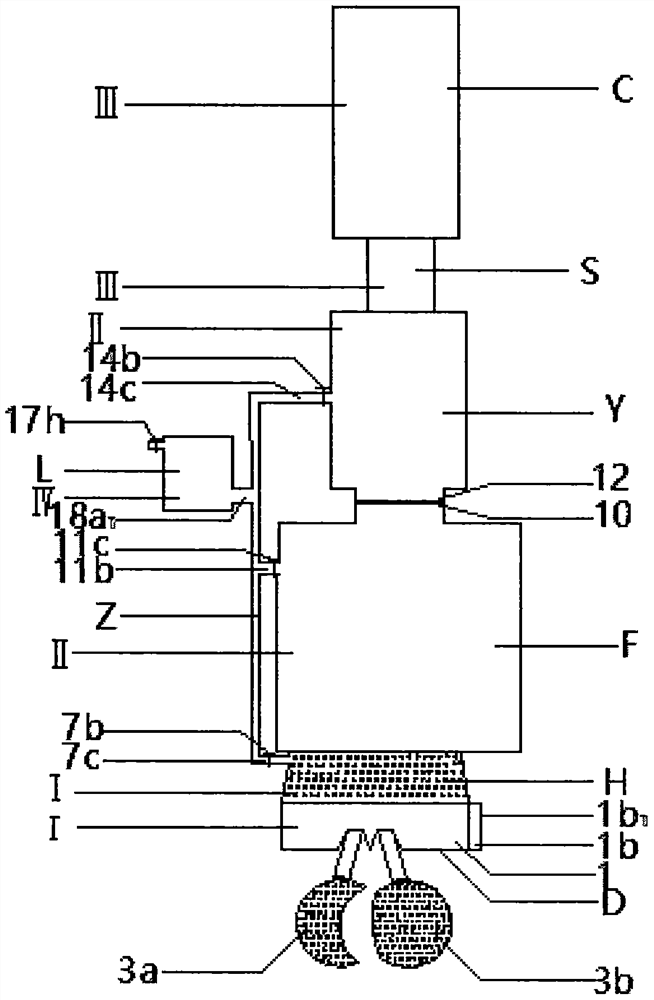

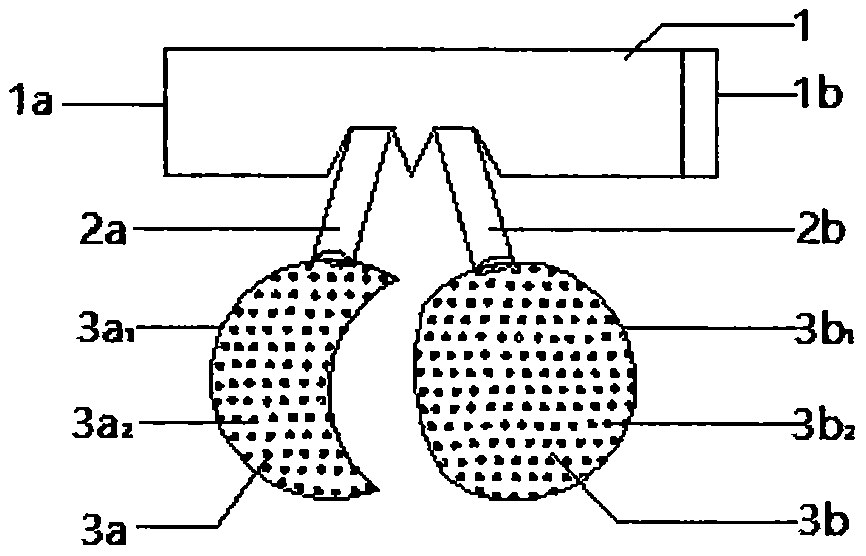

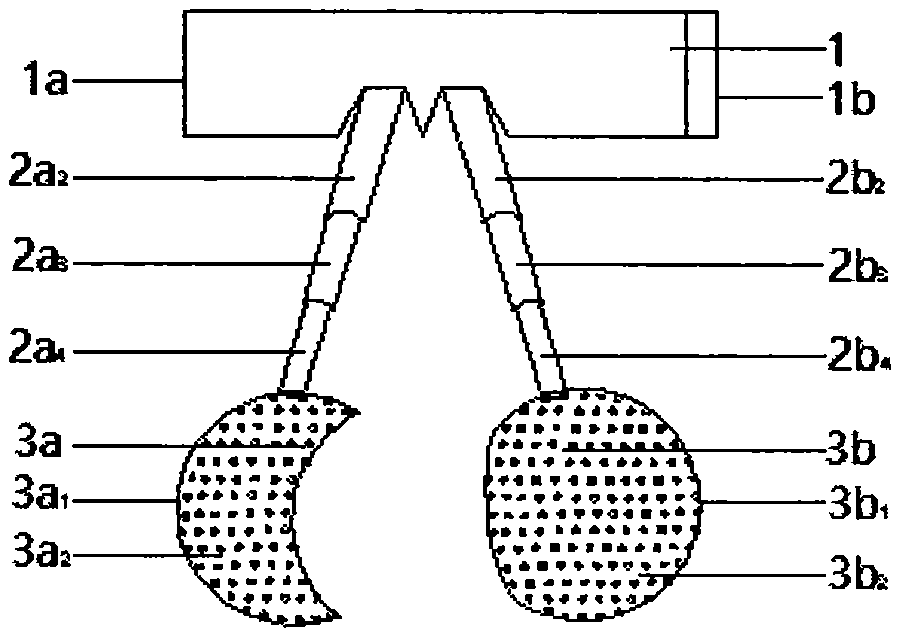

[0006] An integrated method for collecting and processing floating objects on water, which is characterized in that it overcomes the problem of the singleness of the existing floating cleaning methods, and can complete a series of processes such as salvaging, crushing, compressing and packing, and storing floating objects on the water by using the method, and realizes cleaning. An integrated treatment of floating objects; an integrated method for collecting and processing floating objects on water combines four stages and one process, including salvage of floating objects and slideway transportation, crushing, compression packaging, transportation and storage, and water treatment. In this stage, the floating objects on the water are salvaged and the floating objects are transported through the slideway; in the salvage equipment, the fishing rod A and the fishing rod B change from the shrinking state to the stretching state under the action of the driving device, so that they The connected net gear A and net gear B first fall below the water surface for salvage operation, and then the net gear A and net gear B change from being separated to gathering to form a net pocket. If some floating substances fall, they can be salvaged multiple times and salvaged immediately Rod A and fishing rod B change from stretched state to contracted state under the action of driving device A and driving device B, and at the same time, under the action of driving device A and driving device B, the fishing equipment is lifted upwards. , The nets B slide down onto the slideway, the sewage in the floating objects flows into the water collection tank without a cover through the small holes of the slideway plate with holes during the sliding of the floating objects, reaches the water outlet i, and then connects to the main pipeline through the branch pipe i And the sewage is poured into the water treatment part through the branch pipe iv, and the floating matter slides down to the bottom of the slideway, and is connected with the crushing equipment through the slideway to reach the feeding port i of the crushing equipment; followed by the crushing stage, the floating matter enters the crushing stage. The feed port i of the equipment enters into the central equipment along the feed port i, where the side knife and the rotary knife are cut and crushed, and the floating matter is ground for many times in the gap between the rotary knife and the side knife. While crushing and grinding materials, a large amount of air is sucked in from the feed port, and these gases play a role in cooling the machine. The pillars A and B provide support and stability for the rotary knife during operation, and finally the crushed materials come out of the The discharge port i is discharged, and the leached sewage is connected to the main pipeline through the outlet ii at the bottom and then connected to the main pipeline through the branch pipe ii, and the sewage is directed to the water treatment part through the branch pipe iv, and then the pulverized floating matter enters through the discharge port i into the compression packaging equipment; again for the compression packaging stage, the pulverized material enters the compression zone from the feed port of the compression packaging equipment, before the lifting drive device is started, the connecting chain is in an elongated state, vertically connected to the jack, and the push plate is in contraction shape, the push rod connected to the push plate is also contracted, the baffle is in an extended