Buffering type storing box for manufacturing of sensor

A storage box and sensor technology, applied in the field of buffer storage boxes for sensor manufacturing, can solve the problems of cumbersome operation steps, inability to reduce the degree of wear of sensors and storage boxes, and high cost, so as to protect sensors, use convenient and reasonable methods, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

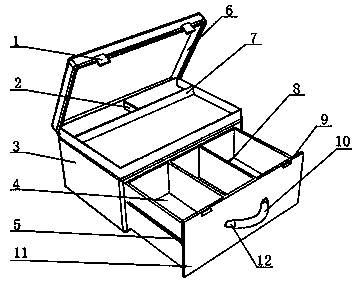

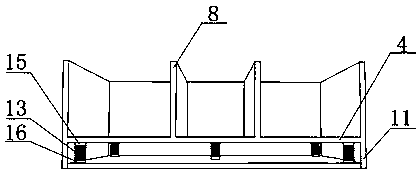

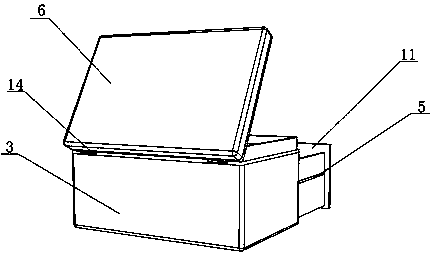

[0018] see Figure 1~4 , in an embodiment of the present invention, a buffer storage for sensor manufacturing, including a box body 3, two hinges 14 with the same structure and size are arranged symmetrically on the top of the rear side of the box body 3, and the box body 3 passes through the hinges 14 A box cover 6 is fixedly connected, and the top of the rear side of the box cover 6 is symmetrically provided with two locks 1 with the same structure and size. The middle parts of the two symmetrical sides of the box body 3 are provided with slide rails and there are long strips sliding along them. The buckle 5 and the side of the strip buckle 5 are fixedly connected with a storage drawer 11, and the rear side of the storage drawer 11 is fixedly connected with a handle 12, and the rear side top of the storage drawer 11 is symmetrically provided with two structures on the rear side surface of the storage drawer 11. And the buckle 9 that size is all the same.

[0019] exist fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap