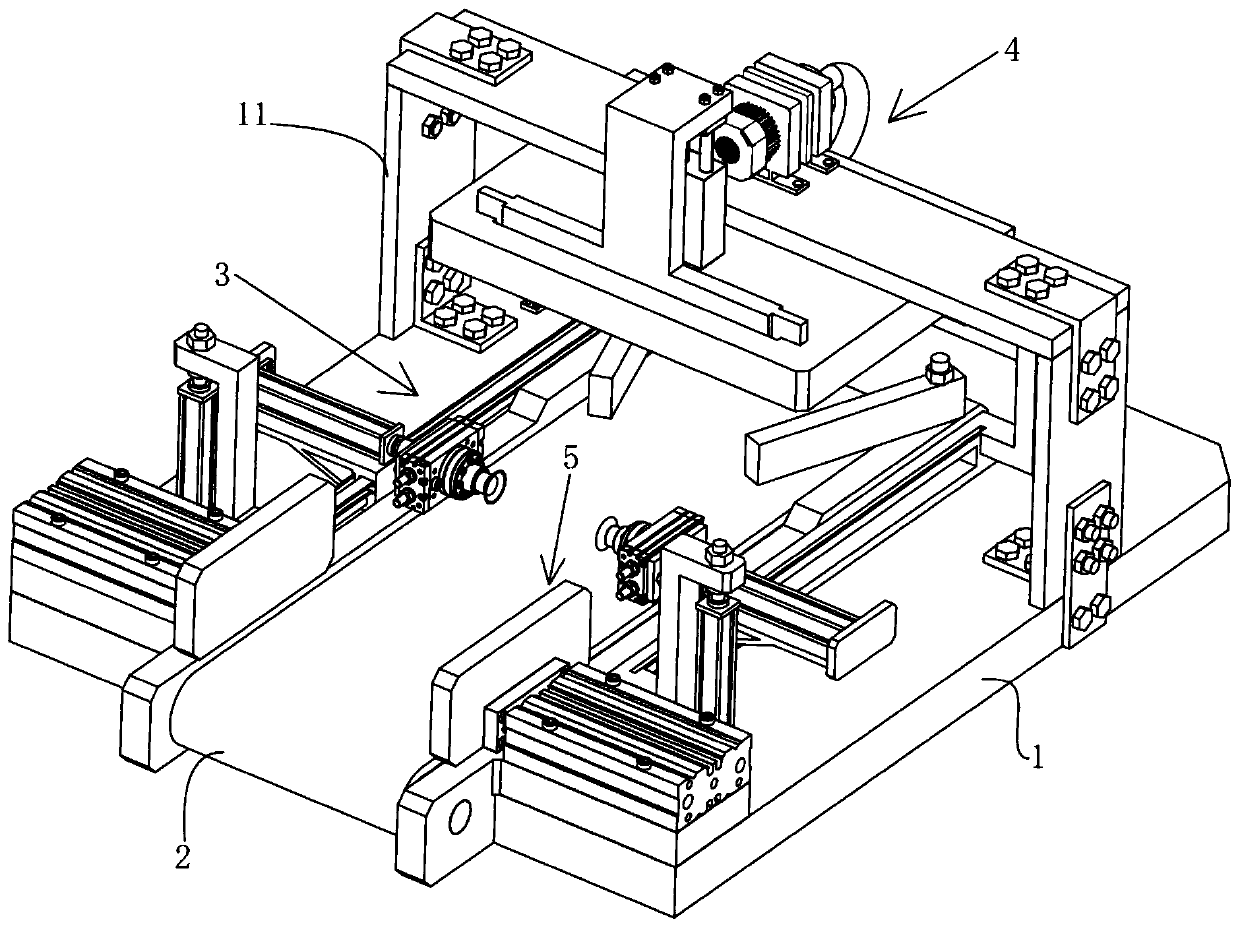

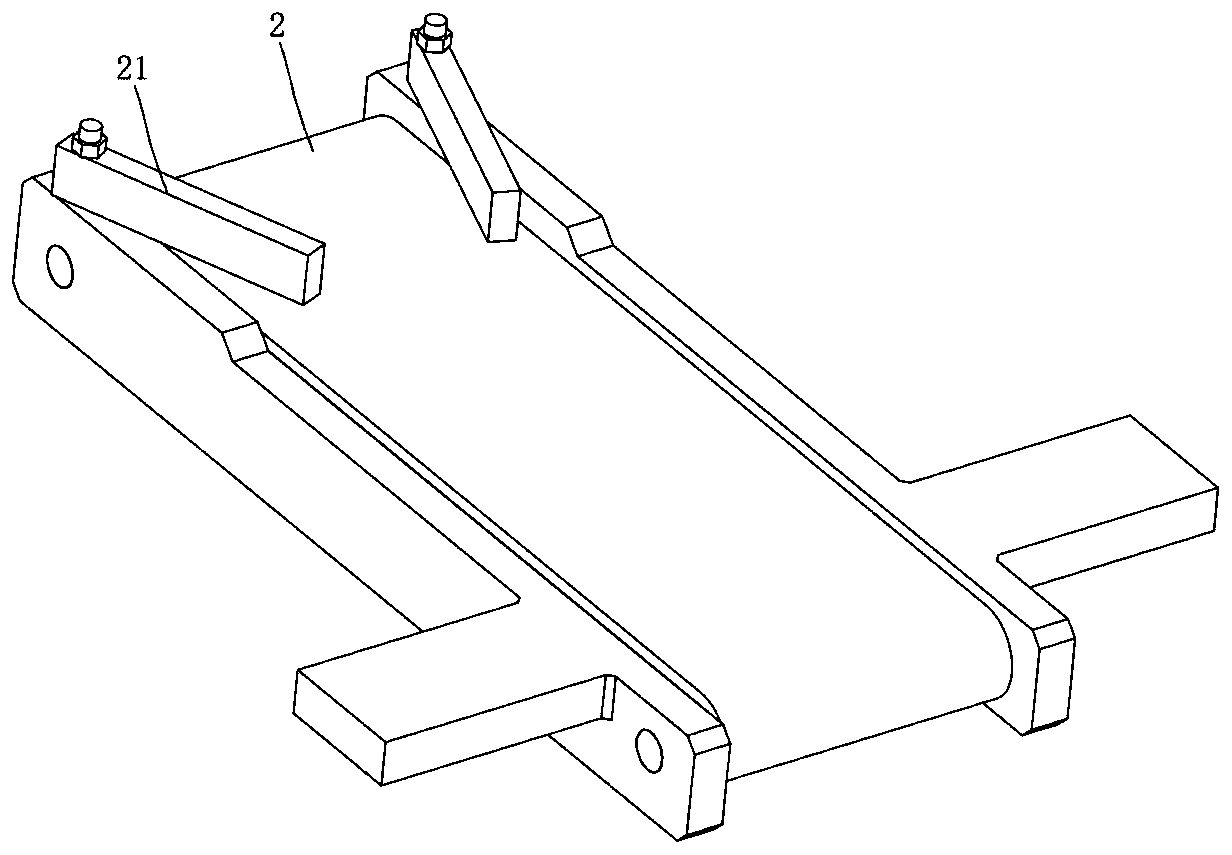

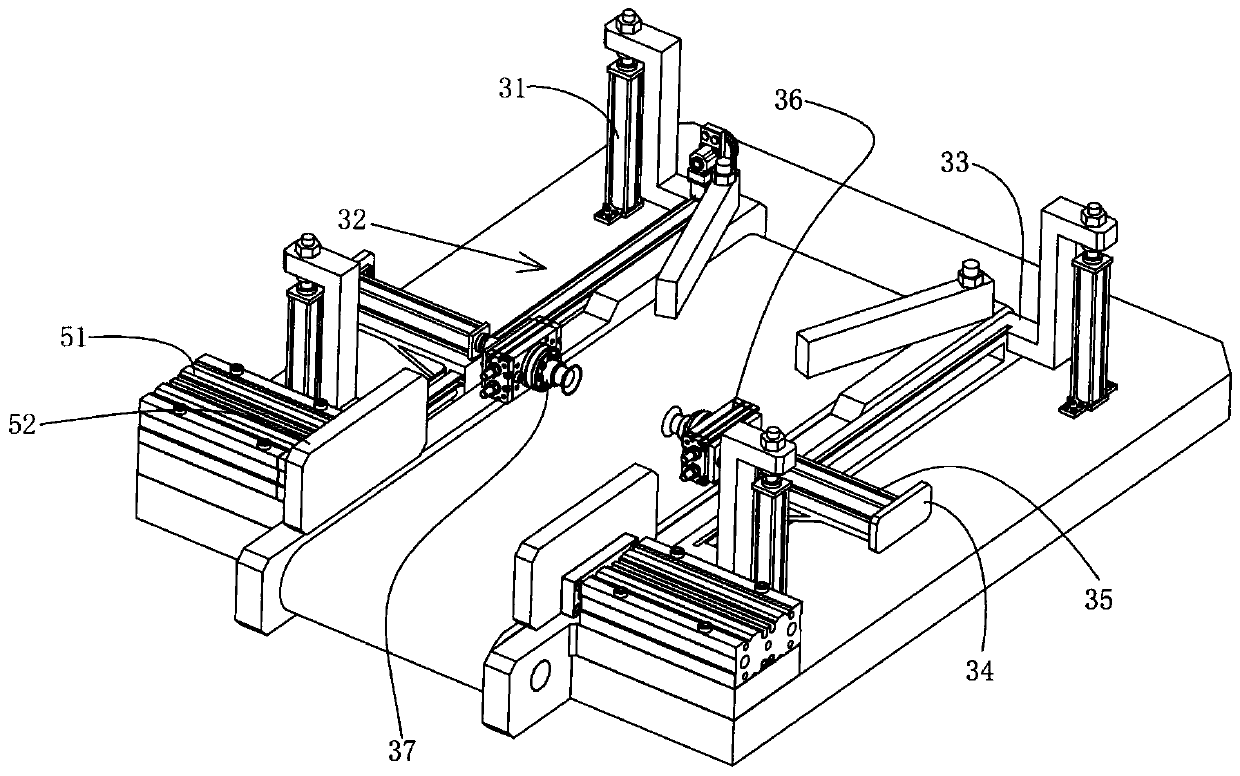

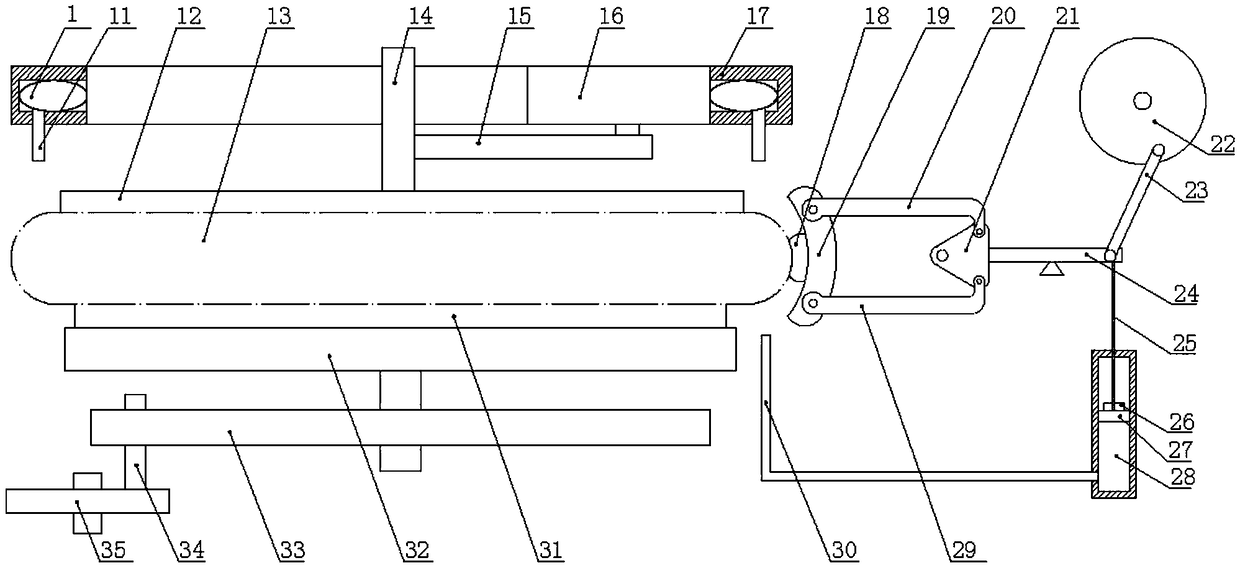

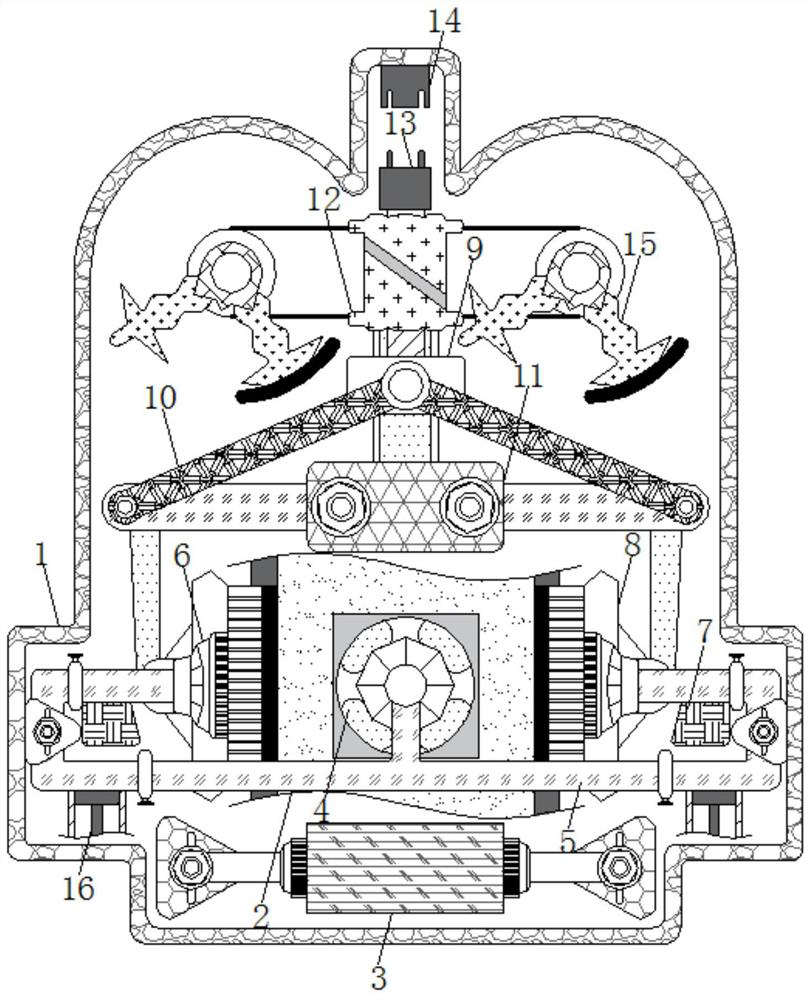

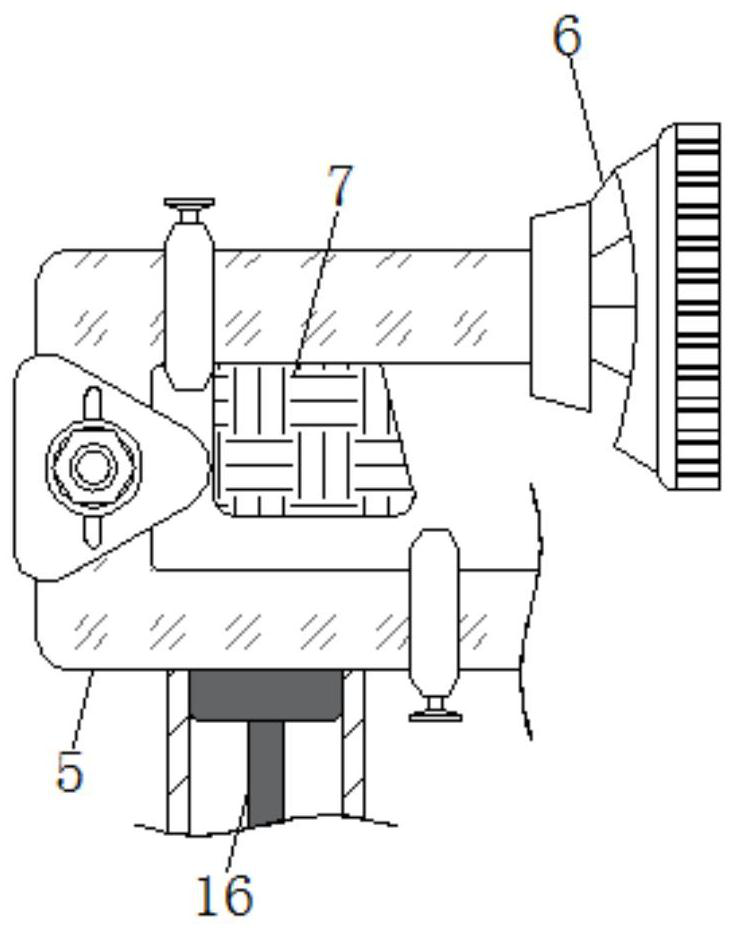

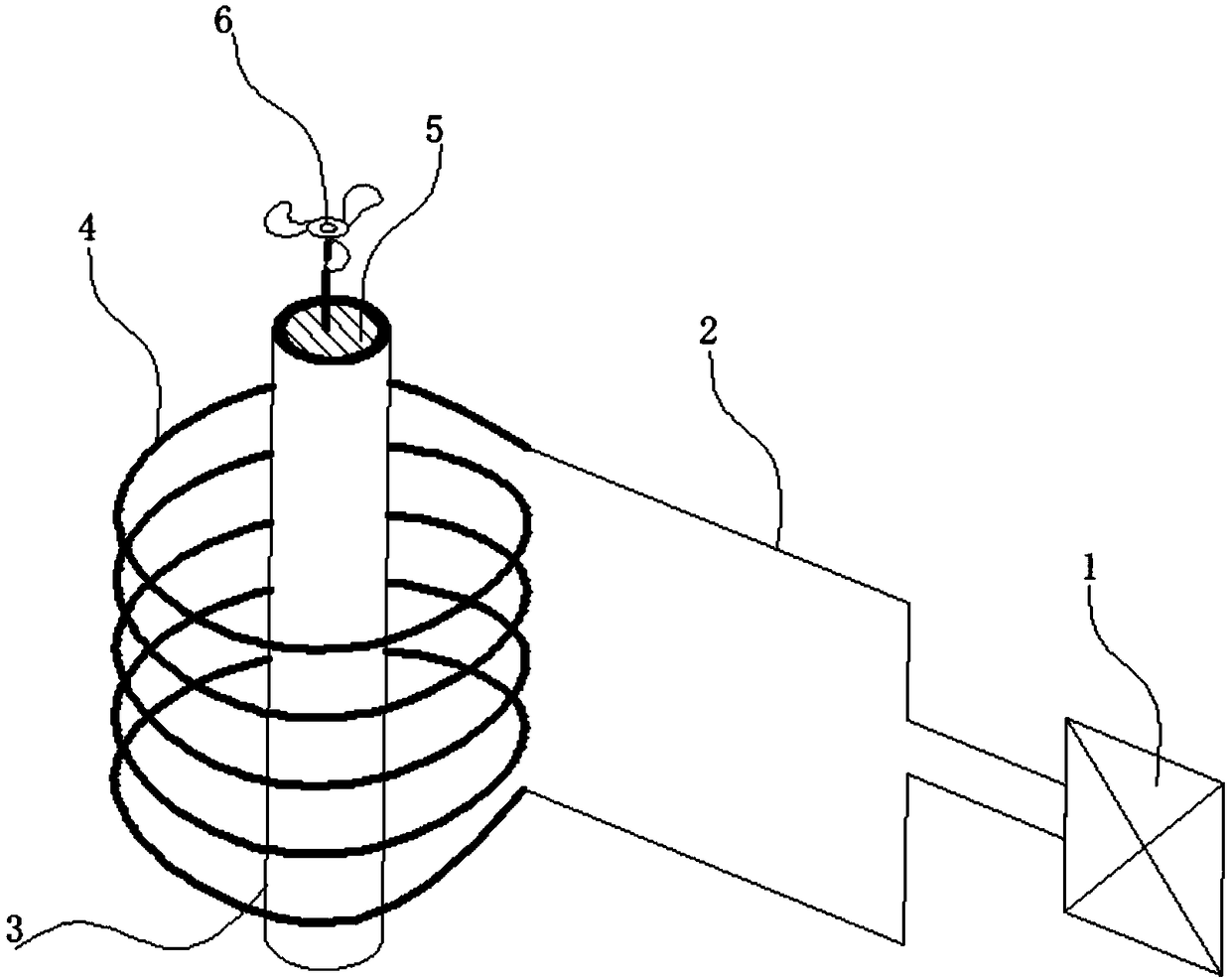

Packaging box film coating and sealing device suitable for different sizes

ActiveCN110435216AImprove efficiencyLaminationPaper-makingBox making operationsEngineeringFilm coating

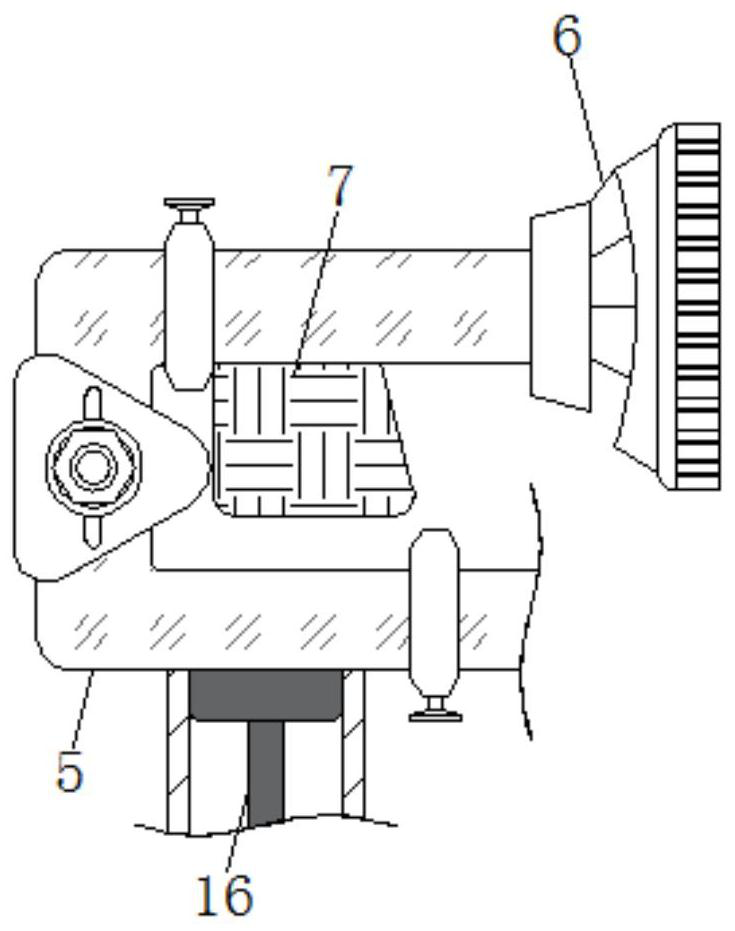

The invention provides a packaging box film coating and sealing device suitable for different sizes. The packaging box film coating and sealing device comprises a bottom plate, a conveying belt, a clamping mechanism, a film coating mechanism and edge sealing mechanisms. The two edge sealing mechanisms are mounted on the bottom plate. The clamping mechanism is mounted on the bottom plate and comprises hydraulic cylinders, a linear drive mechanism, guide rails, sliding blocks, single-axis air cylinders, rotating air cylinders and ejector rods. The film coating mechanism is mounted on a supporting frame and comprises an air bellow, an air pipe, a fan, a hot knife, a dual-axis air cylinder I and a winding roller. A packaging box is clamped by the oppositely-arranged ejector rods, the packagingbox is driven to rotate under the action of the rotating air cylinders, and then packaging boxes of different sizes can be clamped; then, the surface of the packaging box is wrapped by a layer of packaging film, and the situation that bubbles are generated in the film coating process to influence packaging is avoided; the fan inputs negative pressure into the air bellow, and the packaging film isclosely attached to the air below; and when film cutting is carried out on the packaging box with packaging completed, later packaging boxes can continue to be packaged, and packaging efficiency is increased.

