Packaging box film coating and sealing device suitable for different sizes

A sealing device and packaging box technology, which is applied in packaging, transportation and packaging, and box production operations, etc., can solve the problems of the box body being sucked and unable to be coated, and achieve the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

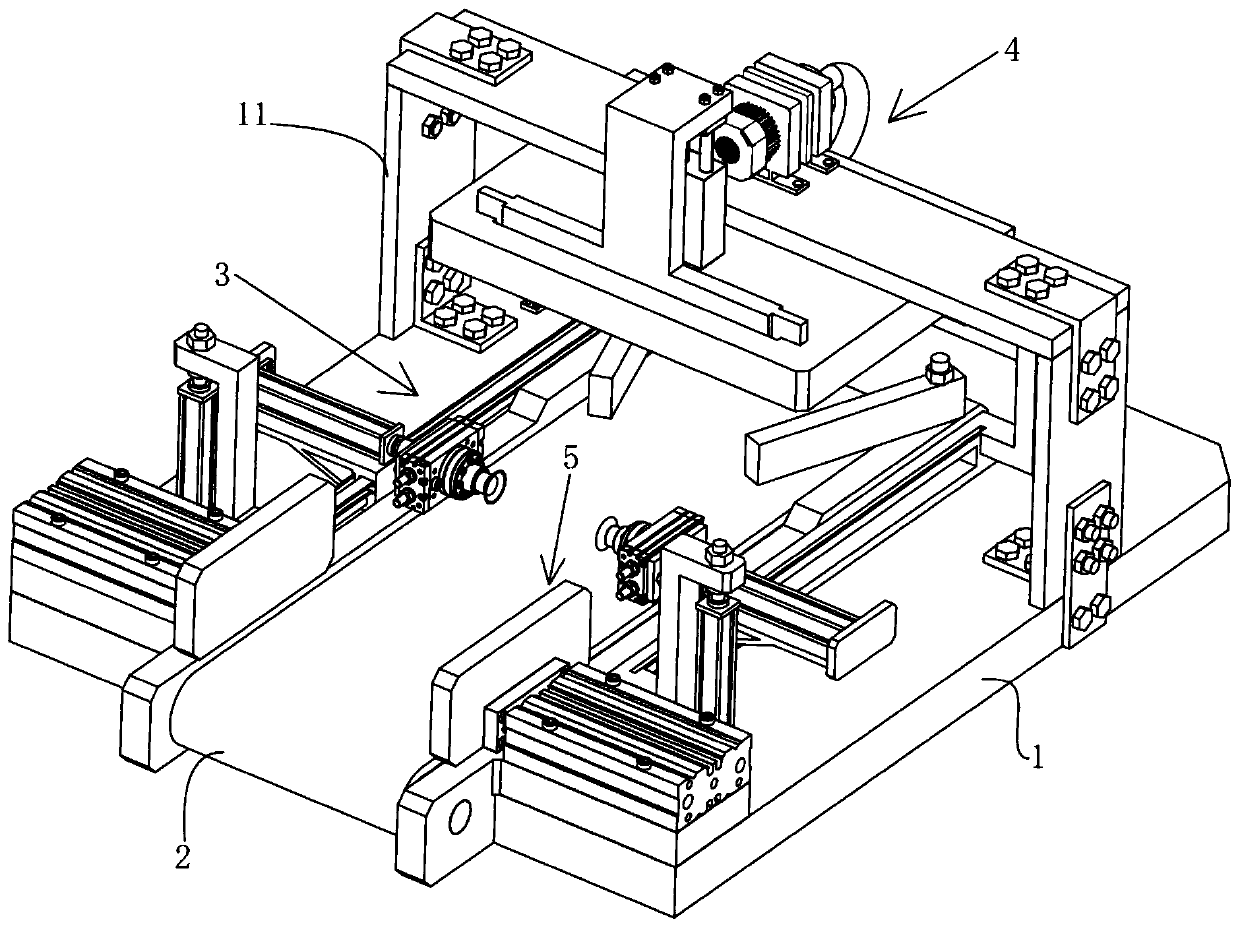

[0027] see Figure 1 to Figure 6 , the present invention provides a technical solution:

