A busbar-free anti-crack battery assembly

A technology of battery components and hidden cracks, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the conversion efficiency of cells, reducing the overall efficiency, and component failure, so as to achieve loss reduction, hot spot reduction, and light shading The effect of area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention includes battery sheet without main grid and copper wire network.

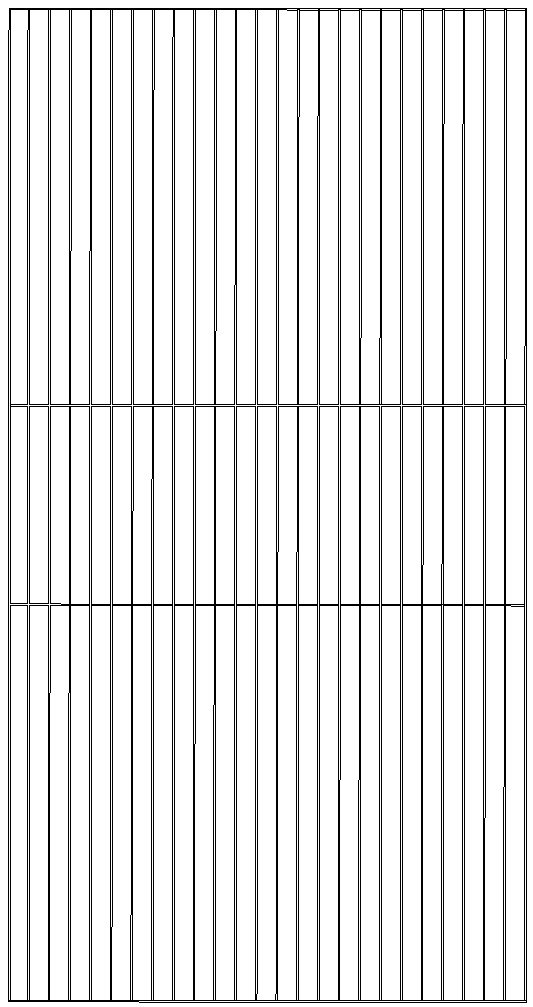

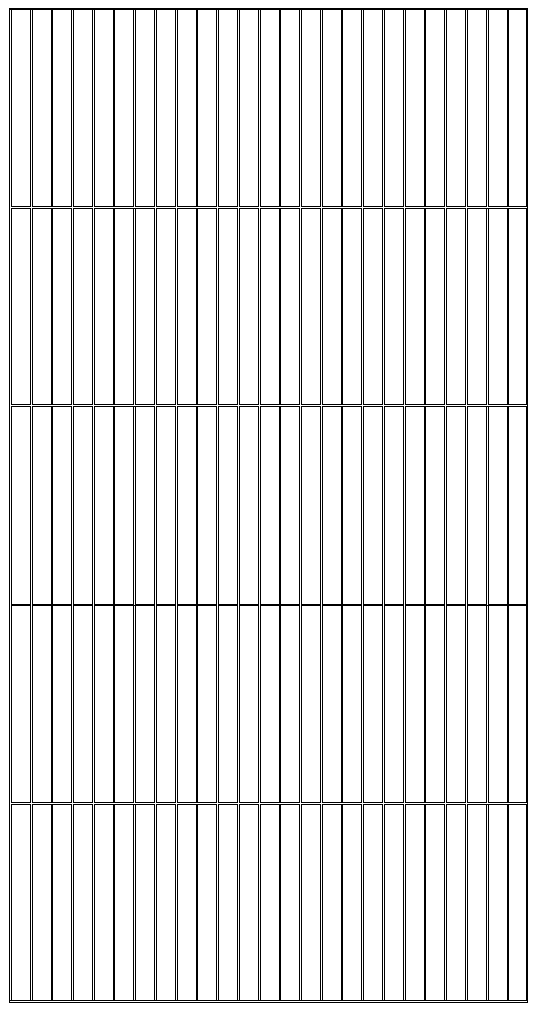

[0030] figure 1 is a schematic diagram of Example 1 of the copper wire mesh. figure 2 is a schematic diagram of Example 2 of the copper wire mesh. The copper wire mesh is braided by multiple longitudinal copper wires and multiple horizontal copper wires. Generally, there are 4 to 10 horizontal copper wires, and 10 to 50 vertical copper wires, and the specific number can be selected according to the needs. figure 1 The copper wire mesh in has 4 horizontal copper wires; figure 2 The copper wire mesh in has 6 horizontal copper wires.

[0031] The cross-section of the copper wire used to weave the copper wire mesh is round, square or flat, which can effectively reduce the shading of sunlight and reduce the loss of resistance.

[0032] image 3 It is a schematic diagram of the front of a cell without a busbar. Such as image 3 As shown, the busbar-free cell has multiple horizontal sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com