Owner:淮北禾获人科技有限公司

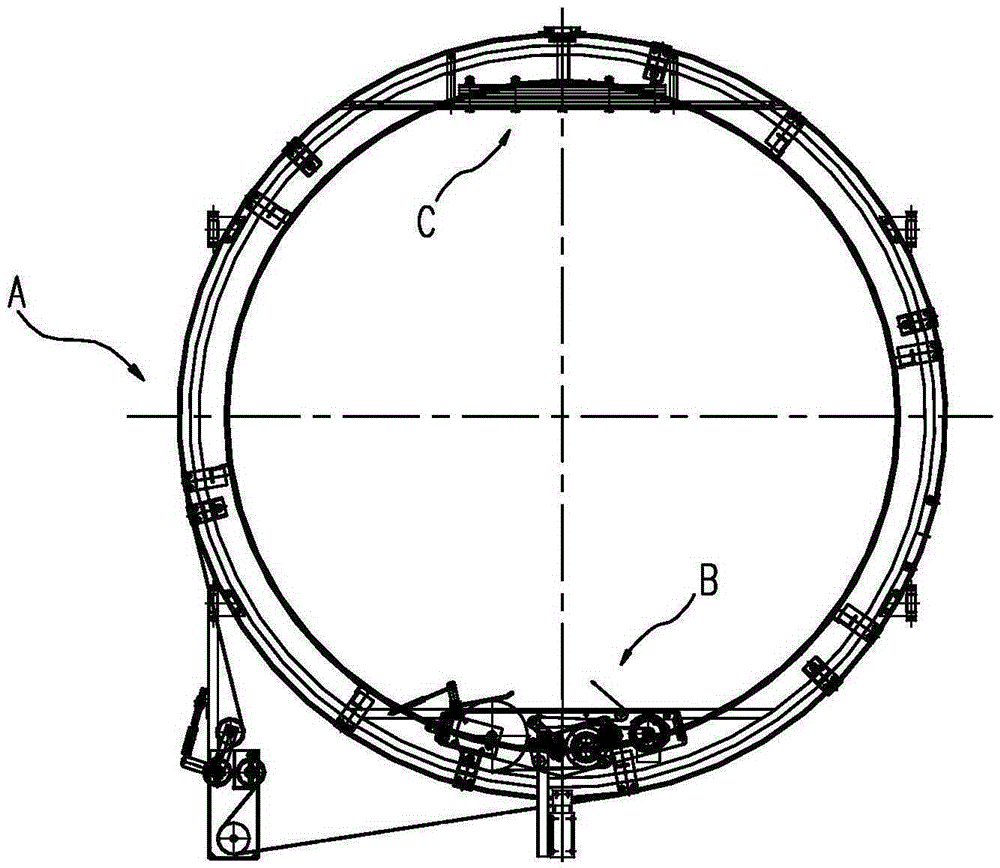

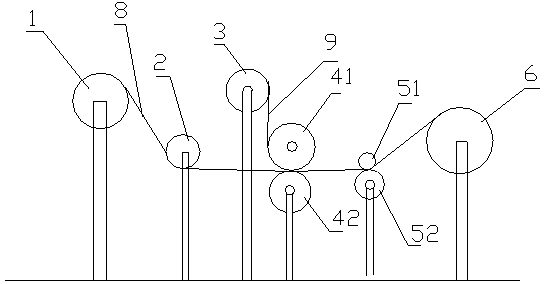

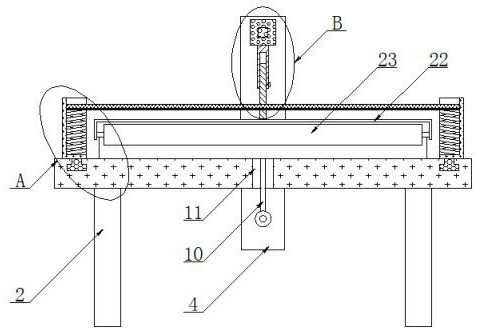

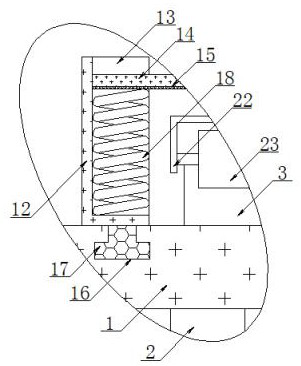

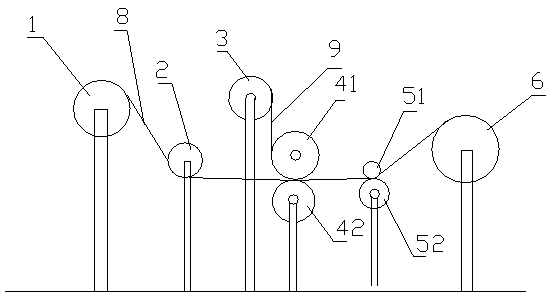

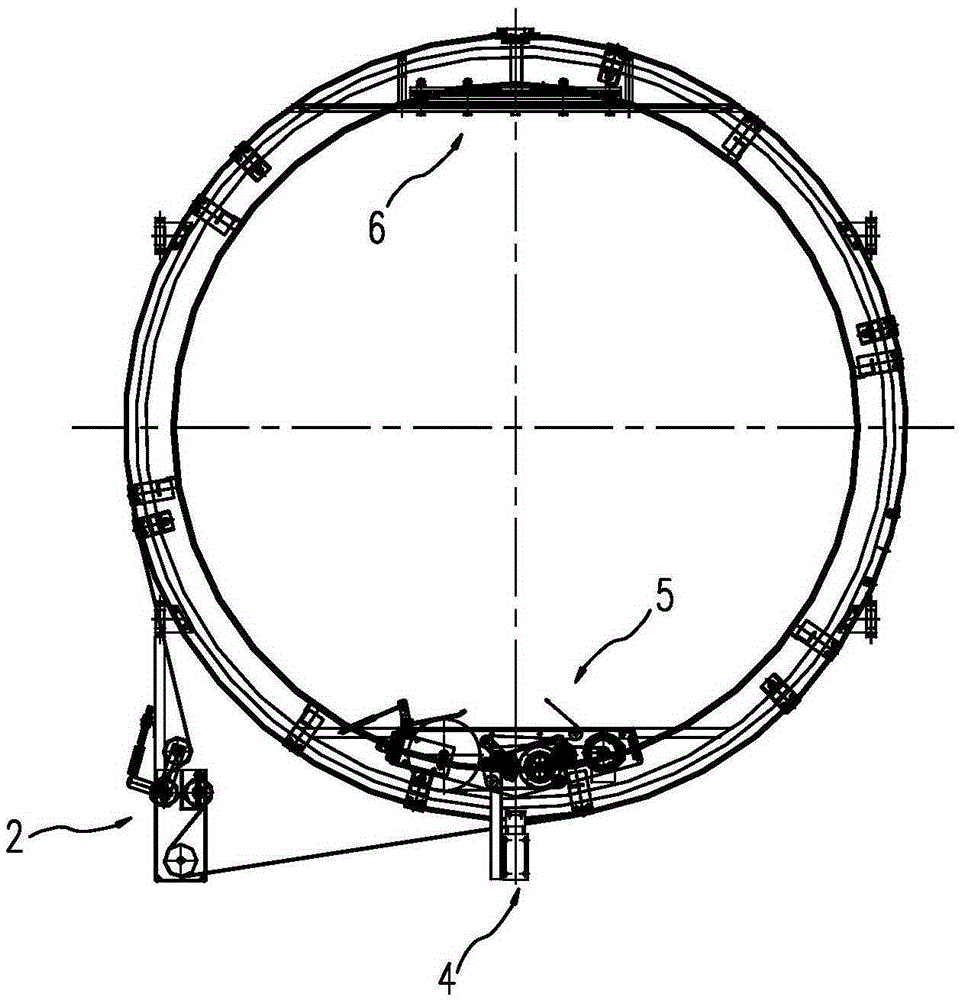

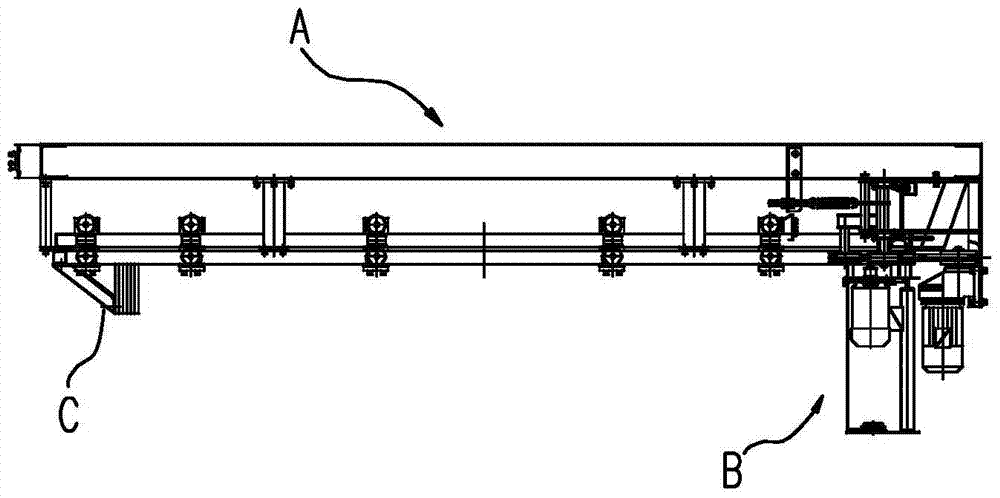

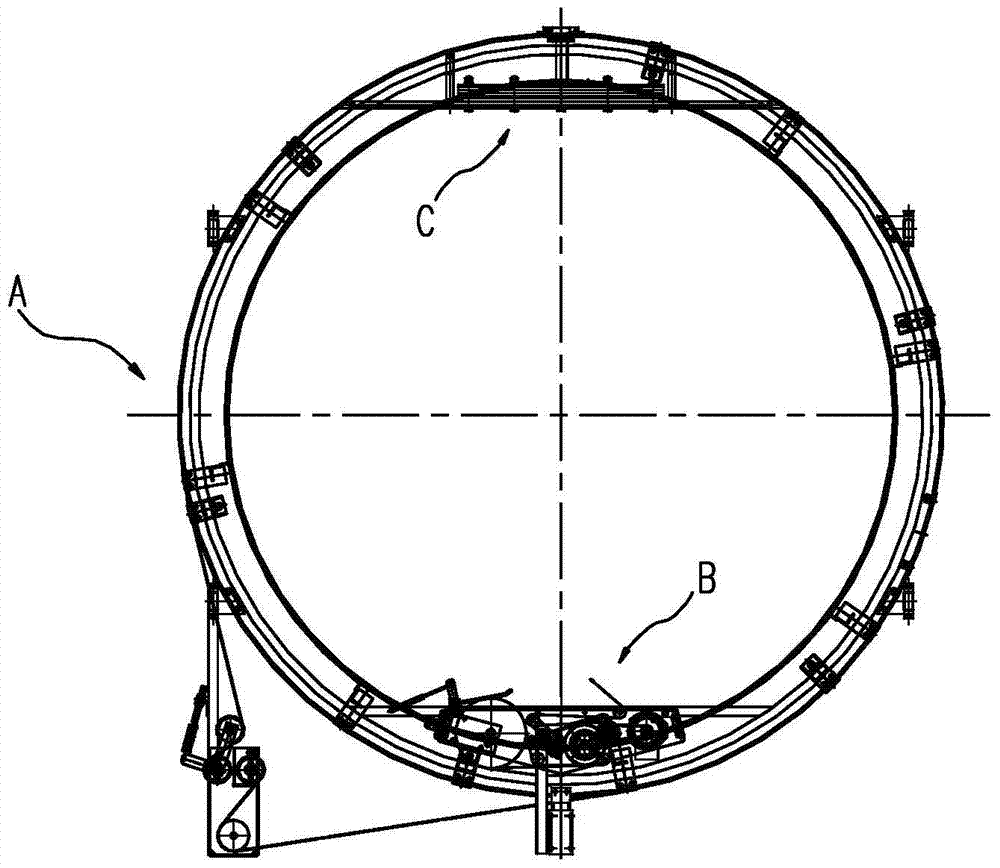

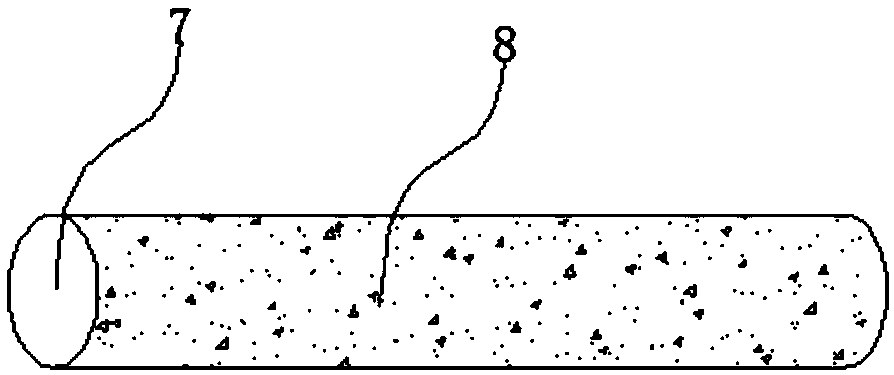

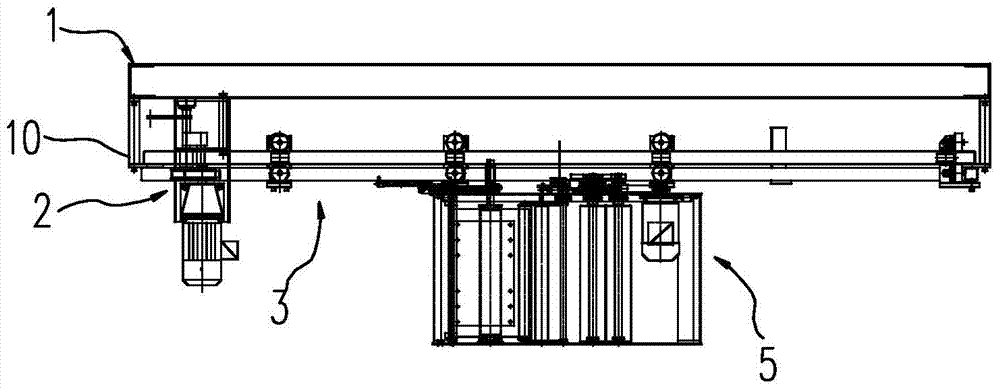

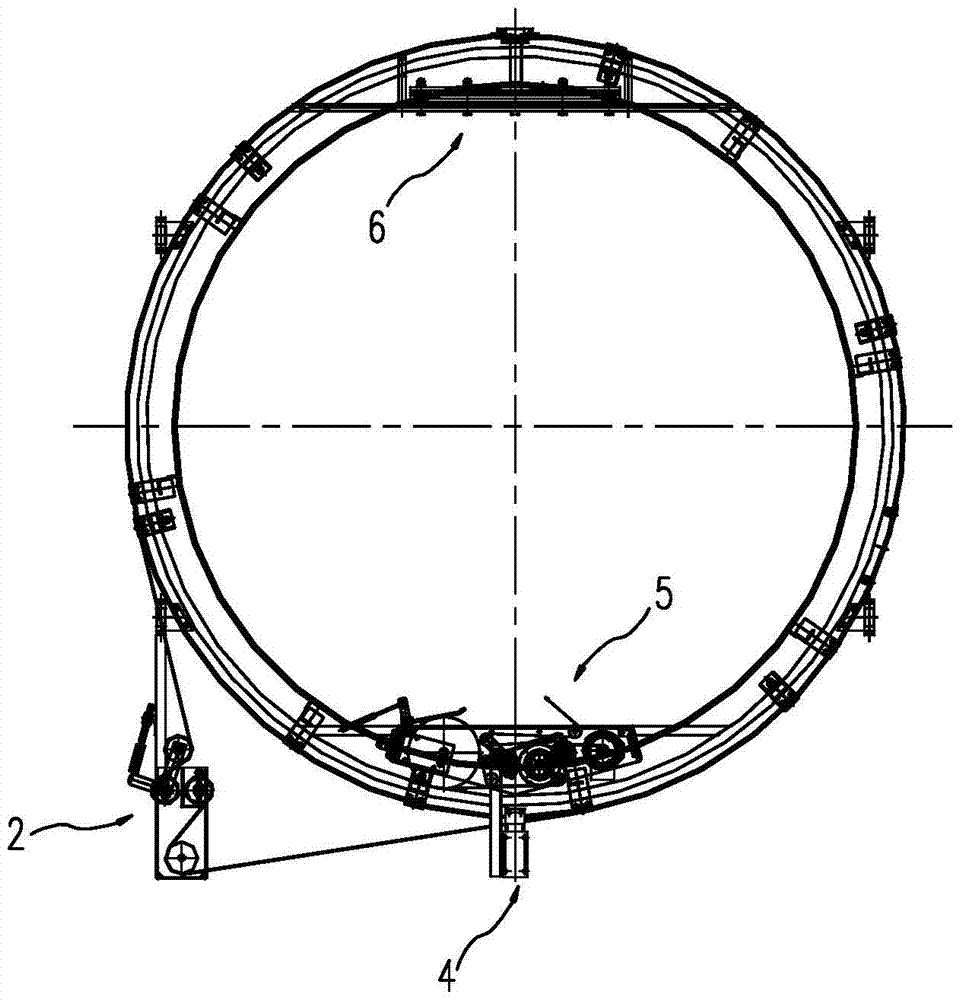

Circular track type film laminating machine

ActiveCN105398592AGuaranteed tensionSmall driving forceWrapping material feeding apparatusWeb rotation wrappingEngineeringEnergy consumption

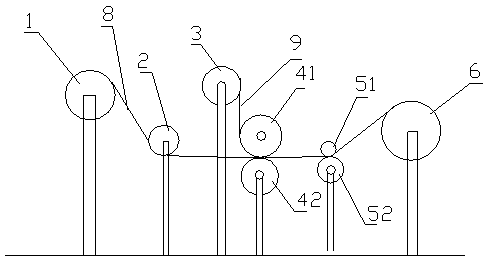

The invention discloses a circular track type film laminating machine. The circular track type film laminating machine comprises a transmission device and a film feeding control device which achieve automatic film laminating. The film feeding control device is fixed to the transmission device and performs rotational motion along with the transmission device. The transmission device comprises a platform rack and further comprises a driving device, a track device and a power picking device, wherein connecting hangers convenient to fix are disposed under the platform rack; the driving device is mounted on the lower portion of the platform rack; the track device is fixedly connected to the lower side of the platform rack through the connecting hangers; the power picking device is disposed on the track device. The film feeding control device comprises a rack and further comprises a film storing mechanism and a film feeding mechanism which are fixedly arranged on the rack and sequentially connected, and a film is made to sequentially pass through the film storing mechanism and the film feeding mechanism to be delivered to a film clamping rod. During film laminating, an object does not rotate, and a film laminating mechanism rotates, so that the needed driving force is greatly reduced and the energy consumption is decreased. Meanwhile, the film feeding control device can make the film keep tensioned to a certain degree all the time, so that the film is not tightly tensioned and loosened, and the automation degree is high.

Owner:HEFEI GENERAL MACHINERY RES INST

Polishing device for furniture plate

PendingCN108705438AAchieve polishImprove processing efficiencyEdge grinding machinesGrinding carriagesEngineeringFurniture manufacturing

The invention relates to the technical field of furniture manufacturing, in particular to a polishing device for furniture plates. The polishing device comprises a processing table. A sucker is arranged on the processing table. A grooved wheel is rotationally connected to the lower portion of the processing table. A rotating wheel is rotationally arranged at one side of the grooved wheel. A roundpin is arranged on the rotating wheel. The round pin is intermittently and slidably connected with a groove of the grooved wheel. A turntable is rotationally arranged at one side of the processing table. An upper connecting rod and a lower connecting rod are correspondingly arranged at the upper part and the lower part of the turntable. Both the upper connecting rod and the lower connecting rod are hinged with the turntable. An arc-shaped polishing plate is arranged at one side of the turntable. A polishing wheel is arranged on the polishing plate. The free end of the upper connecting rod andthe free end of the lower connecting rod are correspondingly hinged with the two ends of the polishing plate. A driving mechanism is arranged on the other side of the turntable. The driving mechanismis connected with the turntable. The polishing device solves the problems of troublesome operation and low efficiency of edge polishing of circular plates in the prior art.

Owner:四川三虎家居有限公司重庆分公司

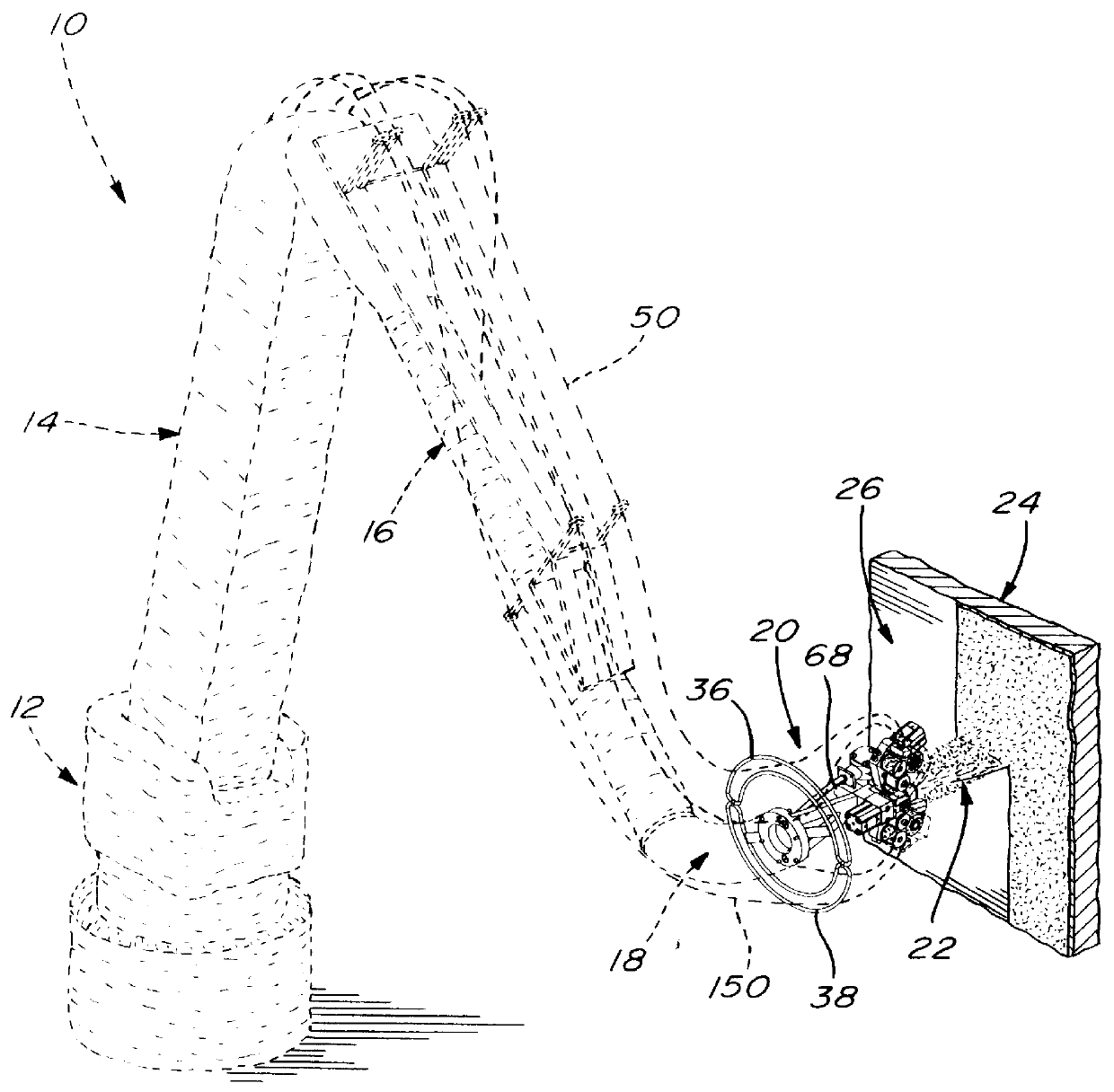

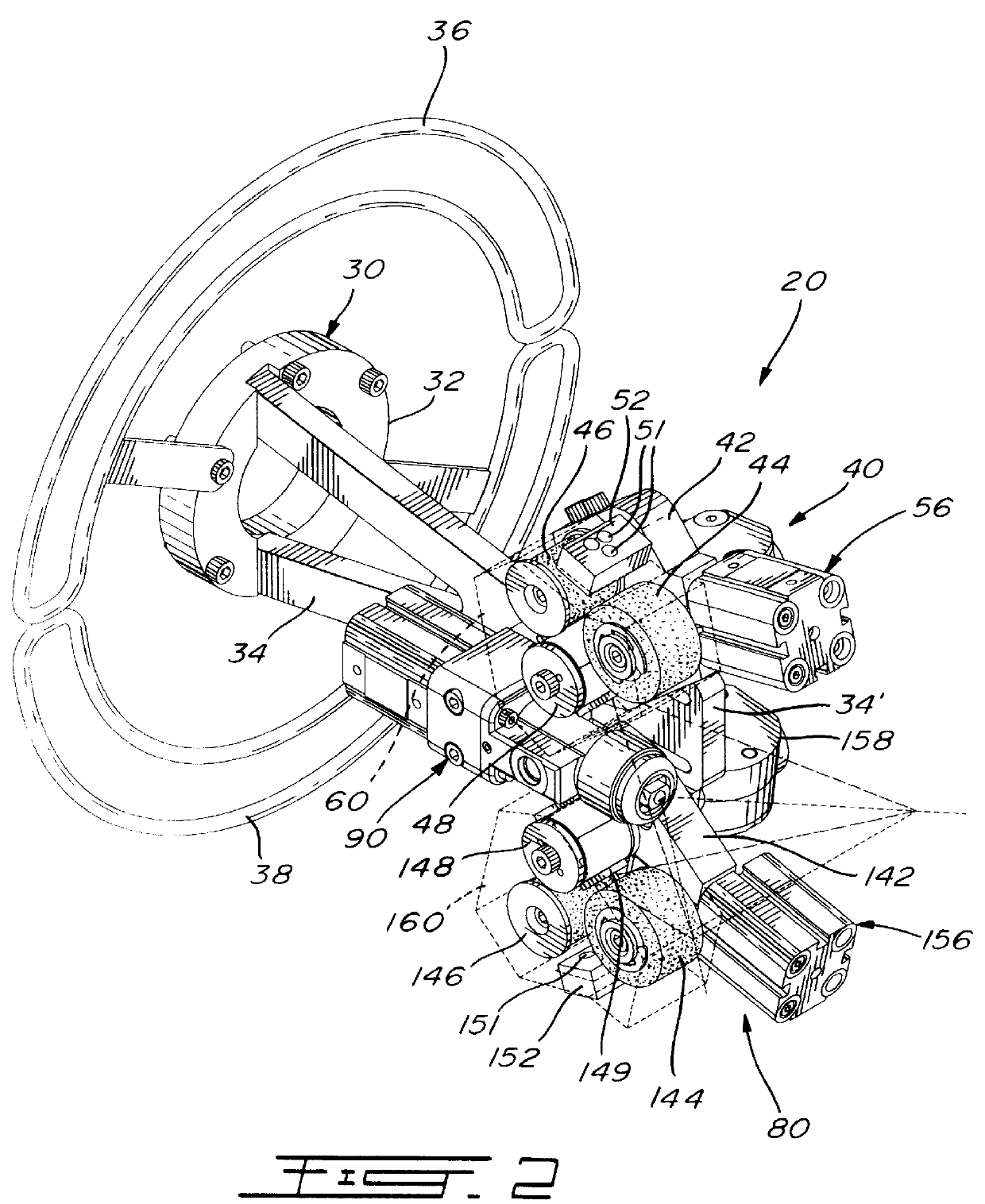

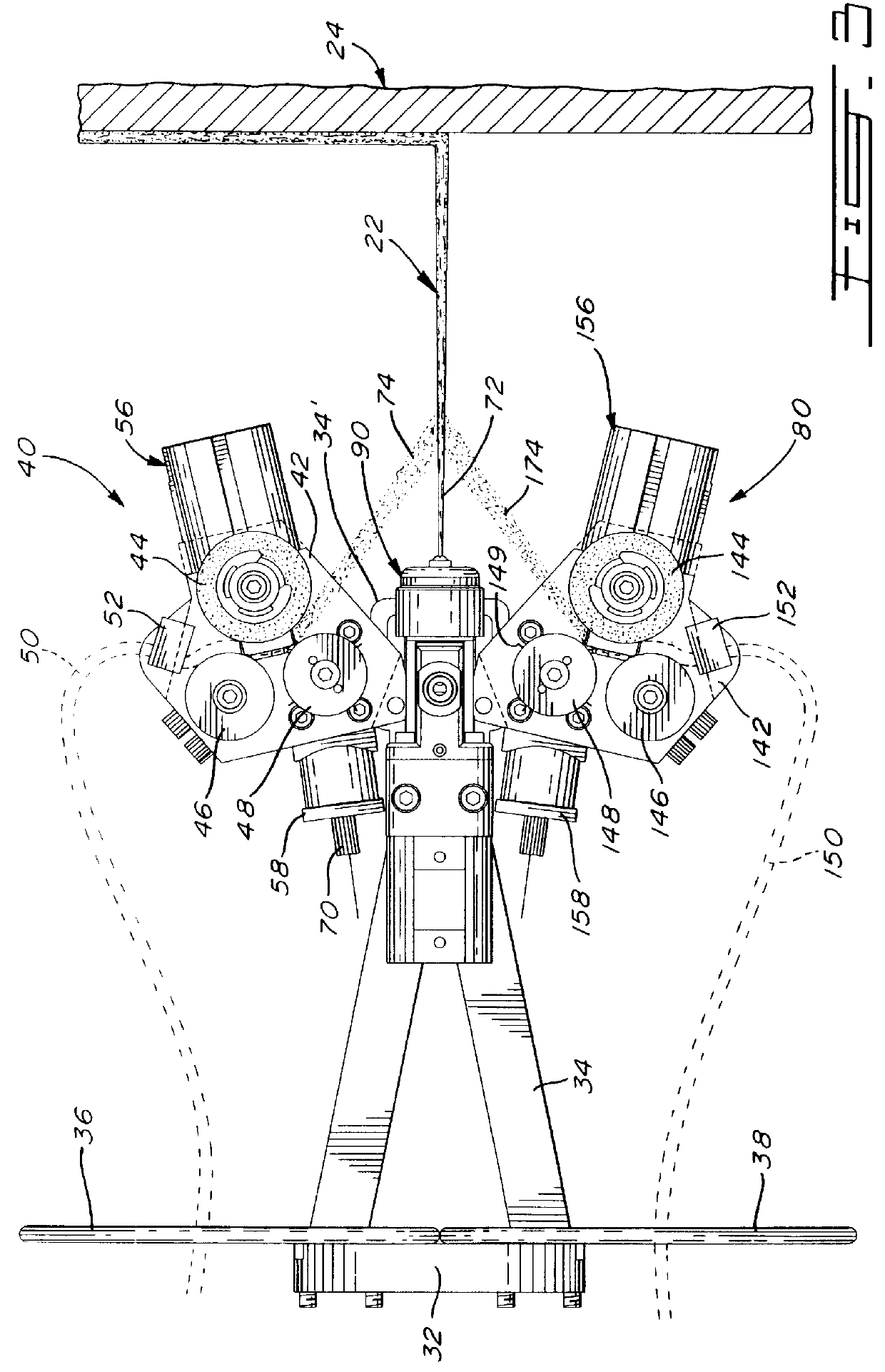

Twin chopper device for spray-up molding

InactiveUS6126092AIncrease torqueEmission reductionBurnersFire rescueSpray nozzleMechanical engineering

The twin chopper of the present invention consists of a pair of roving choppers, each chopper being disposed on either side of a resin spraying nozzle. Each chopper comprises a rotatably driven cutter roller, a rotatable friction roller cooperating with the cutter roller, and an idler roller cooperating with the friction roller for feeding roving strands between the friction roller and the cutter roller. The outlet of the first chopper is so disposed relative to the nozzle as to discharge cut rovings over and onto the flat spray of resin while the outlet of the second chopper is so disposed relative to the nozzle as to discharge cut rovings under and onto the flat spray so that the resin spray is coated with roving cuts on both sides thereof from both choppers as the spray is directed onto the open mold surface.