state, the length just reaches the lower end of the lifter, and the discharge port ii is in a closed state. When the crushed material entering reaches a certain volume, the lifting After the driving device is started, the connecting chain is scaled, the jack is pressed down, the push plate is quickly extended to the lower end of the jack, and then the push rod starts to extend forward, pushing the push plate forward to compress, and when the compression is completed, the baffle plate Back to the initial height, the hoisting drive device scales the connecting chain to lift the jack up, the spring drives the pressure plate up until the baffle is flush with the packing area, and the push plate continues to push forward, so that the compacted crushed materials enter the material Compressed bag until full, then sealed by sealing equipment Sealing, after sealing, the packaged material is pushed out from the discharge port ii, and the packaged material is transported to the conveyor belt device by the push plate, and the sewage generated in this process is connected to the main pipe through the water outlet iii and then through the branch pipe iii and enter the water treatment part through the branch pipe iv; the last stage is the conveying and storage stage, when the packaged material reaches the conveyor belt device for transmission, the roller A with the driving device and the roller B with the driving device drive the belt to push the material forward, The roller bracket A, the roller bracket B and the horizontal bracket play a role in stabilizing the operation of the equipment; the final packaged materials arrive at the storage platform after being conveyed, and are temporarily stored by the storage platform, waiting for the staff to process them; the water treatment process and salvage and The slideway conveying stage, crushing stage, and compression packing stage are carried out simultaneously, and the sewage flowing out from the slideway, crushing equipment, and compression packing equipment is connected to the main pipeline through branch pipe i, branch pipe ii, and branch pipe iii, and then flows into the water treatment part through branch pipe iv , the sewage enters from the upper water inlet, first passes through the water inlet area, then passes through the first-level grid to remove large impurities in the water, and then enters the packing area, where honeycomb packing and activated carbon made of polyvinyl chloride plastic are laid. The honeycomb filler is located in the upper part, and the activated carbon is located in the lower part. The secondary grid is used as a support to further remove fine particles in the water. There are microorganisms hanging on the honeycomb filler to perform biochemical reactions and physical adsorption of activated carbon, and then reach the first section of the water outlet. According to the corresponding discharge standard, open the valve iv on the water outlet iv in the water outlet section 1 to discharge the treated water. If the discharge standard is not met, close the valve iv of the water outlet section 1 section and open the valve v of the water outlet section 2 to discharge the treated water. The water enters through the membrane inlet and is connected to the single membrane member through the pipeline for membrane treatment. This treatment not only improves the removal efficiency of pollutants, but also improves the quality of the effluent water. After the final treatment, the water that meets the standard passes through the membrane outlet and then opens the valve vi Discharge through outlet v

Login to View More

Login to View More  Login to View More

Login to View More