[0028] A film-coated sealing device suitable for different sizes of packaging boxes, including a bottom plate 1, a conveyor belt 2, a clamping mechanism 3, a film-coating mechanism 4, and an edge-sealing mechanism 5, wherein:

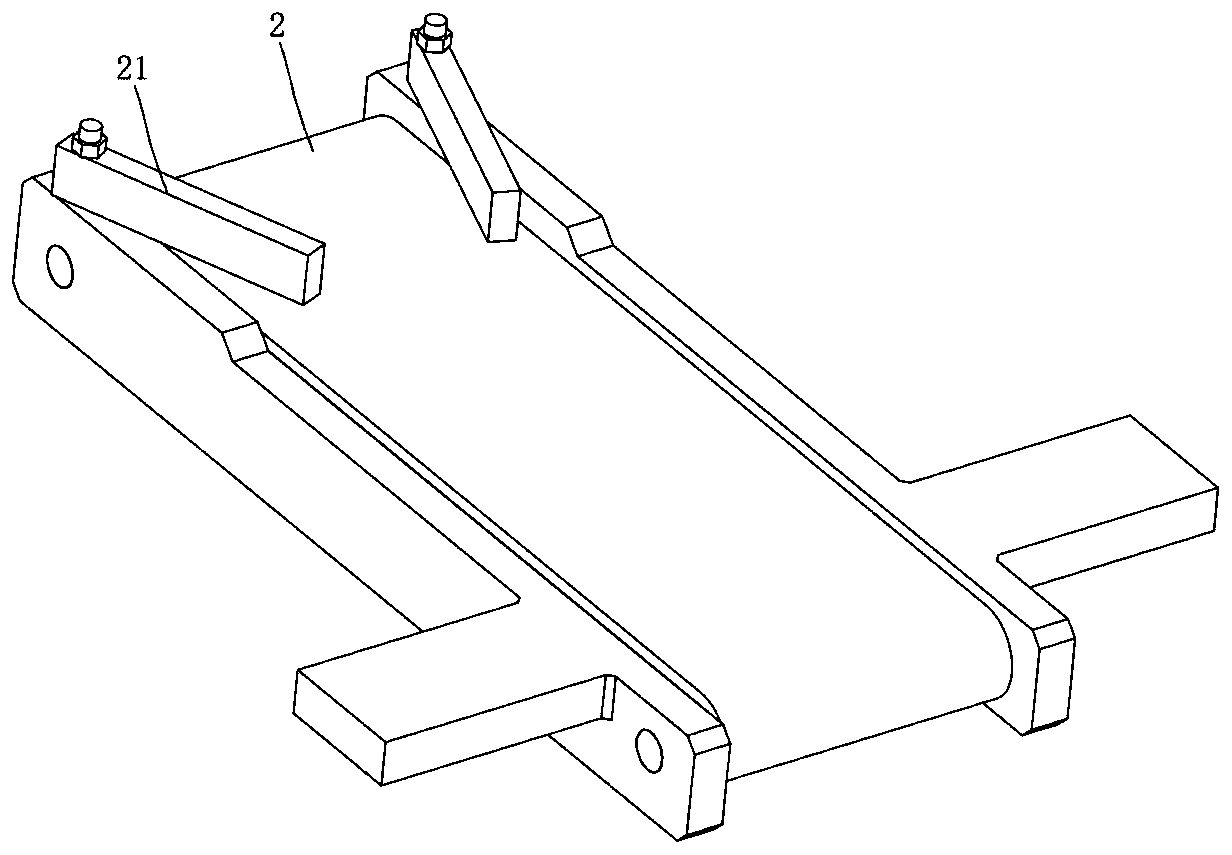

[0029] Conveyor belt 2 is installed in base plate 1, and the both sides of conveyer belt 2 is provided with baffle plate 21, and wherein baffle plate 21 is installed on the side plate of conveyer belt 2 by pin, and pin shaft extends to the upper side of baffle plate 21 and Nuts are provided to fix the baffles 21, and the baffles 21 on both sides can bring the goods to the middle of the conveyor belt 2 for transportation;