Owner:CAMOPLASY INC

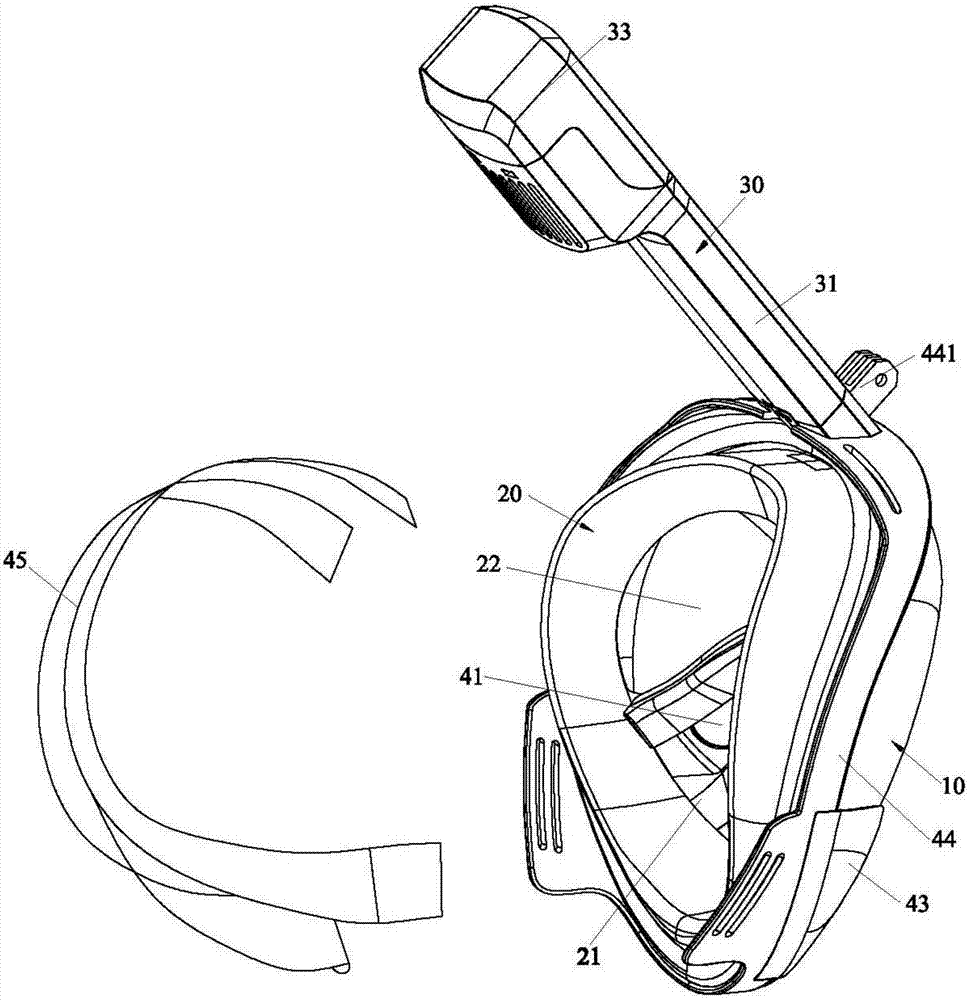

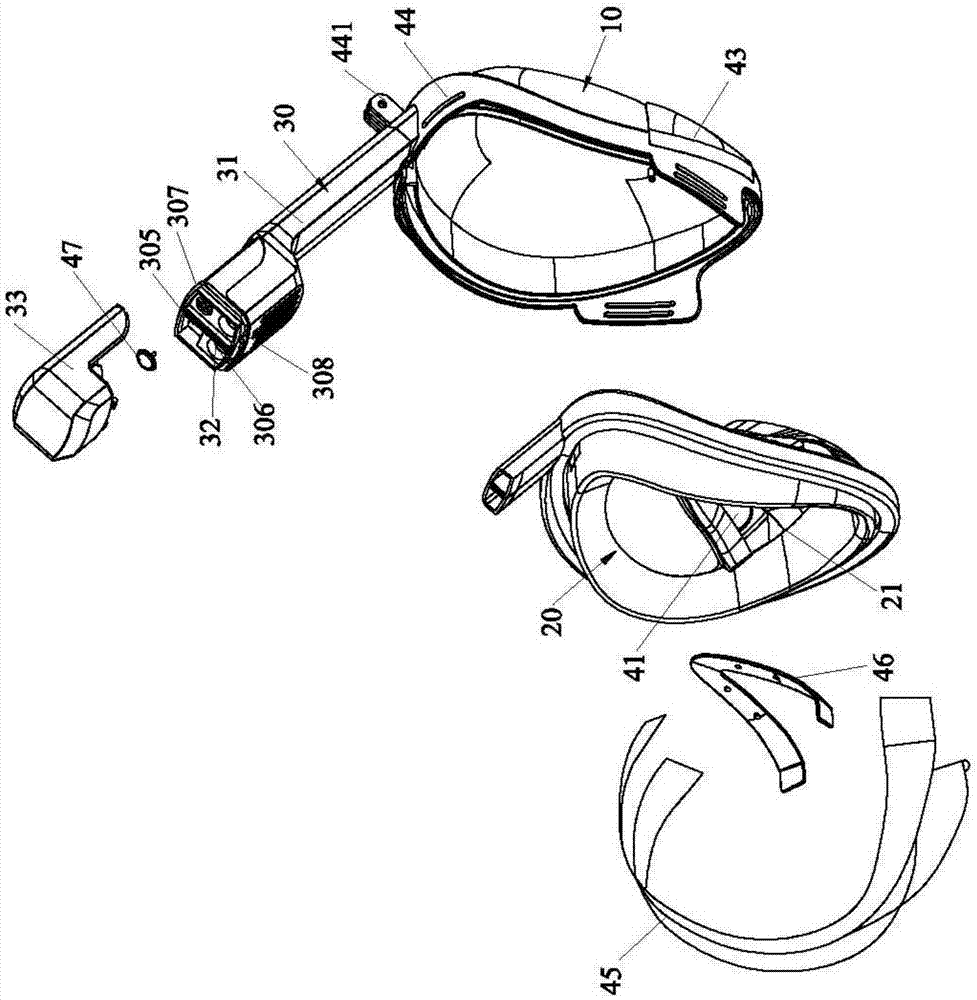

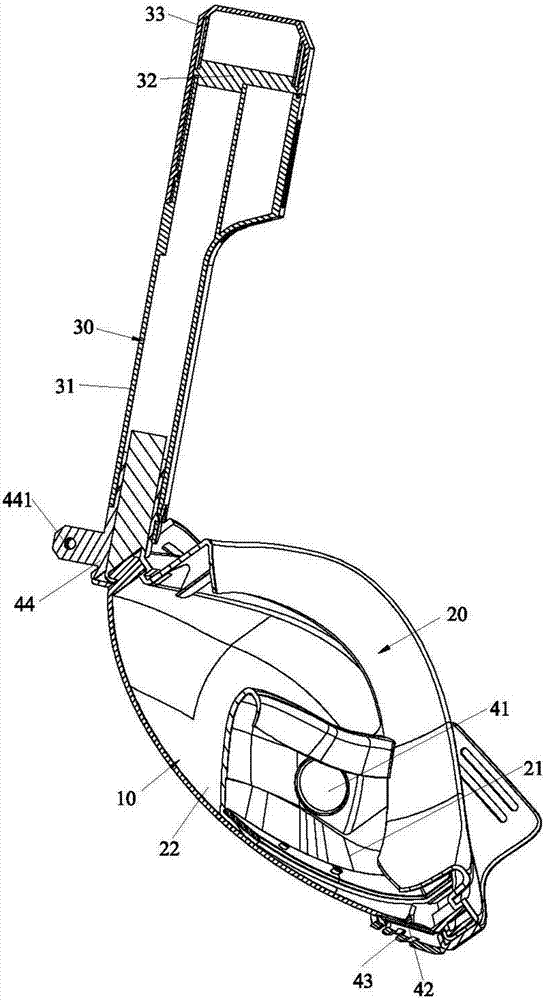

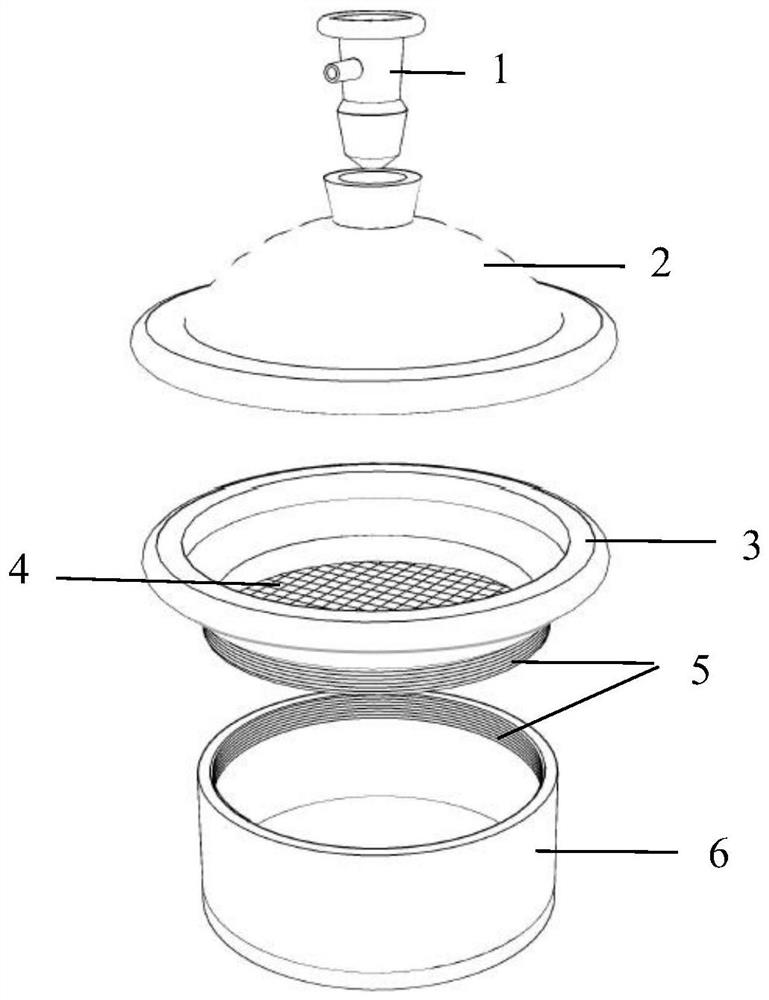

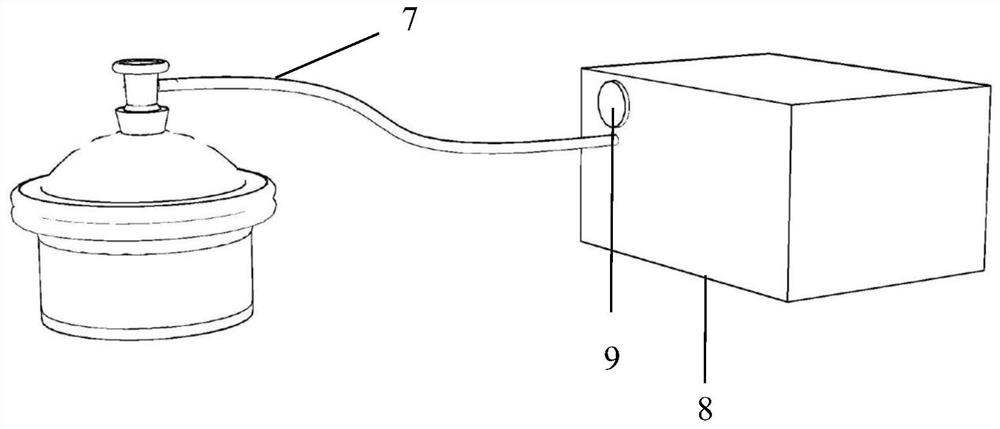

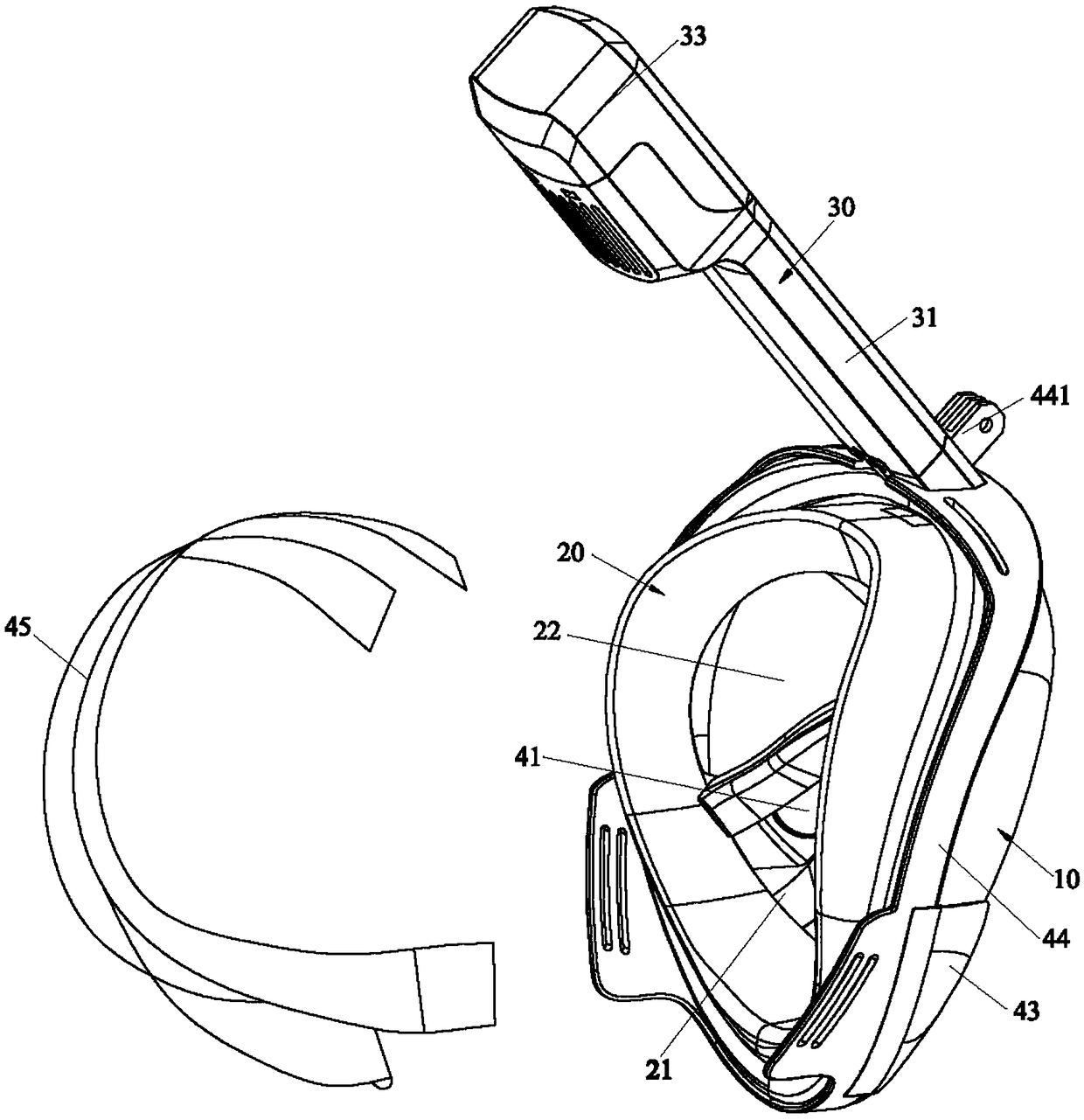

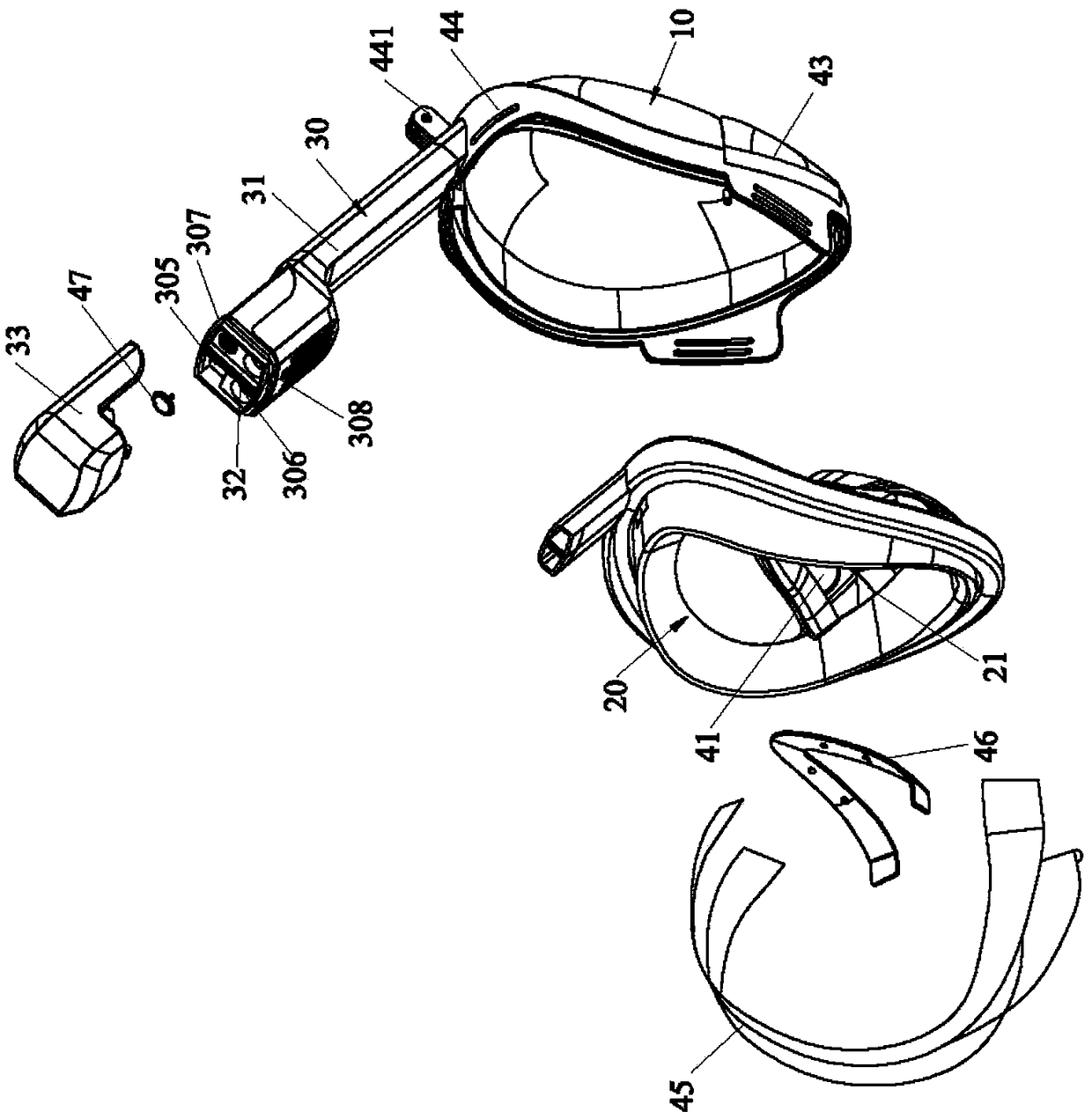

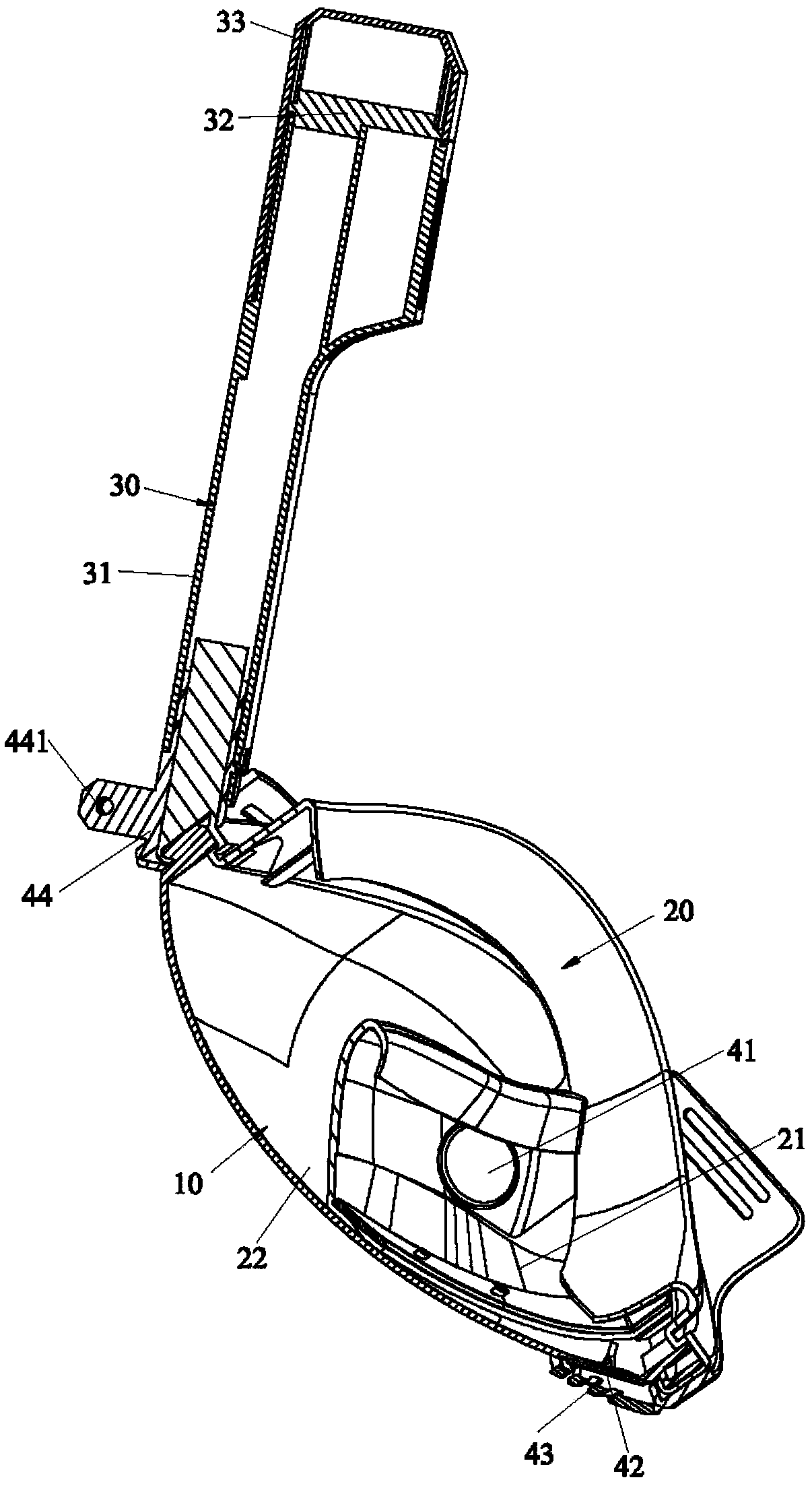

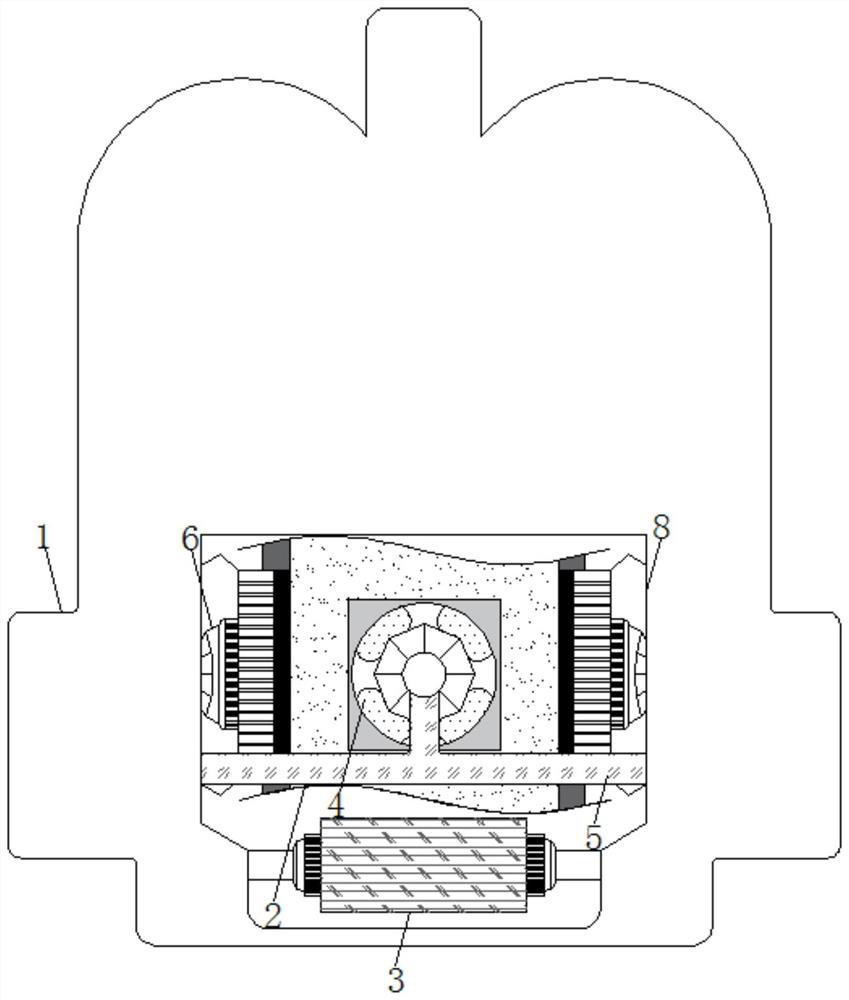

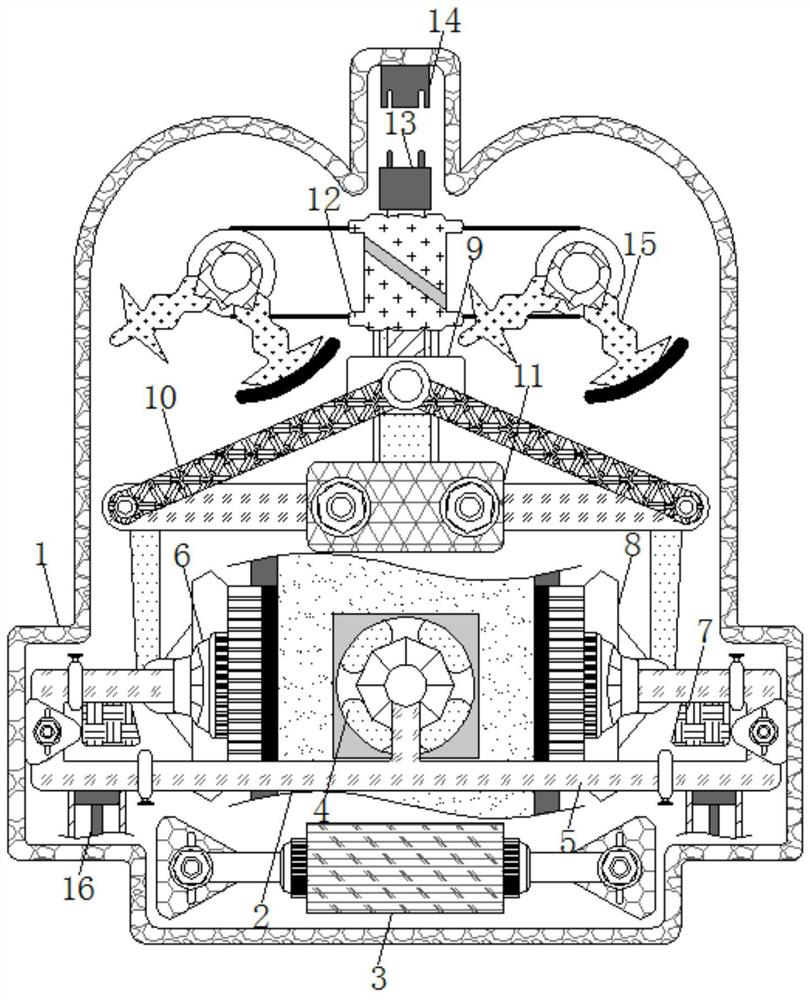

Single-inlet single-outlet snorkeling face mask

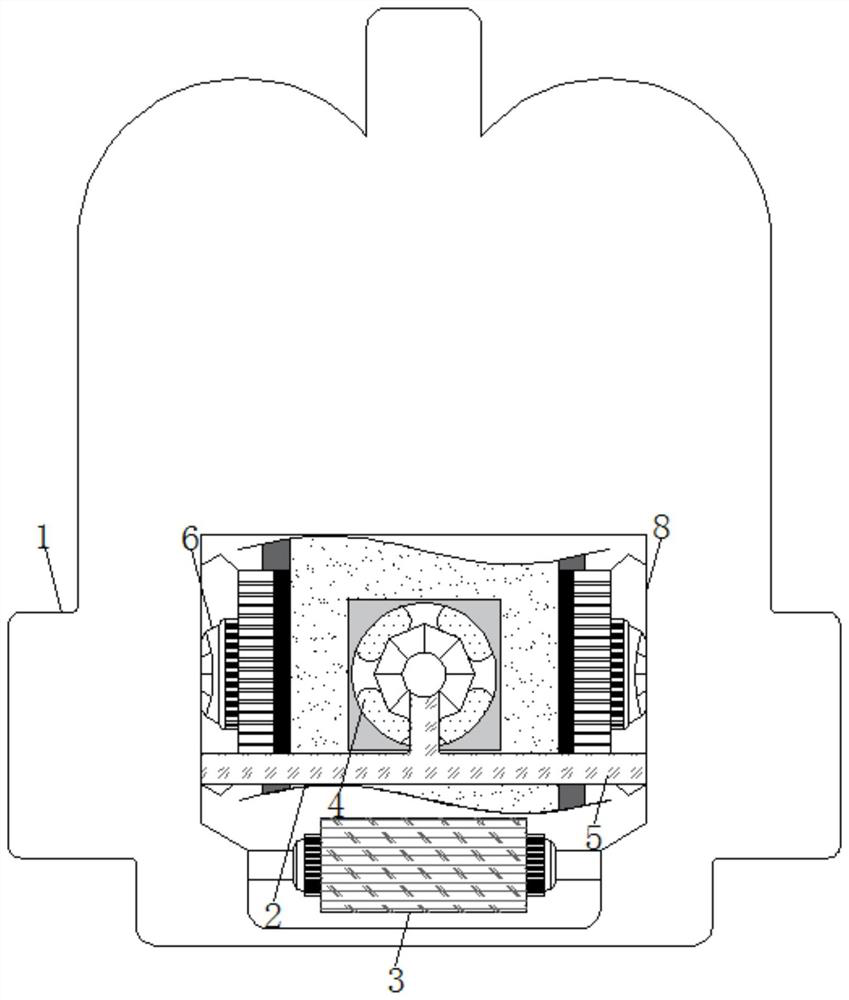

The invention discloses a single-inlet single-outlet snorkeling face mask. The single-inlet single-outlet snorkeling face mask comprises a transparent face mask body, a silica gel face mask body and a two-channel breathing pipe, wherein the silica gel face mask body is mounted on the inner side surface of the transparent face mask body; a breathing out cavity is formed in the inner side surface of the silica gel face mask body; a breathing in cavity is formed between the outer side surface of the silica gel face mask body and the inner side surface of the transparent face mask body; a first one-way valve piece allowing the breathing in cavity to communicate with the breathing out cavity is arranged on the silica gel face mask body; the two-channel breathing pipe is arranged on the transparent face mask body, and is provided with a breathing in channel and a breathing out channel; and a second one-way valve piece is arranged at the tail end of the breathing out channel. According to the single-inlet single-outlet snorkeling face mask disclosed by the invention, the two-channel breathing pipe is adopted, and the first one-way valve piece and the second one-way valve piece are fitted, so that a single-inlet single-outlet circulating structure is formed; and the air intake and the air out are thoroughly separated, and waste air and fresh air cannot merge, so that the problems of being disturbance in respiration and heart stuffy are solved, and a person also need not to worry about the situation that physical damage is generated caused by that the waste gas is repeatedly breathed in.

