Steel plate coating device for insulating plate production line

A coating device and production line technology, which is applied in the field of steel plate coating devices and can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

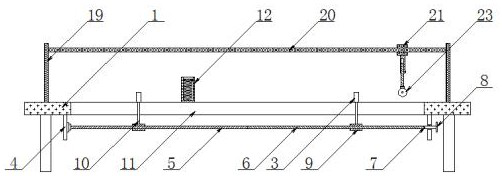

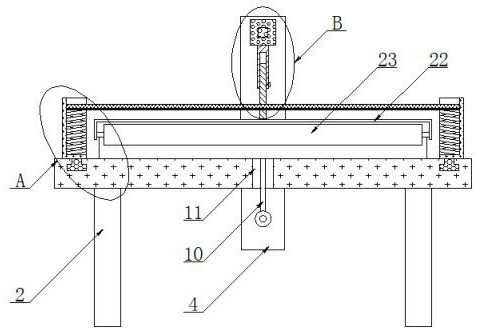

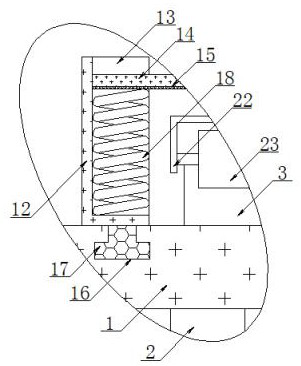

[0031] Such as Figure 1 to Figure 6 As shown, a steel plate coating device for an insulating board production line includes a workbench 1, and support legs 2 are fixed at the bottom of the workbench 1 near its four corners;

[0032] The worktable 1 is provided with a moving mechanism, and the top of the moving mechanism is provided with two splints 3, and the moving mechanism drives the two splints 3 to move relative to each other or to the back by rotating. The mounting plate 4 of the mounting plate 4 on the left side is provided with a screw rod one 5 rotating on the right side of the left mounting plate 4, and the free end of the screw rod one 5 is fixedly connected with a screw rod two 6 opposite to the thread of the screw rod one 5, and the free end of the screw rod two 6 is fixed with a rotating Rod 7, and the free end of rotating rod 7 rotates and stretches out right side mounting plate 4 and is fixed with rotating plate 8, and screw rod one 5 and screw rod two 6 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com