Device and method for preparing film-coated self-healing material

A film-coated device and composite material technology, which is applied in the field of devices for preparing film-coated self-healing materials, can solve the problems of complex operation methods, expensive, limited self-healing materials, etc., and achieve the effect of increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The device for preparing a film-coated self-healing material provided by the invention includes a detachable adsorption device and a film-coating device.

[0047] In the present invention, the suction device includes a vacuum component and a suction component.

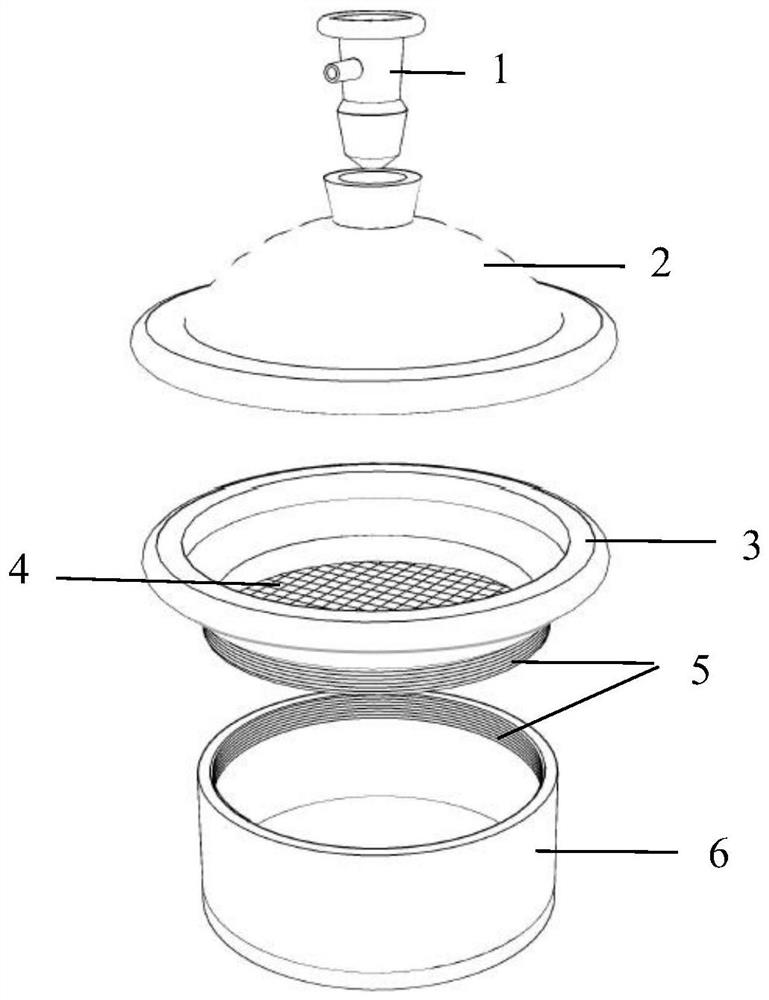

[0048] Such as figure 1 As shown, in the present invention, the adsorption assembly includes a vacuum suction head 1 , a top cover 2 , a hollow connecting device 3 and a circular groove 6 arranged in sequence from top to bottom.

[0049] In the present invention, the adsorption assembly includes a vacuum head 1 . In the present invention, there is no special limitation on the type and source of the vacuum pumping head, which can be adjusted according to usage requirements.

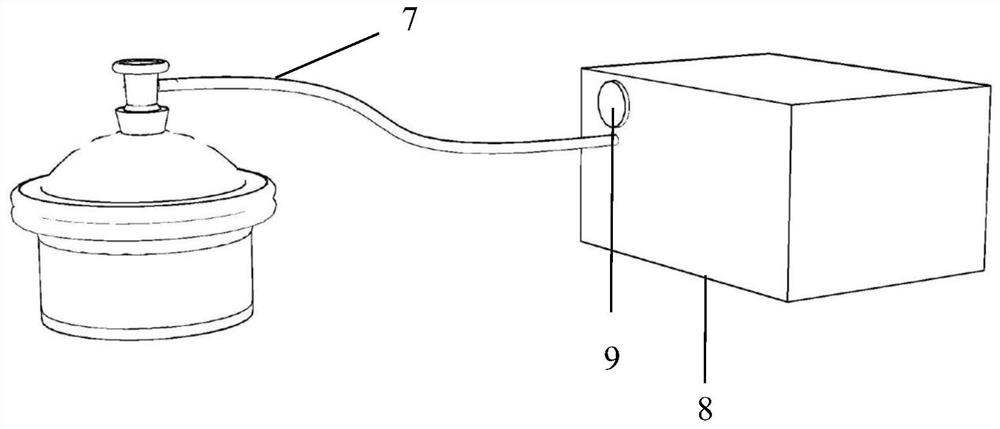

[0050] In the present invention, the upper end of the vacuum suction head is connected to the vacuum assembly through a hose, and the air in the adsorption assembly can be drawn out along the hose during vacuuming.