Owner:SHENZHEN CP LINK ELECTRONICS CO LTD

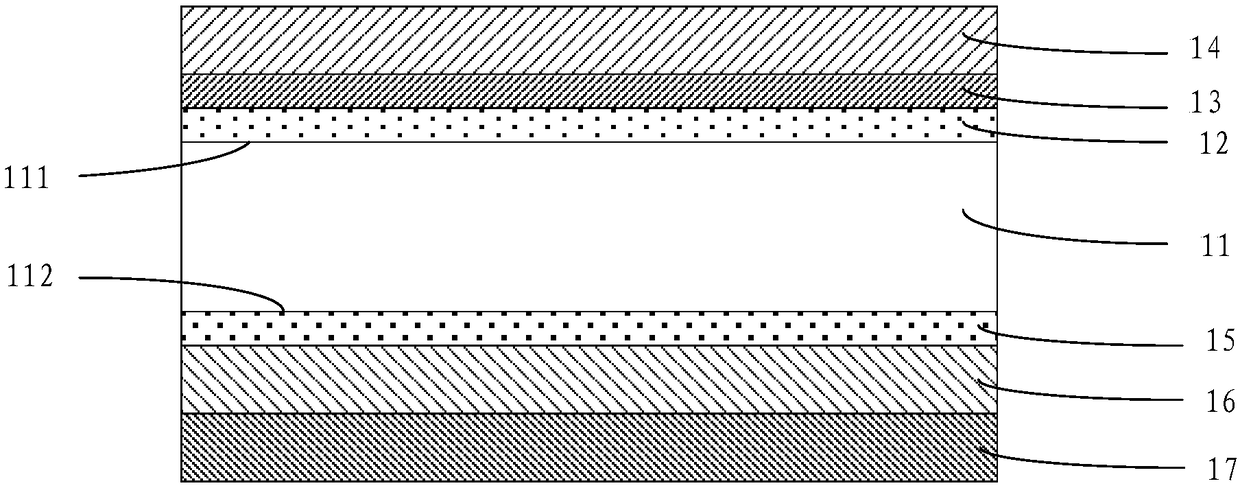

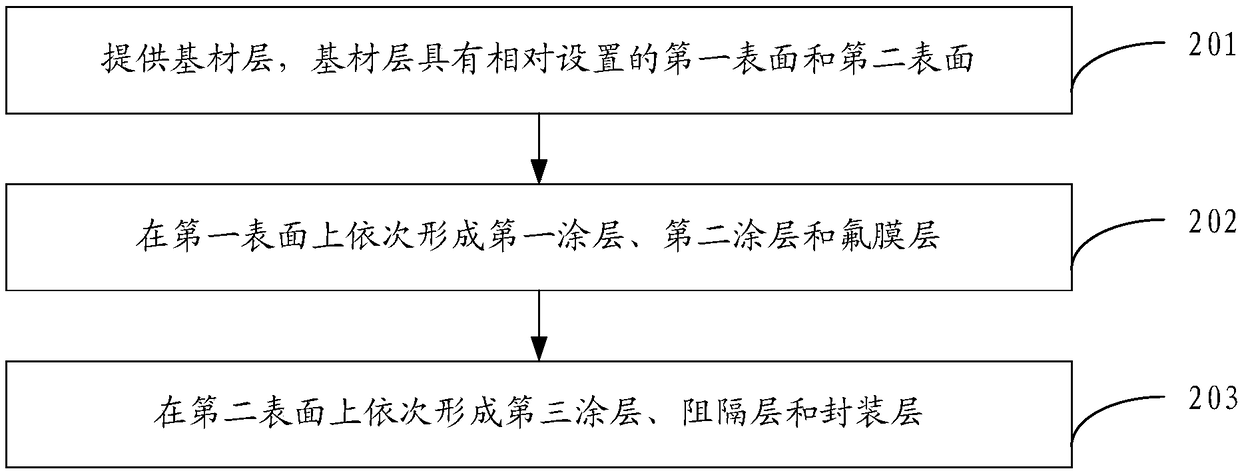

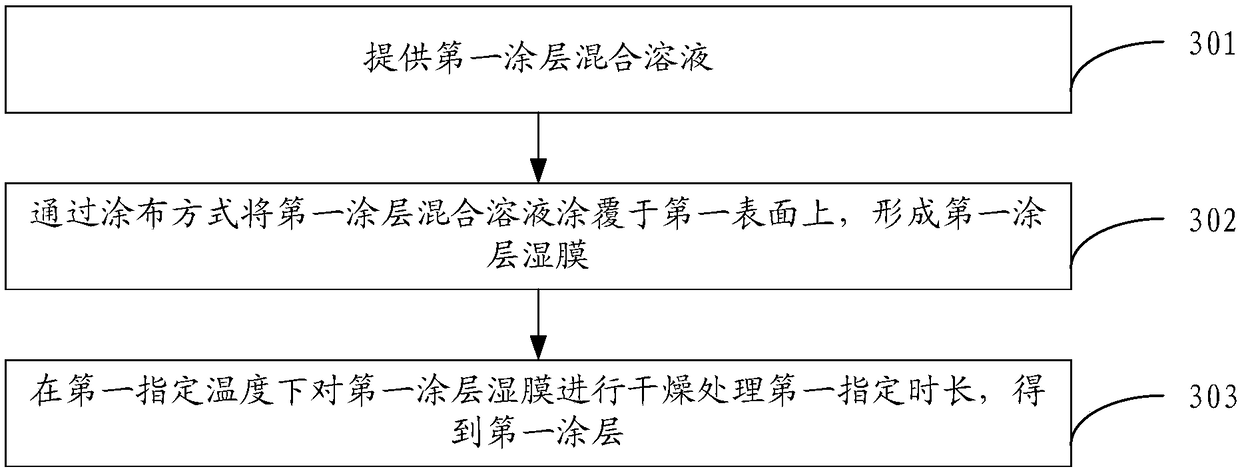

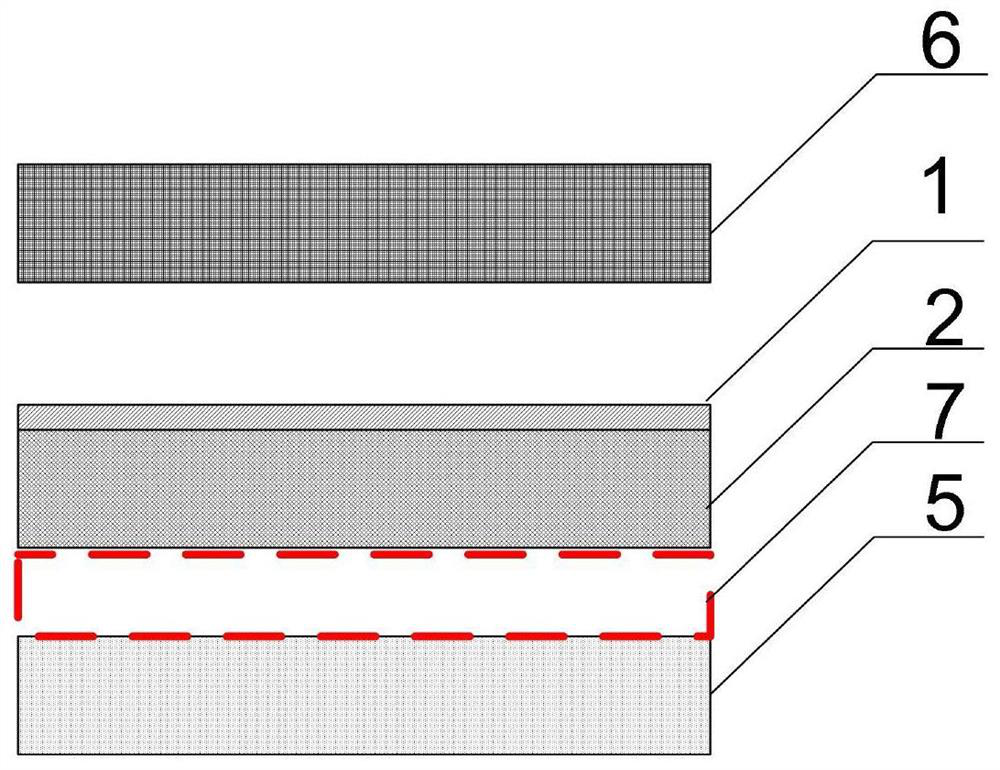

Solar cell packaging plate and preparation method thereof, and solar cell

InactiveCN108735842AMeet diverse product needsHigh light transmittancePhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention provides a solar cell packaging plate and a preparation method thereof, and a solar cell; the solar cell packaging plate with rich colors can be prepared through a first coating layer, and therefore the requirements of diversified products of the solar cell can be met; a fluorine film layer is bonded through a second coating layer, so that the light transmittance and the anti-aging effect of the solar cell packaging plate are improved, and meanwhile, the solar cell packaging plate is more resistant to abrasion and scratch, and has a self-cleaning function; the adhesion force of ablocking layer can be improved by arranging a third coating layer; due to the arrangement of the blocking layer, the solar cell packaging plate has relatively high water resistance; the light transmittance and the ageing resistance of the solar cell packaging plate can be further improved by arranging a packaging layer, and the solar cell packaging plate can resist aging for more than 25 years, can be stored and laminated more easily, and is safe and environment-friendly; and meanwhile, a simple packaging process, product integration, convenience in use, a time-saving and efficient subsequentpackaging process and relatively low cost are achieved.

Owner:BEIJING HANERGY PV TECH CO LTD

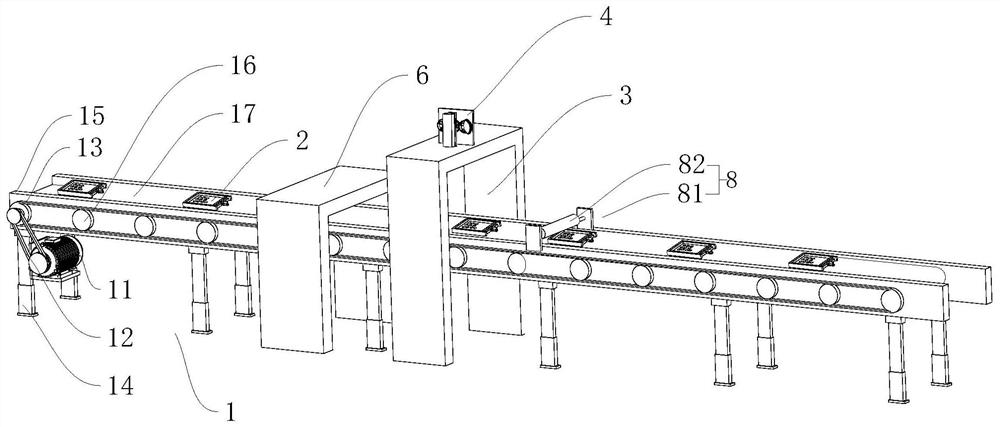

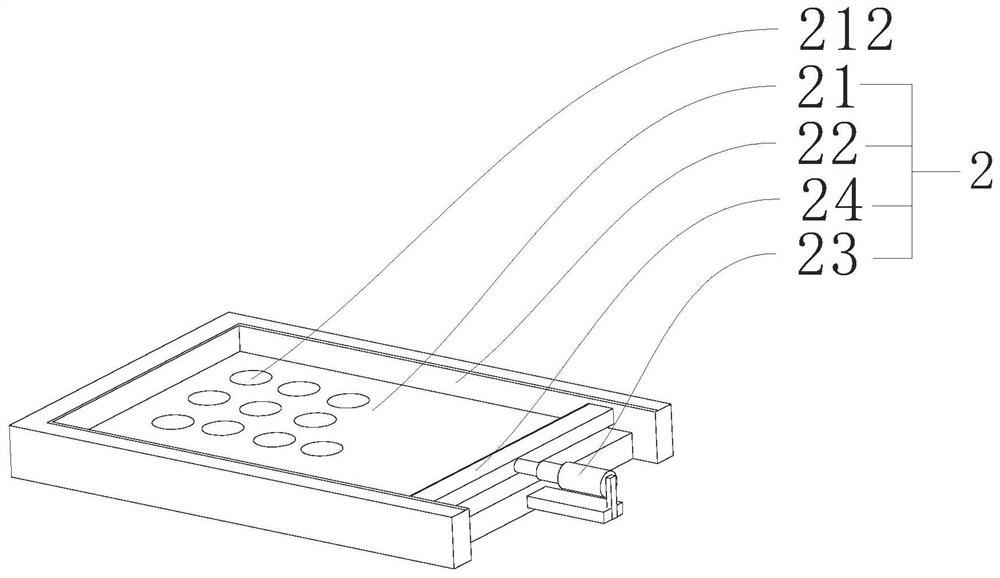

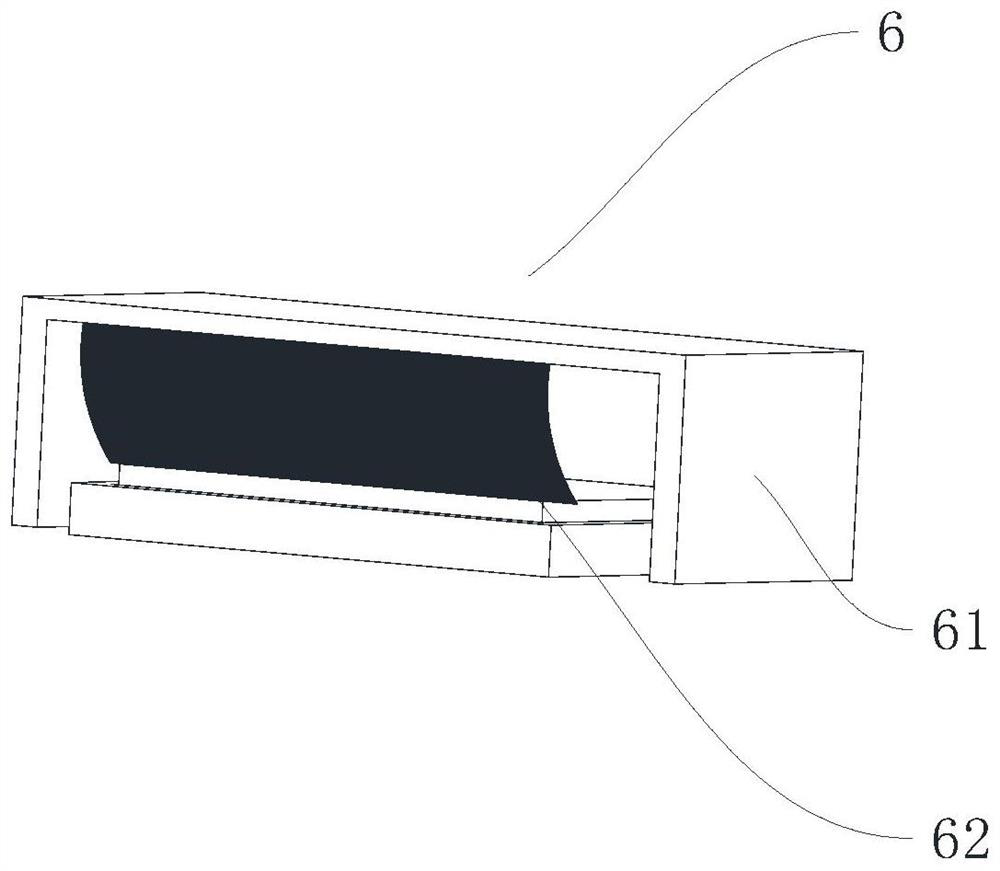

Surface treatment system for manufacturing LED liquid crystal display screen

InactiveCN112590186ALaminating speed is fastImprove lamination efficiencyCleaning using toolsLiquid-crystal displayLED display

The invention relates to the technical field of manufacturing of display screens, and particularly relates to a surface treatment system for manufacturing an LED liquid crystal display screen. The system comprises a transmission mechanism, a fixing mechanism, a film rolling mechanism, a film coating mechanism and a cutting mechanism, wherein the transmission mechanism comprises a first driving motor, a main transmission belt, a slave transmission belt, supporting legs, supporting frames, transmission rollers and a conveyor belt, the fixing mechanism comprises a fixing plate, a C-shaped baffle,a telescopic air cylinder and a material abutting plate, the film rolling mechanism comprises a C-shaped frame, a fixing rod, a first conveying roller set, a second conveying roller set, a guide roller set, a film rolling rod and a rotating motor, the film coating mechanism comprises a supporting plate, a second driving motor, a driving gear, a driven gear, a driving plate gear, a pressing rod, apressing block, a sliding block and a limiting rod, and the cutting mechanism comprises an electric push-pull rod and a cutter. The system has the advantages of being high in film laminating speed, high in film laminating efficiency, and low in cost when a large number of LED display screens are subjected to film laminating operation.

Owner:黄浩

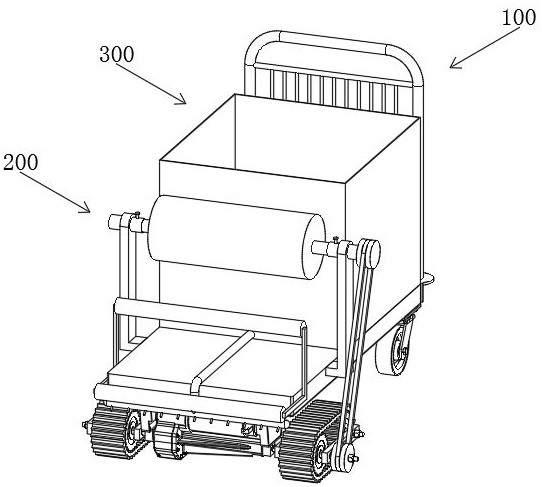

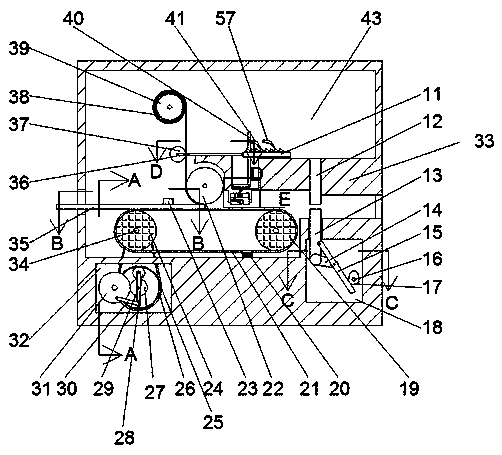

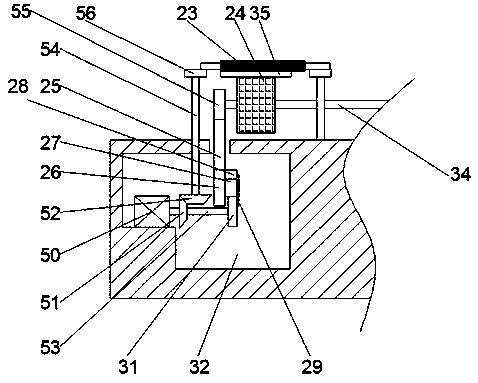

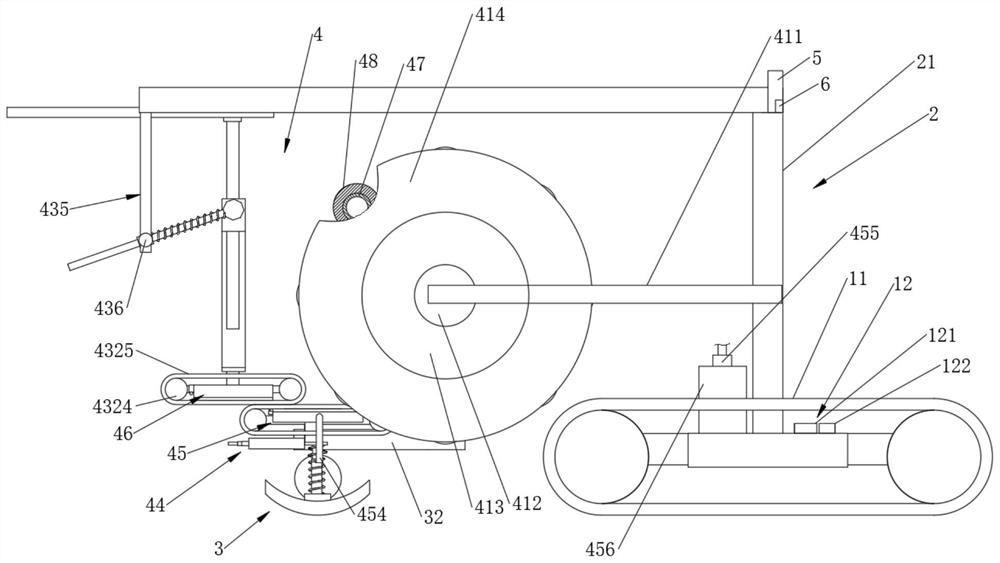

Maintenance equipment for concrete pouring

InactiveCN112160599ALaminationImprove adhesionRoads maintainenceBuilding material handlingArchitectural engineeringStructural engineering

The invention relates to the technical field of building equipment, in particular to concrete pouring maintenance equipment which comprises a cart mechanism and a film covering mechanism, the top endsof vertical rods in two L-shaped rods are rotationally connected with second rolling wheels, and one ends of transverse rods in the two L-shaped rods are rotationally connected with first rolling wheels. A first bearing sleeve and a second bearing sleeve are rotatably connected to the top ends of two bearing seat rods correspondingly, a first belt wheel is rotatably connected to the outer side wall of the second bearing sleeve, the first belt wheel is in transmission connection with a second belt wheel through a belt, a water tank is fixedly connected to the surface of the bottom plate, and awater suction pump is fixedly connected into the water tank. According to the device, the cart mechanism walks and is in transmission connection with the belt wheel II through the belt wheel I to unwind and wind a transparent film, the concrete floor is coated synchronously in the walking process, and water is scattered between concrete and the transparent film in the coating process. When the transparent film is in contact with the concrete ground, curing water is synchronously sprinkled to cure the ground.

Owner:王文磊

Metal plate film covering device with adjustment function

The invention discloses a metal plate film covering device with an adjustment function. The metal plate film covering device comprises a film covering box, the film covering box is internally providedwith a film covering cavity, a transmission cavity and a clipping cavity, wherein the transmission cavity and the clipping cavity are located below the film covering cavity, the clipping cavity is located on the right side of the transmission cavity, the front wall of the film covering cavity is rotatably provided with a rotating shaft, the rotating shaft is fixedly provided with a driving chainwheel, and the driving chain wheel is provided with a chain in an engaged manner. According to the metal plate film covering device with the adjustment function, an adjustment block is adopted to moveupwards to drive a ratchet strip to move to right to tension a tightening wheel, so that tightening of a plastic film is adjusted, metal plate cleaning before film covering is realized by adopting ascraping plate, the fact that a metal plate is intermittently stopped after being conveyed for a certain length is realized by utilizing a planetary gear system, clipping is conveniently performed, film covering on the metal plate surface is realized, the metal plate surface plastic film smoothness is improved, and time and effort for manual tensioning control are reduced.