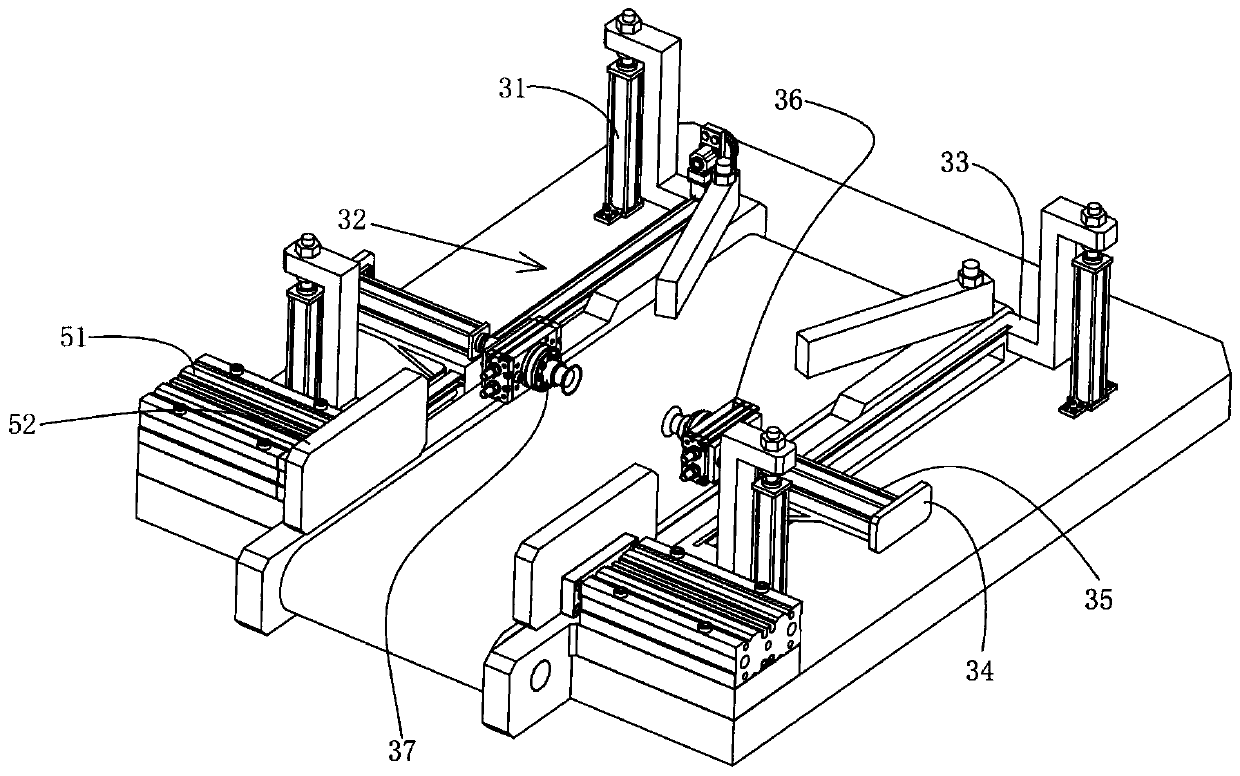

[0030] The clamping mechanism 3 includes a hydraulic cylinder 31, a linear drive mechanism 32, a guide rail 33, a slider 34, a single-axis cylinder 35, a rotary cylinder 36 and a push rod 37, and one end of the four hydraulic cylinders 31 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com