[0051] In the present i...

Embodiment 1

[0095] A device for preparing a film-coated self-healing material, including a detachable adsorption device and a film-coating device; the adsorption device includes a vacuum component and an adsorption component;

[0096] The device for preparing the film-coated self-healing material provided by the present invention includes two use states during use, that is, preparing the self-healing material and covering the film.

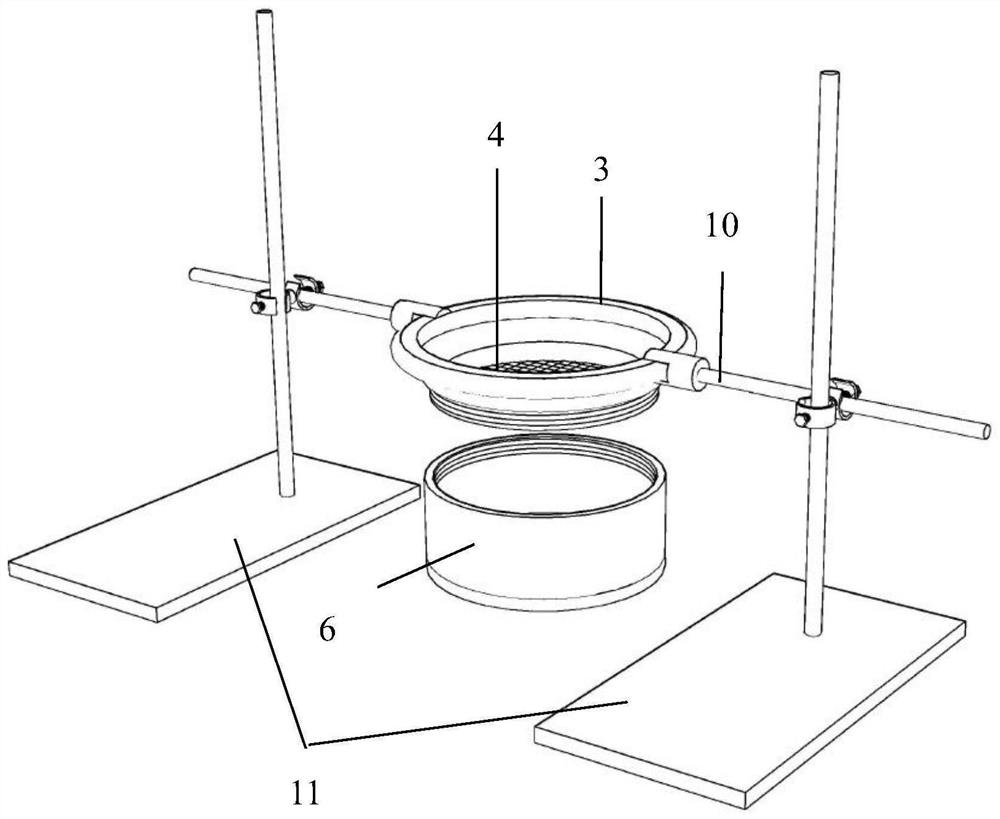

[0097] In the preparation of self-healing materials, such as figure 1 As shown, the adsorption assembly includes a vacuum suction head 1, a top cover 2, a hollow connection device 3, a gauze 4, a rotating thread 5 and a circular groove 6 arranged sequentially from top to bottom; the vacuum suction head 1 The upper end of the upper end is connected with the vacuum assembly through the hose 7; the bottom of the hollow connecting device 3 is provided with a mesh 4; the hollow connecting device is connected with the circular groove through a rotating thread 5;

...

Embodiment 2

[0101] The device of Example 1 was used to prepare a self-healing material. The specific process is as follows:

[0102] (1) Weigh the ceramsite in a blast drying oven and dry it at 60°C for 24h.

[0103] (2) Pour 200 g of the dried ceramsite obtained in step (1) into the circular groove 6, add 60 mL of a sodium carbonate solution with a mass concentration of 10%, and connect the circular groove 6 and the hollow connection device 3 by rotating threads , so that the mesh is located below the liquid surface of the self-healing material solution.

[0104] (3) Apply vaseline on the contact surface of the vacuum pumping head 1, the top cover with a convex groove 2 and the hollow connection device 3 for sealing, connect the pumping hose 7, turn on the vacuum pump 8 and start pumping until the value of the barometer 9 reaches -0.1MPa. Vacuum adsorption for 40 minutes; after the adsorption is completed, filter the ceramsite that has absorbed the sodium carbonate solution through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com