Owner:江苏华美特金属科技有限公司

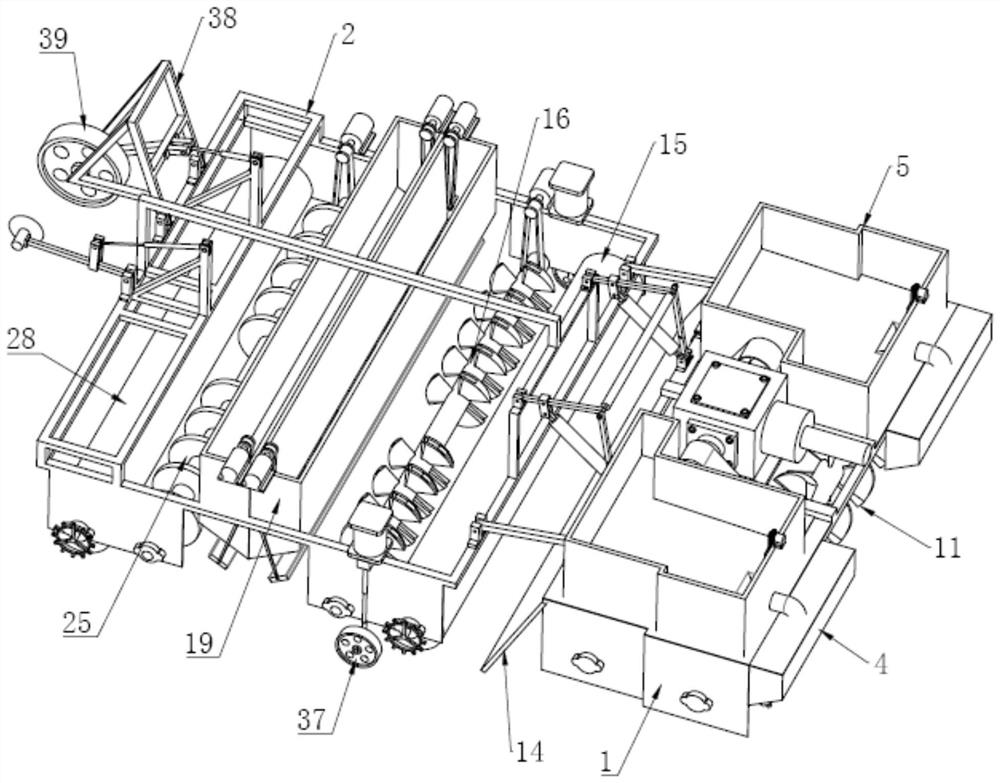

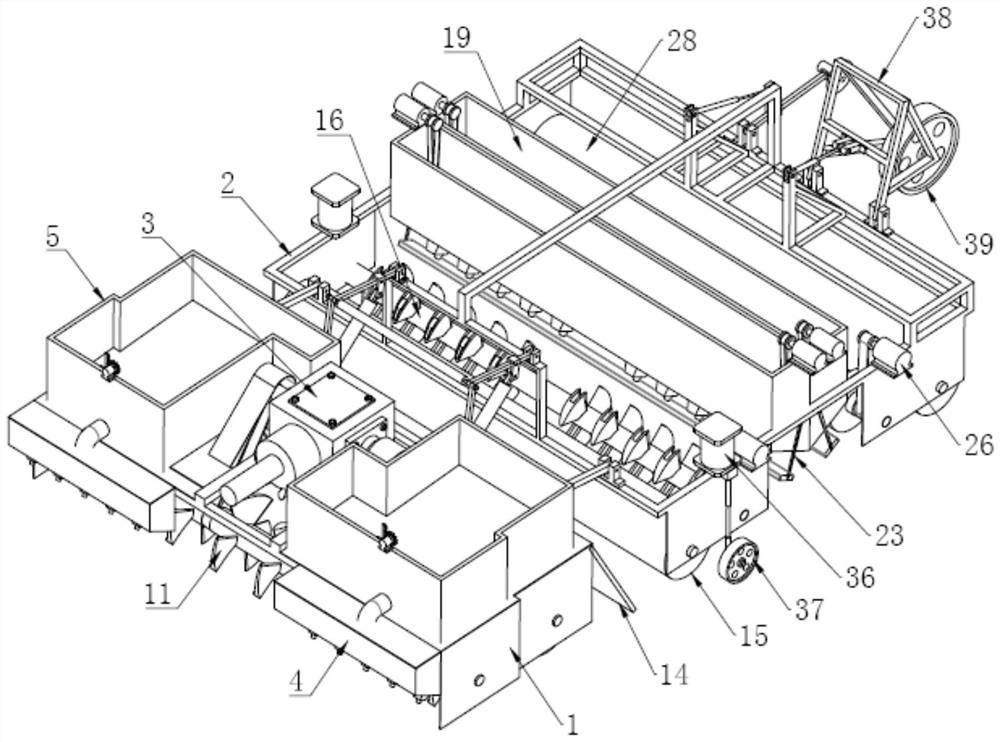

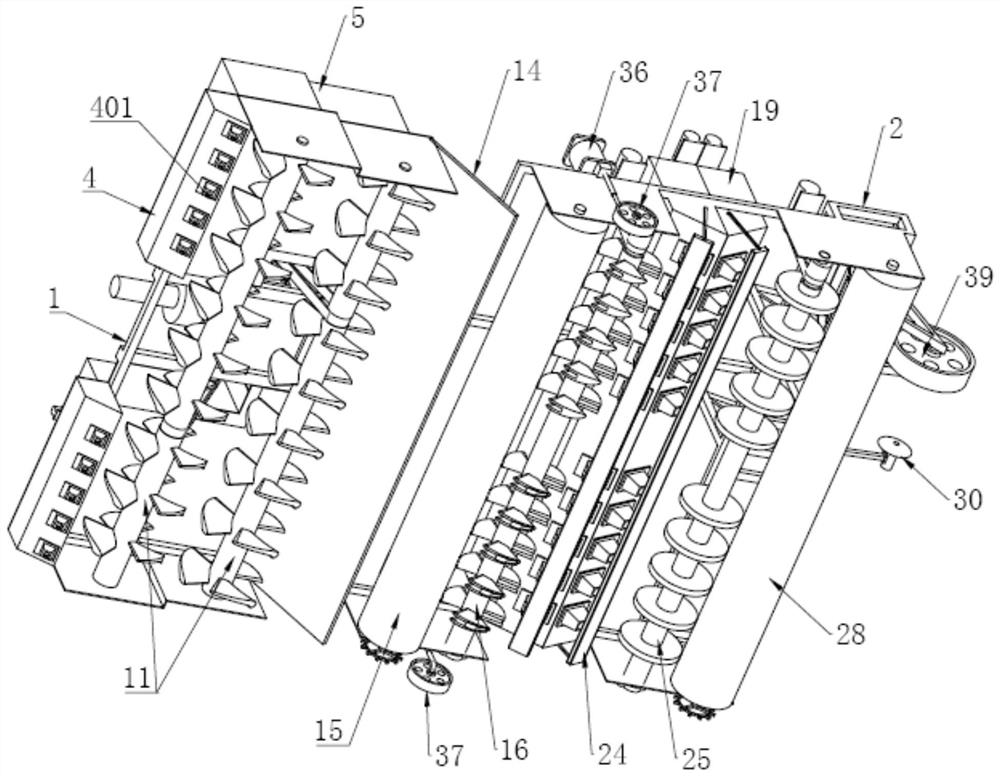

Paper tableware processing equipment

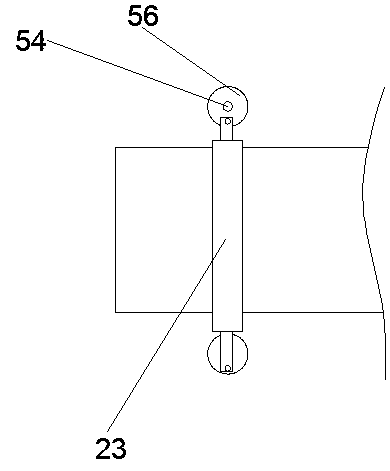

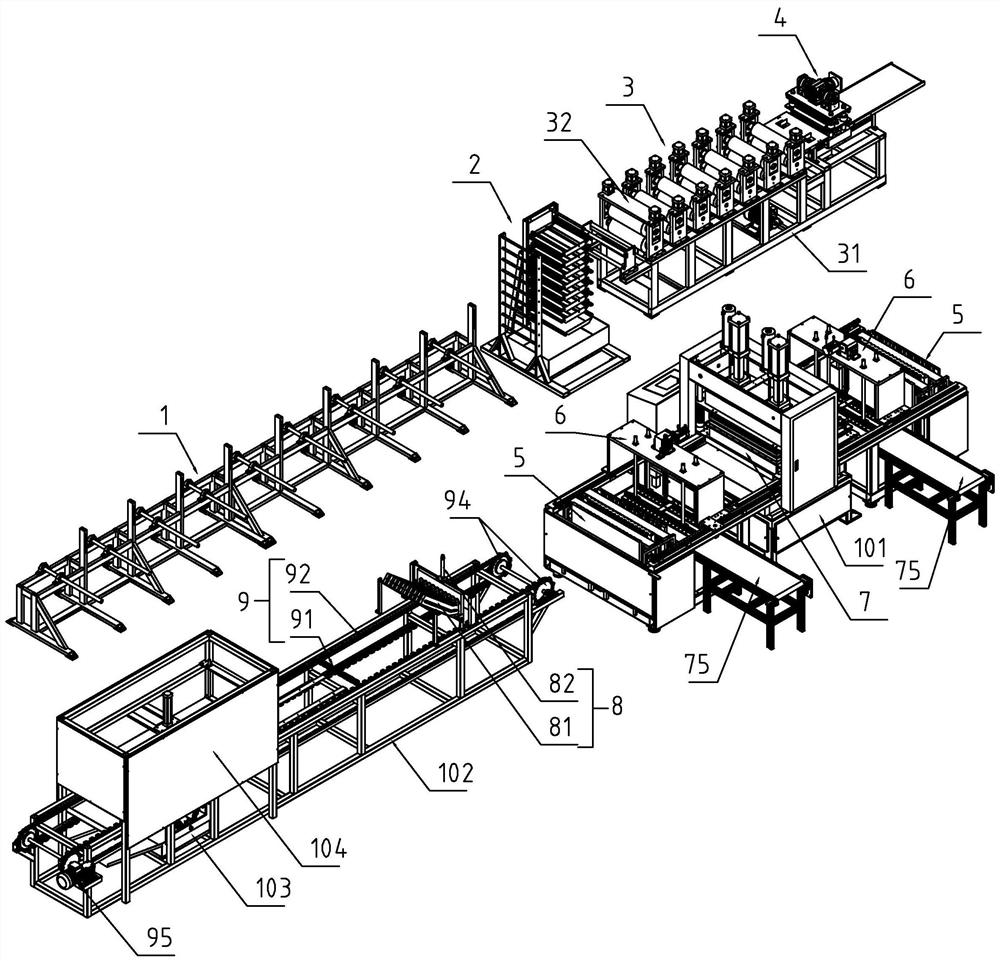

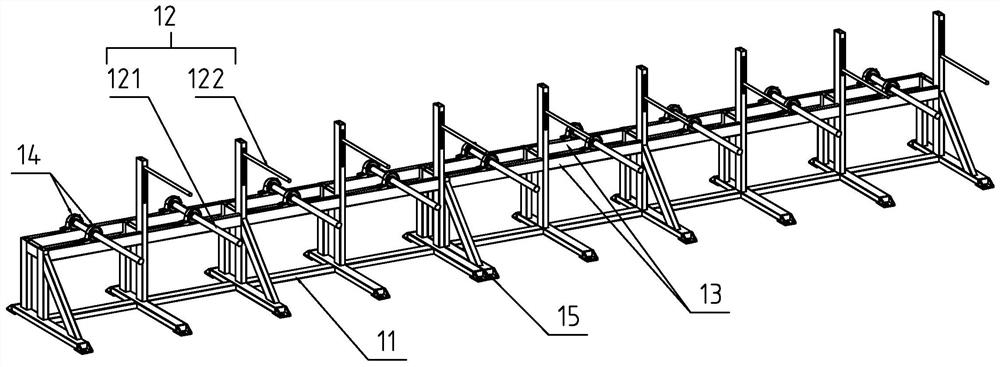

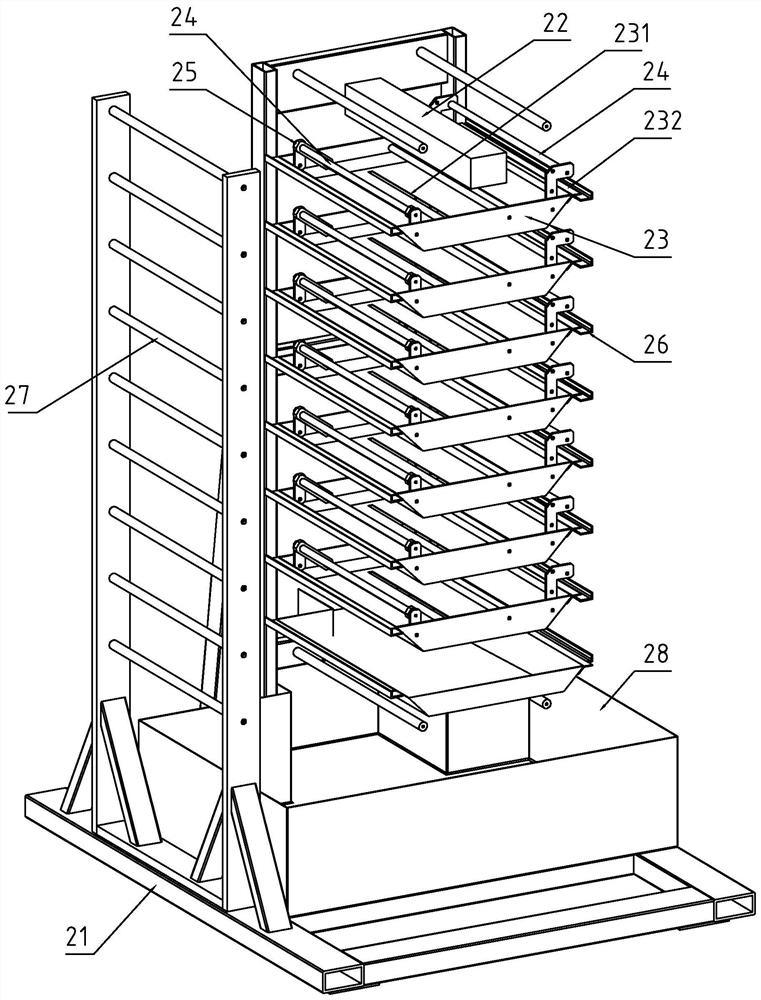

PendingCN113400714ALaminationLower energy requirementsEnvelopes/bags making machineryPaper/cardboard articlesProcess engineeringIndustrial engineering

The invention discloses paper tableware processing equipment. According to the technical scheme, the paper tableware processing equipment is characterized by comprising a forming device used for processing paper strips into paper tableware, a shaping device used for heating and shaping the paper tableware, and a laminating device used for laminating the paper tableware; the forming device comprises a discharging mechanism used for releasing multiple layers of paper strips, a gluing mechanism used for gluing the paper strips, a pressing mechanism used for pressing and forming the glued multiple layers of paper strips, and a blanking mechanism used for blanking and forming the paper strips. the shaping device comprises a molding rack, a storage bin used for storing the paper tableware, a material moving manipulator which is connected to the molding rack in a sliding mode and used for moving and taking the paper tableware, and a shaping mold used for heating and shaping the sheet-shaped paper tableware; and the laminating device comprises a laminating rack, a laminating mechanism, a drying mechanism, a feeding mechanism capable of storing and conveying the paper tableware to be laminated, and a feeding mechanism capable of driving the paper tableware to move. The paper tableware processing equipment can realize automatic processing of the paper tableware.

Owner:ZHEJIANG OUNO MASCH CO LTD

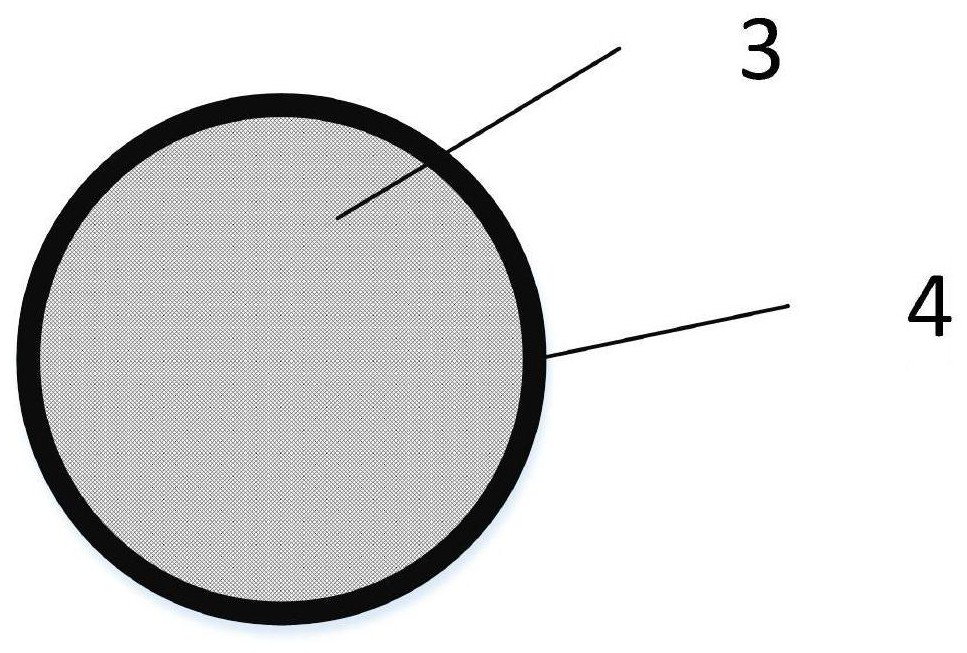

Main-grid-free and anti-subcrack battery assembly

The invention discloses a main-grid-free and anti-subcrack battery assembly. The main-grid-free and anti-subcrack battery assembly comprises main-grid-free battery pieces and copper wire meshes, wherein a plurality of transversal secondary grids are arranged on the front surfaces of the main-grid-free battery pieces; the copper wire meshes are formed by weaving a plurality of longitudinal copper wires and a plurality of transversal copper wires; the copper wire meshes cover the front surfaces of the longitudinally-arranged main-grid-free battery pieces; the copper wires of the copper wire meshes and the secondary grids of the main-grid-free battery pieces are welded at intersections to form battery strings; the plurality of battery strings are connected through bus bars into the battery assembly. The main-grid-free and anti-subcrack battery assembly uses the battery pieces without main grid structures, and the woven copper wire meshes and the secondary grids of a battery are directly intersected and welded. Through thousands of contacts between the woven copper wire meshes and the secondary grids of the battery, current conducting paths at subcrack and microcrack parts of a wafer are more optimized, so that loss caused by subcrack is greatly reduced and hot spot problems of the assembly can be greatly reduced.

Owner:SUZHOU COOP & INNO GREEN ENERGY TECHNOLOGY CO LTD

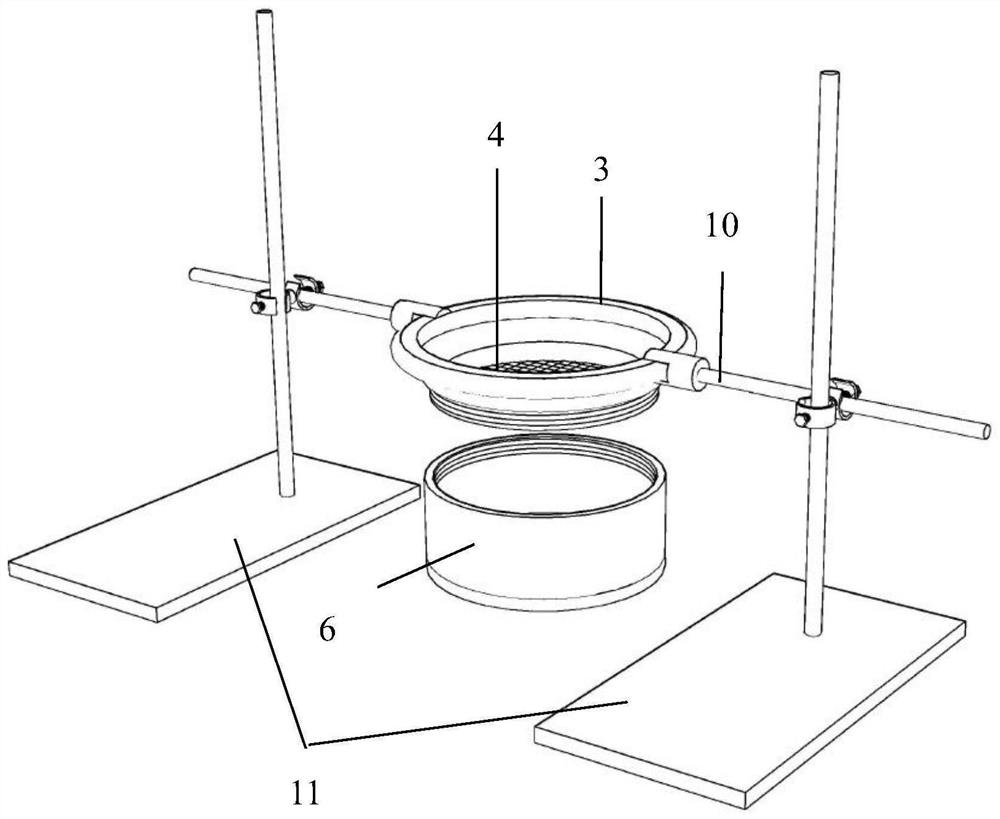

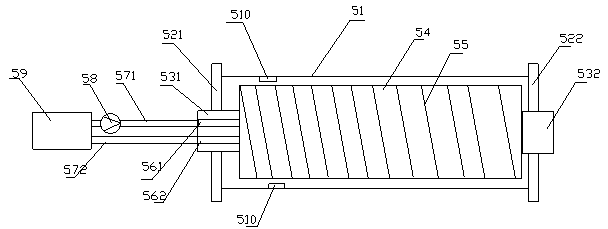

Device and method for preparing film-coated self-healing material

PendingCN112892507AImprove adsorption capacityUniform adsorptionGranule coatingOther chemical processesFilm-coated tabletFilm coating

The invention relates to the technical field of preparation of self-healing materials and film coating, and provides a device for preparing a film-coated self-healing material. The device for preparing the film-coated self-healing material comprises a detachable adsorption device and a film coating device, The device for preparing the film-coated self-healing material not only can be used for preparing the self-healing material, but also can be used for coating the prepared self-healing material. The device is simple and easy to obtain, and the investment of equipment funds for preparing the self-healing material and coating the self-healing material can be greatly reduced. Experimental results show that when the device provided by the invention is used for preparing the self-healing material, the adsorption capacity can reach 90% or above of the maximum adsorption capacity of the carrier. The film coating device provided by the invention for the self-healing material can obtain a film layer of 78.5 microns after the self-healing material is coated with a film, and ions in a self-healing material solution can be effectively prevented from being diffused.

