A technology for side construction and side lying construction and transportation of large jackets

A jacket and process technology, which is applied in the field of large-scale jacket side construction and side lying construction and transportation technology, can solve the problem of small contact area between the jacket and the deck of the transport ship, increase the contact area between the jacket and the transport ship, and increase the transportation capacity. Problems such as ship roll and lateral moment, to ensure the safety and stability of transportation, facilitate the arrangement of lashing, and adjust the distance in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

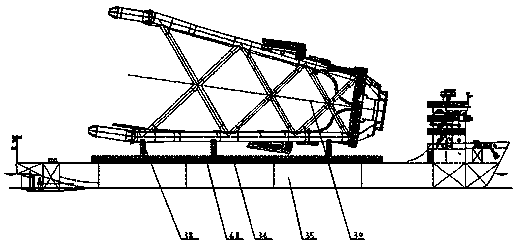

[0071] Such as figure 1 As shown, a side-building and side-lying construction and transportation process for large-scale jackets, the specific steps are as follows:

[0072] A. Production of transition section:

[0073] a. Prefabricate 4 main leg pipes 16 of the transition section: prefabricate the cylindrical part and the groove part of the main leg pipe 16 of the transition section, and weld the cylindrical part and the groove part to ensure the connection between the cylindrical part and the groove part The longitudinal seams are staggered by 180°;

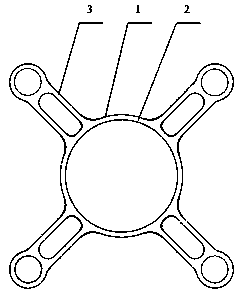

[0074] b. Prefabricate a lower panel 1: as figure 2 As shown, a circular body 2 and four extended plate bodies 3 are cut, the circular body 2 and the extended pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com