Owner:SHENZHEN UNIV

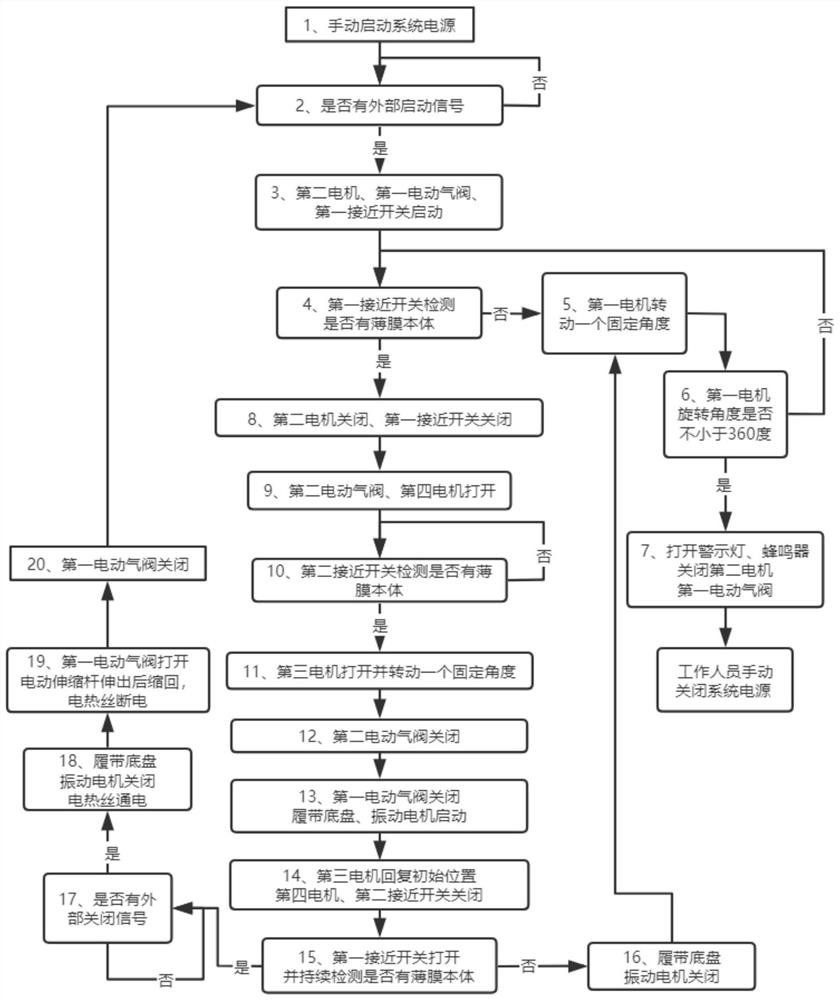

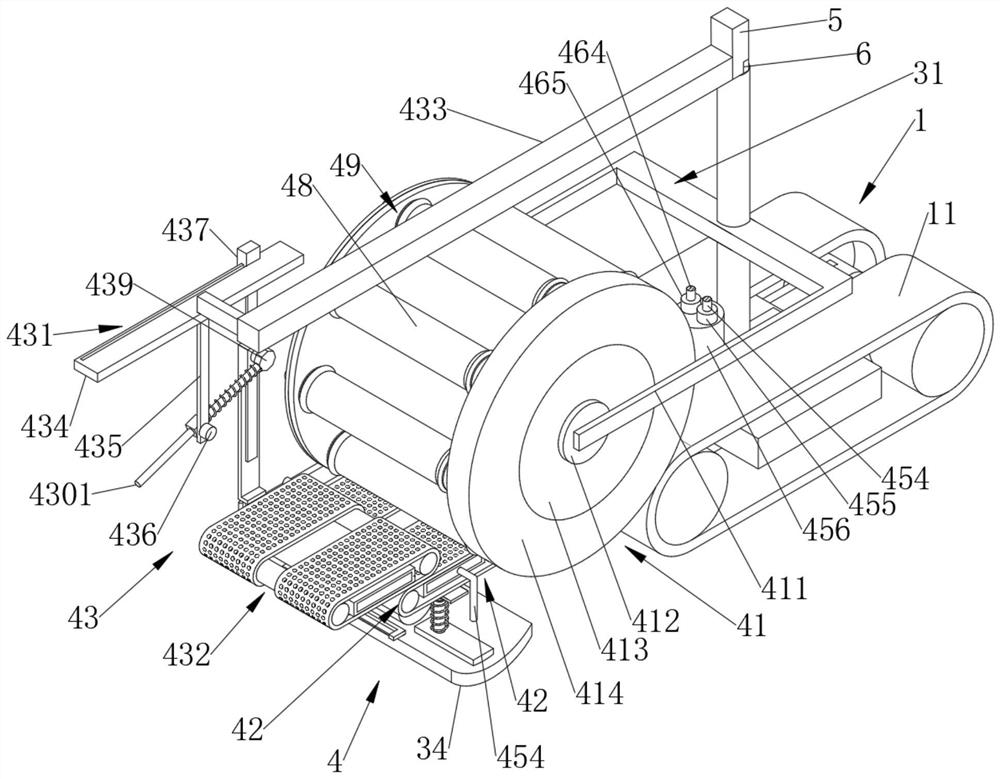

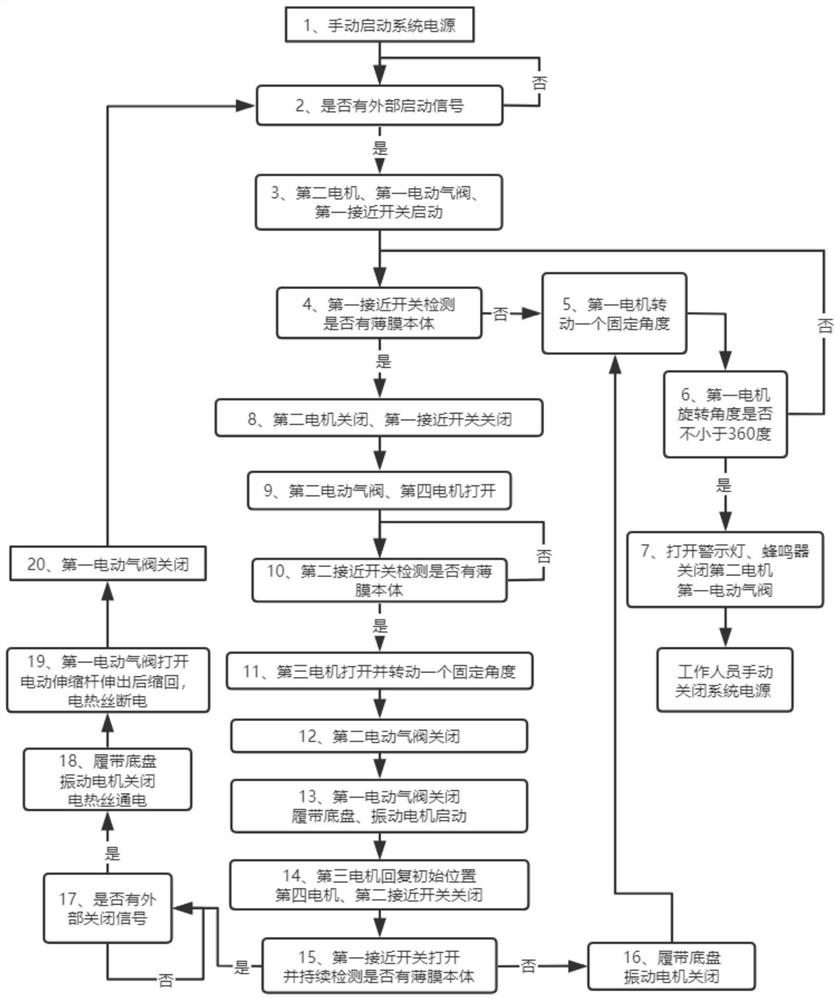

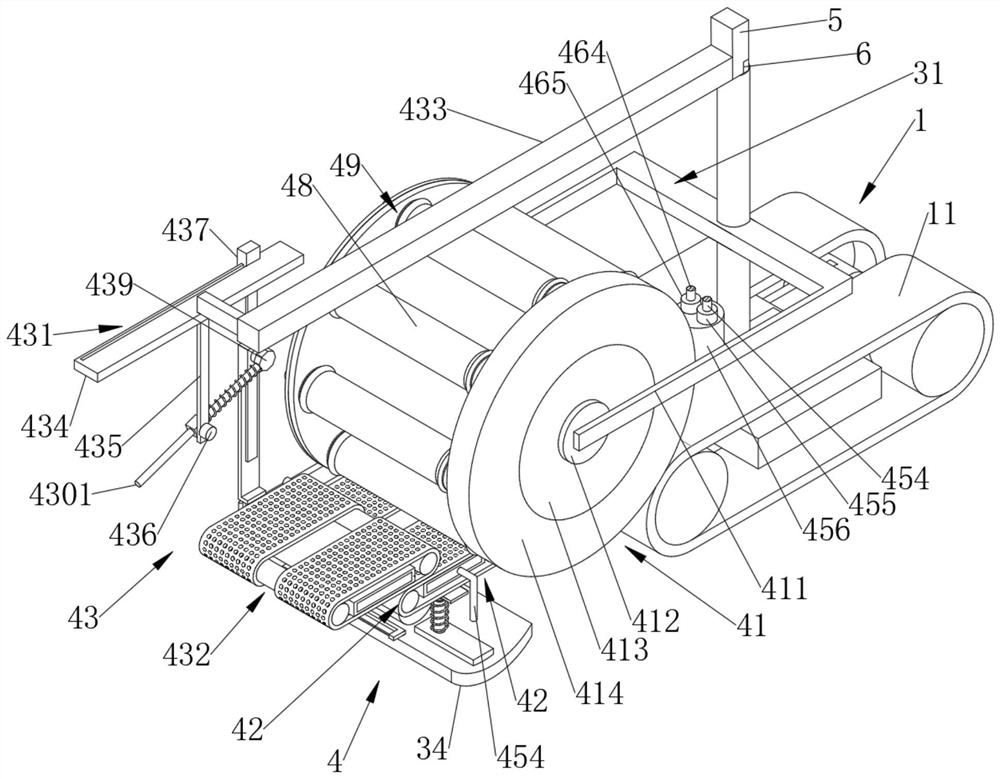

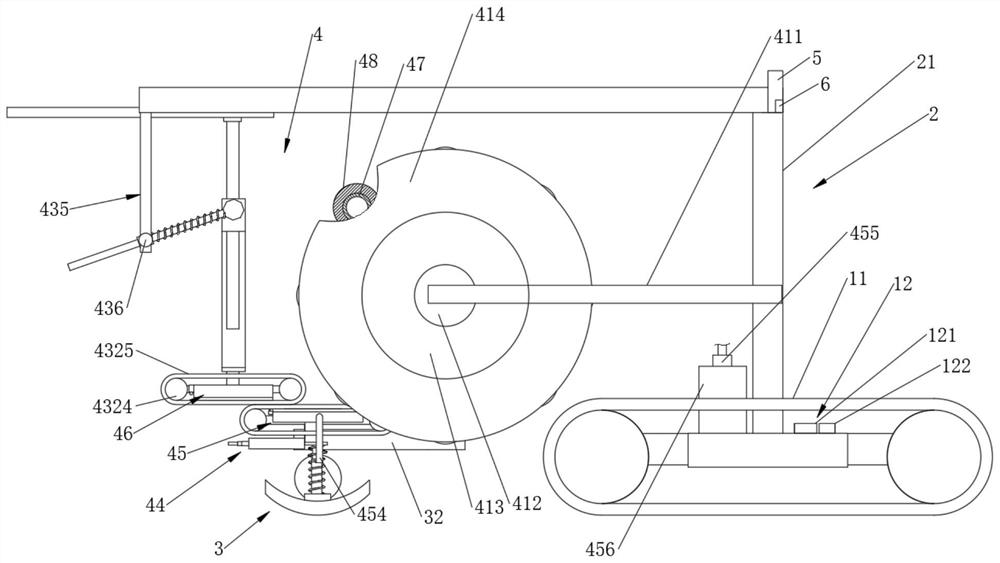

Concrete curing and film covering device for building construction in summer and using method

ActiveCN113494189AReduce the impactEasy to realize light collectionBuilding material handlingArchitectural engineeringCovers (device)

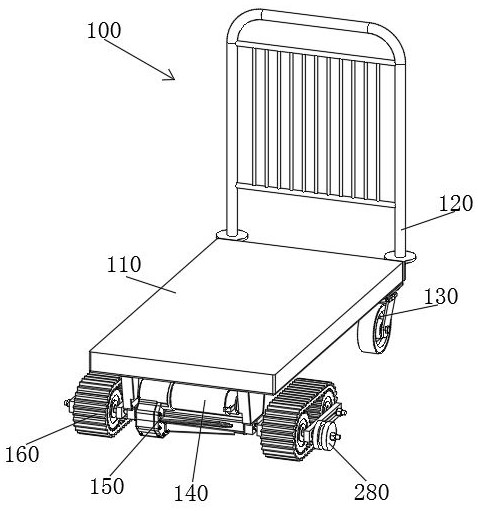

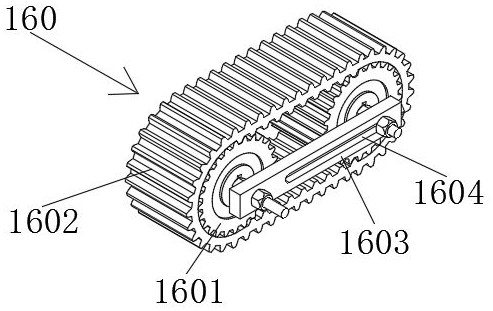

The invention discloses a concrete curing and film covering device for building construction in summer and a using method, and relates to the technical field of concrete film covering devices. The device is technically characterized by comprising a driving mechanism, the driving mechanism comprises a crawler chassis and a control core, the upper portion of the crawler chassis is fixedly connected with a support and the control core, the support comprises a vertical rod, the bottom of the vertical rod is fixedly connected to the crawler chassis, the vertical rod is fixedly connected with a vibration flattening mechanism and a film covering mechanism, and the film covering mechanism comprises a film feeding mechanism, a film tearing mechanism, a film laying mechanism and a film cutting mechanism. The concrete curing and film covering device has the advantages that the automation degree of the whole device is improved through mutual cooperation of multiple mechanisms and the control core, the requirement of the whole device for the work content needing to be executed by people is reduced while concrete film covering is achieved, and the work efficiency is improved.

Owner:CHINA RAILWAY CONSTR ENG GROUP +1

Graphene coated tungsten-based hot cathode and preparation method thereof

PendingCN112117170AImprove launch performanceImprove stabilityDischarge tube/lamp detailsThermionic cathode manufactureGraphiteSingle layer graphene

The graphene coated tungsten-based hot cathode comprises a graphene layer and a tungsten-based cathode layer, the upper surface of the tungsten-based cathode layer is coated with the graphene layer, and a lamp filament is arranged below the tungsten-based cathode layer. The preparation method comprises the following steps: (1) preparing a tungsten substrate with a smooth surface; (2) coating the tungsten substrate with a graphene layer; and (3) assembling the cathode heater assembly. The invention provides a metal coated tungsten-based hot cathode which is simple in structure, easy to prepareand excellent in emission performance. Simulation shows that the surface work function of the metal coated tungsten-based hot cathode is 1.745 eV under the condition that the surface of the metal coated tungsten-based hot cathode is coated with single-layer graphene.

Owner:SOUTHEAST UNIV

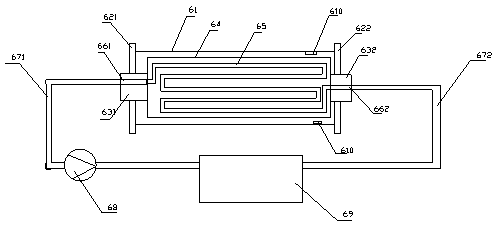

Circulating cooling film feeding machine

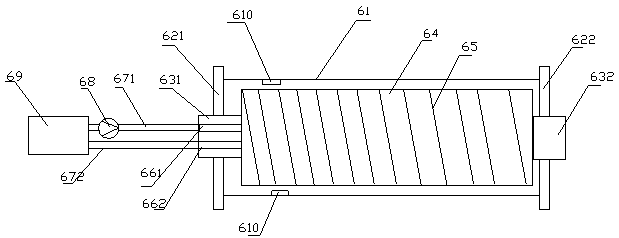

The invention relates to a circulating cooling film feeding machine. The film feeding machine comprises a paper feeding roller, a film feeding roller and a pressing roller assembly which are arrangedin sequence in the roll paper advancing direction; the paper feeding roller is used for winding roll paper, and the film feeding roller is used for winding roll film; a water pipe comprises a plurality of straight parts arranged in the roller axial direction and connecting parts used for making the ends of every two adjacent straight parts communicated, and the water pipe extends to a second end from a first end of an inner pipe, then extends to the first end after bending from the second end, and is communicated with a water outlet of the second end after bending several times. According to the circulating cooling film feeding machine, an upper pressing roller and a lower pressing roller are used for pressing the film on the roll paper to achieve film covering; a collecting roller is provided with the cooling water pipe in an inner roller body, and when the roller temperature is high, cooling water can be introduced into the water pipe for cooling.

Owner:苏州古柏利电子科技有限公司

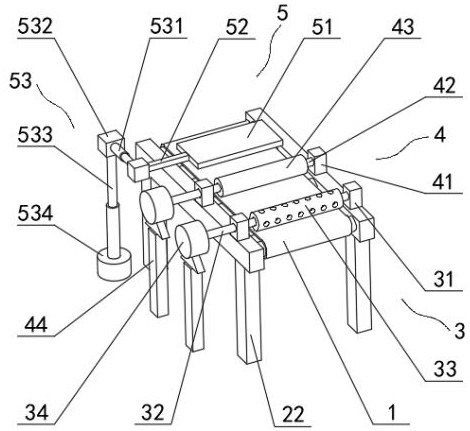

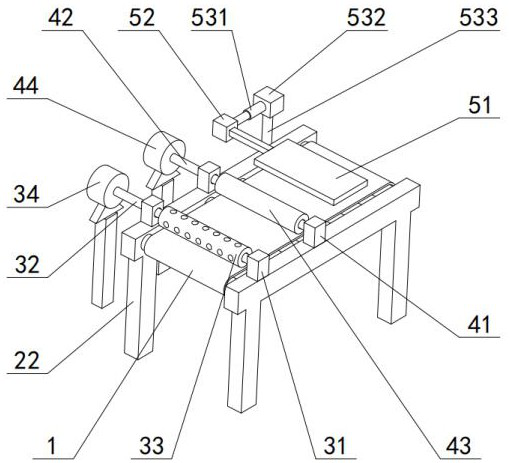

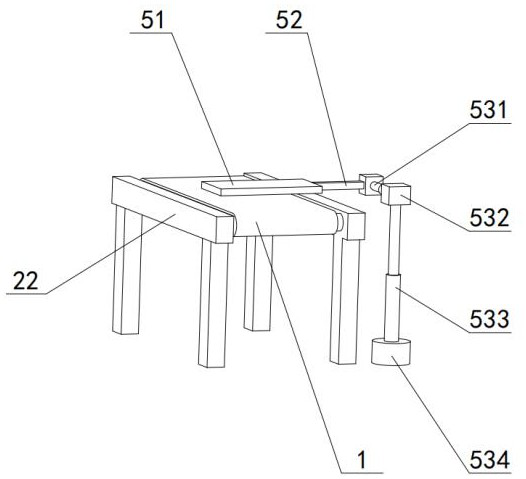

Steel plate coating device for insulating plate production line

InactiveCN112238599AAchieve wipeAvoid affecting the coating effectCleaning using toolsFlat articlesEngineeringManufacturing line

The invention discloses a steel plate coating device for an insulating plate production line and relates to the field of insulating plates. The steel plate coating device comprises a worktable, an erasing mechanism and a coating mechanism, wherein supporting legs are fixed to positions, close to four side corners, of the bottom of the worktable; a moving mechanism is arranged on the worktable andtwo clamping plates are arranged on the top of the moving mechanism, and the moving mechanism drives the two clamping plates rotatably to move oppositely or reversely; the erasing mechanism is arranged on the top of the worktable and erases the surface of the steel plate placed on the top of the worktable in a sliding manner; and the coating mechanism is arranged on the top of the worktable according to a demand to coat the steel plate. By placing the steel plate on the worktable, a rotating plate is rotated, a screw I and a screw II further rotate along with the rotating plate, and two supporting rods will drive the clamping plates thereon to move oppositely or reversely till the steel plate is located between the two clamping plates to clamp the steel plate, so that the steel plate is fixed to the worktable.

Owner:衡阳凌云特种材料有限公司

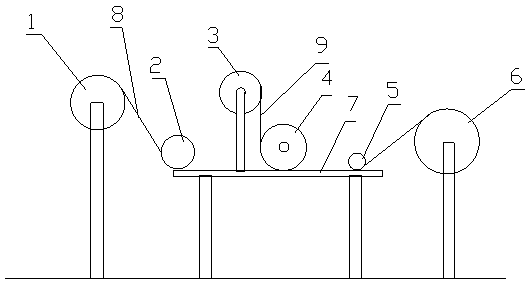

Film feeding machine with water tank

InactiveCN108792039ALaminationSave waterLamination ancillary operationsWrapping material feeding apparatusRolling paperWater resources

The invention relates to a film feeding machine with a water tank. A film laminator comprises a paper feeding roller, a film feeding roller and a compression roller assembly which are successively arranged along the advancing direction of roll paper. The paper feeding roller is used for winding the roll paper; the film feeding roller is used for winding a roll film; the compression roller assemblycomprises an upper compression roller and a lower compression roller which are arranged up and down; the roll paper and the roll film pass between the upper compression roller and the lower compression roller. The film laminator also comprises a material receiving roller. When the temperature measured by a temperature sensor is lower than a set value, operation is stopped. According to the film feeding machine with the water tank provided by the invention, a film is pressed to the roll paper by means of the upper compression roller and the lower compression roller to be laminated; as a cooling water tube is arranged in an inner roller, when the temperature of the roller is relatively high, the cooling water tube can introduce cooling water into a water pipe for cooling. Meanwhile, the used cooling water is collected to the water tank to be recycled, so that the water resource is saved.

Owner:苏州古柏利电子科技有限公司

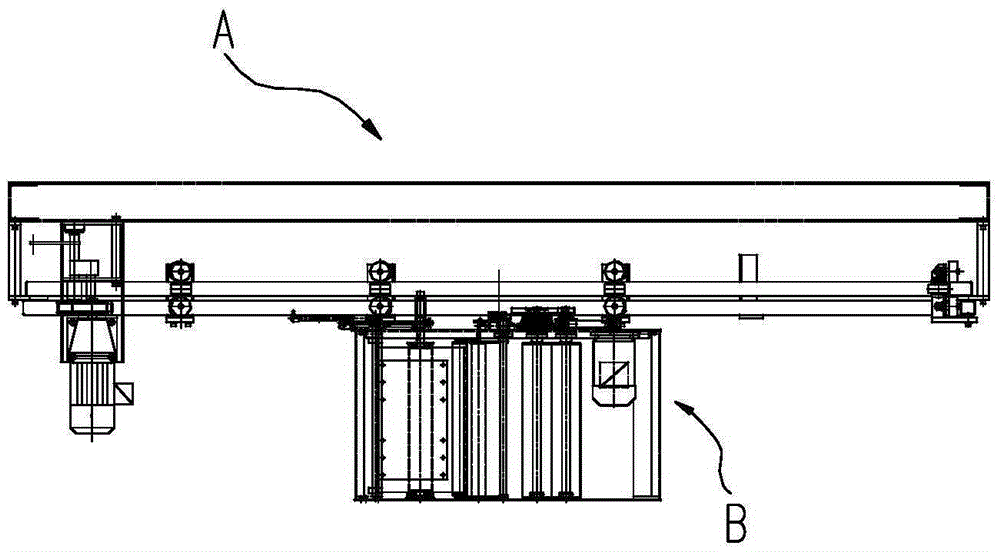

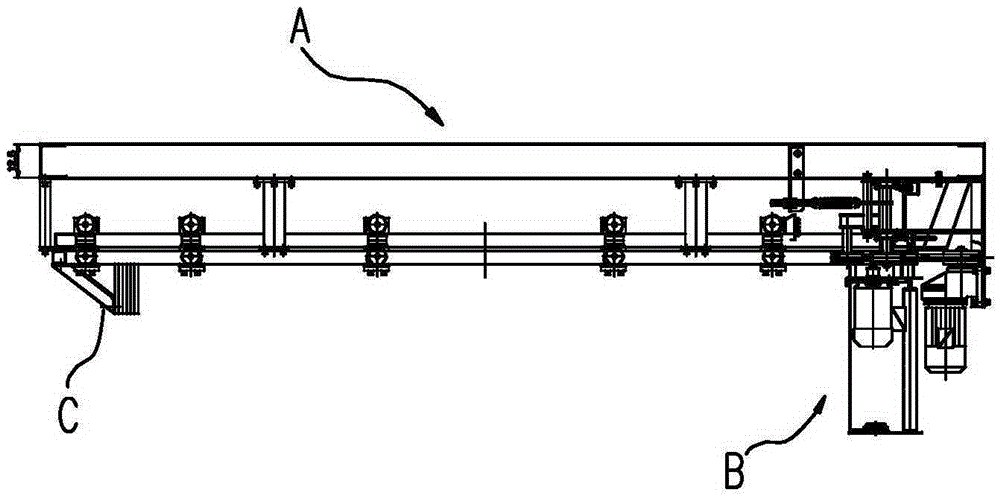

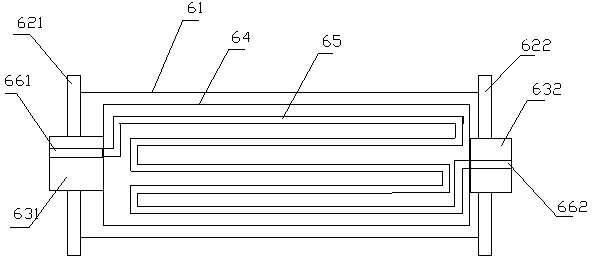

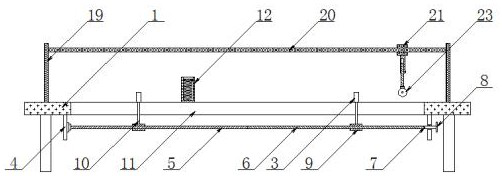

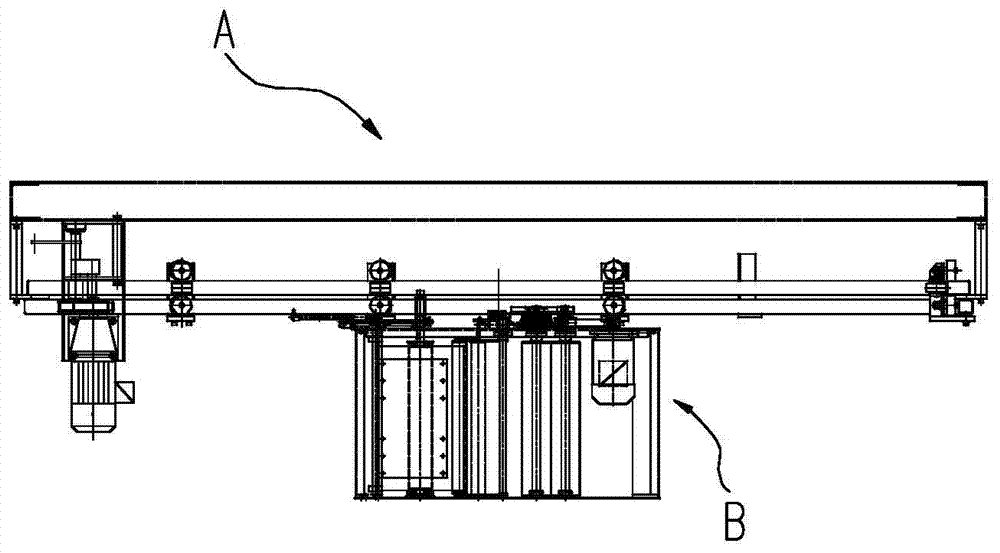

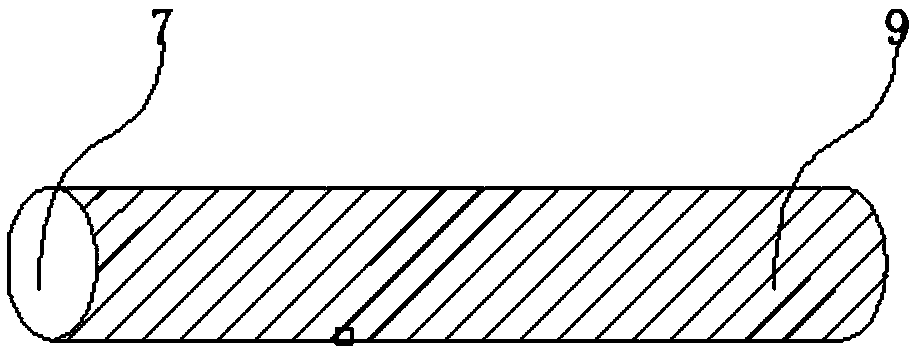

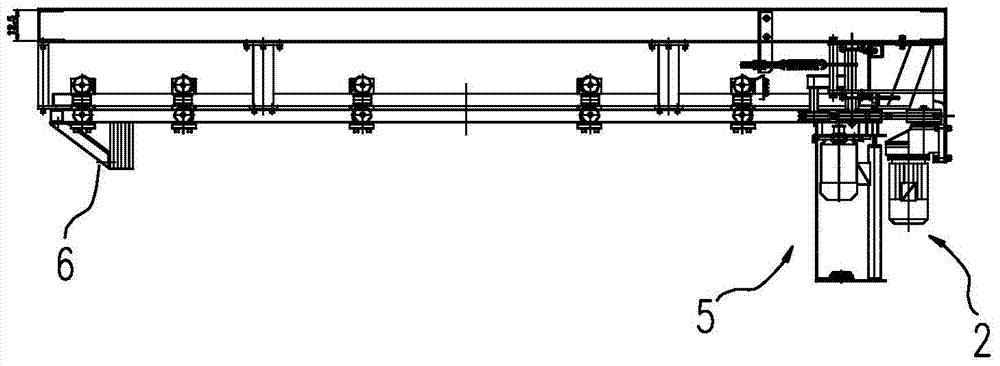

Transmission device used for ring rail type laminating machine

The invention discloses a transmission device used for a ring rail type laminating machine. The transmission device comprises a platform rack. A connecting hanging frame convenient to fix is arranged on the lower portion of the platform rack. The transmission device further comprises a driving device arranged on the lower portion of the platform rack, a rail device fixedly connected to the lower side of the platform rack through the connecting hanging frame, and an electricity taking device arranged on the rail device. A cooperative relation that an object located in a laminating station is laminated in the rotation process of the rail device is formed by the driving device and the rail device. The transmission device further comprises a control mechanism. The control mechanism comprises a PLC electrically connected with the driving device and the rail device, and a touch screen electrically connected to the output end of the PLC and facilitating manual operation. The transmission device is applied to a packing device and is combined with a film releasing device, so that energy consumption is effectively reduced, the packing speed is increased, labor cost is reduced, and production efficiency is improved.

Owner:HEFEI GENERAL MACHINERY RES INST

Film feeding machine

The invention relates to a film feeding machine. The film feeding machine comprises a paper feeding roller, a film feeding roller and a pressing roller which are arranged in sequence, the paper feeding roller is used for winding coiled paper, the film feeding machine further comprises a first guide roller, and the first guide roller is used for guiding the roll paper of the paper feeding roller toa pressing plate; the film feeding machine further comprises a second guide roller, the second guide roller is positioned behind the pressing roller and is positioned on the upper side of the pressing plate, the second guide roller is used for guiding a finished product to a material receiving roller; the second guide roller comprises an outer roller, an inner roller arranged in the outer roller,a first end cover and a second end cover, the first end cover and the second end cover are arranged at the two ends of the outer roller cylinder, one end of the cooling water pipe communicates withthe water inlet, and the other end of the second guide roller communicates with a water outlet; and the second guide roller further comprises a water tank, the water tank communicates with the waterinlet through a first water conveying pipe, and the water tank communicates with the water outlet through a second water conveying pipe.

Owner:苏州古柏利电子科技有限公司

One-in-one-out snorkeling mask

The invention discloses a single-inlet and single-out snorkeling mask, which includes a transparent mask body, a silicone mask body and a double-track breathing tube; An exhalation cavity, an inhalation cavity is formed between the outer surface of the silicone mask body and the inner surface of the transparent mask body, and the silicone mask body is provided with a first one-way valve plate that makes the inhalation cavity communicate with the exhalation cavity in one direction; The double-track breathing tube is arranged on the transparent mask body, the double-track breathing tube has an inhalation channel and an exhalation channel, and the tail end of the exhalation channel is provided with a second one-way valve plate. By adopting a double-track breathing tube and cooperating with the first one-way valve and the second one-way valve to form a single-inlet and single-outlet circulation structure, the intake and outlet are completely separated, so that there will be no waste and fresh air Convergence can solve shortness of breath and stuffy heart, and there is no need to worry about the exhaust gas being repeatedly inhaled and causing physical harm.

Owner:SHENZHEN CP LINK ELECTRONICS CO LTD

A protective film coating device for a flexible circuit board

ActiveCN113225930BFilm coating is effectiveAvoid offsetNon-metallic protective coating applicationFlexible circuitsTransmission belt

The invention relates to the technical field of flexible circuit boards, and discloses a protective film coating device for flexible circuit boards. Avoid the flexible circuit board being shifted by vibration while being transferred with the transmission belt, and ensure that the flexible circuit board can be effectively coated. While fixing the flexible circuit board, it triggers the cleaning and film covering operations to increase the linkage between the structures, which is convenient to operate and has a high degree of automation. , using the pressure to automatically clean and collect the dust on the surface of the flexible circuit board, avoiding the existence of dust, reducing the adhesion between the circuit board and the protective film, and enhancing the coating effect. After cleaning, it will automatically spray air on the protective film to make the protective film Adhesive to flexible circuit boards to achieve lamination.

Owner:SHENZHEN CITY THREE GOLDS PRECISE CIRCUIT TECH

Film feeding machine with cooling water tank

InactiveCN108466861ALaminationPlay a role in coolingDomestic cooling apparatusLighting and heating apparatusWater resourcesPulp and paper industry

The invention relates to a film feeding machine with a cooling water tank. The film feeding machine comprises a paper feeding roller, a film feeding roller and a press roller assembly which are sequentially arranged in an advancing direction of roll paper, wherein the paper feeding roller is used for winding the roll paper; the film feeding roller is used for winding a roll film; the press rollerassembly comprises an upper press roller and a lower press roller arranged up and down; and the roll paper and the roll film pass through a position between the upper press roller and the lower pressroller. The film feeding machine further comprises a receiving roller. According to the film feeding machine with the cooling water tank, a thin film is pressed on the roll paper by utilizing the upper press roller and the lower press roller, so that film coating is realized; and the receiving roller is provided with a cooling water pipe, when the temperature of a roller is higher, cooling water is fed to play a role in cooling, and meanwhile, the cooling water is collected into the water tank after being used so as to be recycled, so that the water resource is saved.

Owner:苏州古柏利电子科技有限公司

Flexible circuit board protective film coating device

ActiveCN113225930AIncrease linkageEasy to operateNon-metallic protective coating applicationComposite materialFilm coating

The invention relates to the technical field of flexible circuit boards, and discloses a flexible circuit board protective film coating device. The device comprises a shell, and the outer side of the shell is movably connected with a conveying belt; and the flexible circuit board is automatically clamped, the position of the flexible circuit board is adjusted, it is avoided that the flexible circuit board shifts under the vibration effect while being transferred along with the transmission belt, and it is guaranteed that the flexible circuit board can be effectively coated with a film. While the flexible circuit board is fixed, cleaning and film covering operations are triggered, linkage between structures is increased, operation is convenient and fast, and the automation degree is high; dust on the surface of the flexible circuit board is automatically cleaned and collected through the combined action of an air injection mechanism, a connecting pipe, a suction tool and a piston and the action of pressure intensity, so the adhesion between the circuit board and the protective film is prevented from being reduced due to the existence of dust, and the film covering effect is enhanced; and air is automatically sprayed to the protective film after cleaning is completed, and the protective film is bonded with the flexible circuit board, so film covering is achieved.

Owner:SHENZHEN CITY THREE GOLDS PRECISE CIRCUIT TECH

A busbar-free anti-crack battery assembly

The invention discloses a main-grid-free and anti-subcrack battery assembly. The main-grid-free and anti-subcrack battery assembly comprises main-grid-free battery pieces and copper wire meshes, wherein a plurality of transversal secondary grids are arranged on the front surfaces of the main-grid-free battery pieces; the copper wire meshes are formed by weaving a plurality of longitudinal copper wires and a plurality of transversal copper wires; the copper wire meshes cover the front surfaces of the longitudinally-arranged main-grid-free battery pieces; the copper wires of the copper wire meshes and the secondary grids of the main-grid-free battery pieces are welded at intersections to form battery strings; the plurality of battery strings are connected through bus bars into the battery assembly. The main-grid-free and anti-subcrack battery assembly uses the battery pieces without main grid structures, and the woven copper wire meshes and the secondary grids of a battery are directly intersected and welded. Through thousands of contacts between the woven copper wire meshes and the secondary grids of the battery, current conducting paths at subcrack and microcrack parts of a wafer are more optimized, so that loss caused by subcrack is greatly reduced and hot spot problems of the assembly can be greatly reduced.

Owner:SUZHOU COOP & INNO GREEN ENERGY TECHNOLOGY CO LTD

Anti-counterfeit label film covering and leveling device for intelligent logistics

InactiveCN113788353AAchieve levelingGuaranteed flatnessArticle feedersArticle deliveryLogistics managementMechanical engineering technology

The invention relates to the technical field of mechanical engineering, in particular to an anti-counterfeit label film covering and leveling device for intelligent logistics. Label paper is placed on a conveying belt, so that the glued label paper can be conveyed to the position near a film covering roller, at the moment, a rotating shaft is rotated, and the film covering roller rotates; and a film on the film covering roller can be in contact with the label paper with glue on the surface, the label paper continues to horizontally move while the film covering roller rotates, film covering of the label paper is achieved, and a movable block is driven by a driving component to move when the label paper after film covering moves to a position near a leveling plate so that the leveling plate moves. Then the label paper and a covering film can be leveled, and the flatness of the surface of the label paper after the film is attached is guaranteed through leveling of the label paper and the covering film.

Owner:重庆源融标签印刷有限公司

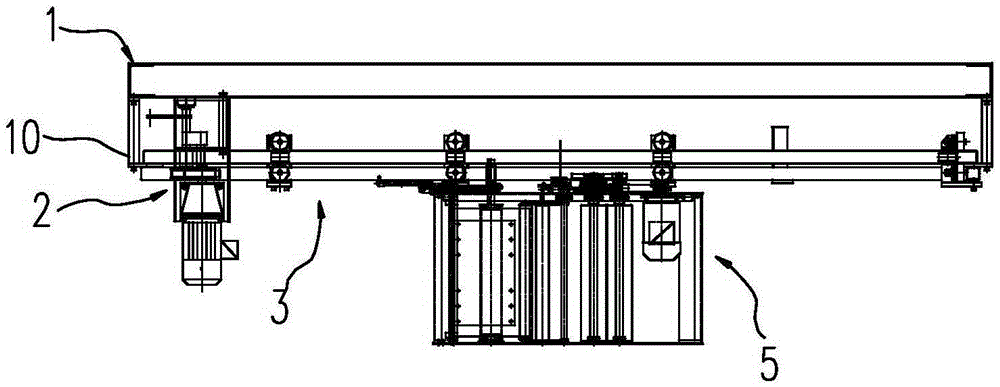

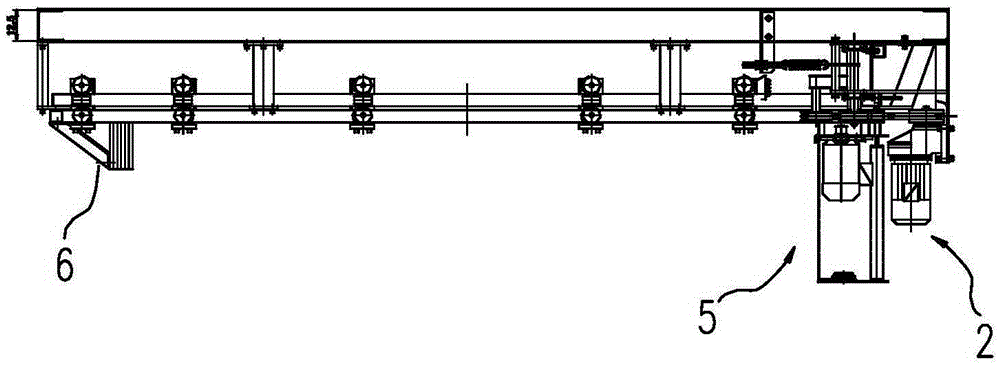

A ring track laminating machine

ActiveCN105398592BLaminationWrapping material feeding apparatusWeb rotation wrappingEngineeringEnergy consumption

The invention discloses a circular track type film laminating machine. The circular track type film laminating machine comprises a transmission device and a film feeding control device which achieve automatic film laminating. The film feeding control device is fixed to the transmission device and performs rotational motion along with the transmission device. The transmission device comprises a platform rack and further comprises a driving device, a track device and a power picking device, wherein connecting hangers convenient to fix are disposed under the platform rack; the driving device is mounted on the lower portion of the platform rack; the track device is fixedly connected to the lower side of the platform rack through the connecting hangers; the power picking device is disposed on the track device. The film feeding control device comprises a rack and further comprises a film storing mechanism and a film feeding mechanism which are fixedly arranged on the rack and sequentially connected, and a film is made to sequentially pass through the film storing mechanism and the film feeding mechanism to be delivered to a film clamping rod. During film laminating, an object does not rotate, and a film laminating mechanism rotates, so that the needed driving force is greatly reduced and the energy consumption is decreased. Meanwhile, the film feeding control device can make the film keep tensioned to a certain degree all the time, so that the film is not tightly tensioned and loosened, and the automation degree is high.

Owner:HEFEI GENERAL MACHINERY RES INST

Film mulching device for metal inner wall and film mulching method

The invention discloses a metal inner wall laminating device, which comprises a power supply, wherein the power supply is an alternating current, a coil electrically connected with the power supply through a conductor, a cooling device arranged on the axial or radial side of the coil, a mulching film and a deformable film mulching module. The mulching method of the metal inner wall mulching deviceincludes the following steps: step one: changing the shape of the film mulching module to match the shape of the metal cavity; step two: covering or rolling the covering film on the surface of the film mulching module; step three: filling the film mulching module into the metal cavity, placing the metal to be coated through the enclosed space formed by the coil, and placing the film mulching module in the middle of the coil; step four: turning on the alternating current, starting the device and heating the metal; step five: starting the cooling device, cooling and taking out the film mulchingmodule. The inner wall of the metal can be conveniently and rapidly coated with the adoption of the film mulching device.

Owner:FOSHAN GAOMING XILUO TECH CO LTD

A transmission device for a ring-rail laminating machine

The invention discloses a transmission device used for a ring rail type laminating machine. The transmission device comprises a platform rack. A connecting hanging frame convenient to fix is arranged on the lower portion of the platform rack. The transmission device further comprises a driving device arranged on the lower portion of the platform rack, a rail device fixedly connected to the lower side of the platform rack through the connecting hanging frame, and an electricity taking device arranged on the rail device. A cooperative relation that an object located in a laminating station is laminated in the rotation process of the rail device is formed by the driving device and the rail device. The transmission device further comprises a control mechanism. The control mechanism comprises a PLC electrically connected with the driving device and the rail device, and a touch screen electrically connected to the output end of the PLC and facilitating manual operation. The transmission device is applied to a packing device and is combined with a film releasing device, so that energy consumption is effectively reduced, the packing speed is increased, labor cost is reduced, and production efficiency is improved.

Owner:HEFEI GENERAL MACHINERY RES INST

A kind of multifunctional machine for cultivating fertilizer and seeding film

ActiveCN112385339BGuaranteed smoothMeet the needs of useSpadesAgricultural machinesSeederAgricultural engineering

The invention belongs to the technical field of agricultural machinery, and provides a multifunctional integrated machine for fertilizing, seeding and filming, which includes a fertilizing rotary tiller frame and a sowing film-covering frame connected to the fertilizing rotary tiller frame through a vibration-damping connection mechanism; The tiller frame is provided with a reducer for connecting with the traction machinery and connected by transmission. One end of the fertilization rotary tillage frame is provided with a fertilization bin, and the bottom of the fertilization bin is provided with a fertilization port. Rotary tillage rollers connected by transmission; the seeding and covering frame is successively equipped with a soil pressing roller, a digging roller, a seeder, a soil covering roller and a film covering roller along the direction away from the fertilization rotary tillage frame. Both the roller and the laminating roller are rotatably mounted on the sowing and laminating frame, the seeder is fixedly mounted on the sowing and laminating frame, and the bottom of the seeder has two rows of sowing openings arranged obliquely. The invention can realize the integrated automatic operation of fertilization, rotary tillage, leveling, digging, sowing, soil filling and film covering, and the operation efficiency and effect are greatly improved.

Owner:WEIFANG VOCATIONAL COLLEGE

Concrete curing and coating device for summer building construction and its application method

ActiveCN113494189BEasy to realize light collectionLaminationBuilding material handlingArchitectural engineeringFilm-coated tablet

The invention discloses a concrete curing and coating device for building construction in summer and a use method thereof, and relates to the technical field of concrete coating devices. Its technical points are: including the driving mechanism, the driving mechanism includes the crawler chassis and the control core, the upper part of the crawler chassis is fixedly connected with the bracket and the control core, the bracket includes a vertical pole, the bottom of the vertical pole is fixedly connected with the crawler chassis, and the vertical poles are respectively fixedly connected with The vibrating mechanism, the laminating mechanism, and the laminating mechanism include a film feeding mechanism, a tearing mechanism, a film laying mechanism, and a film cutting mechanism. The advantage of the present invention is that the present invention improves the degree of automation of the entire device by adopting the mutual cooperation of multiple mechanisms and control cores, and reduces the work content requirements of the entire device for people to perform while realizing film coating on the concrete, and improves the efficiency of the entire device. work efficiency.

Owner:CHINA RAILWAY CONSTR ENG GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com