Oil pan with variable oil mass

A technology of oil pan and oil quantity, which is applied in the direction of oil pan, engine components, machines/engines, etc. It can solve the problem of oil connection and separation between inner and outer oil pans, slow oil temperature rise in the inner oil pan, and zero There are many parts, etc., to achieve the effect of simple structure, fast oil discharge speed and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following specific examples illustrate the present invention in further detail.

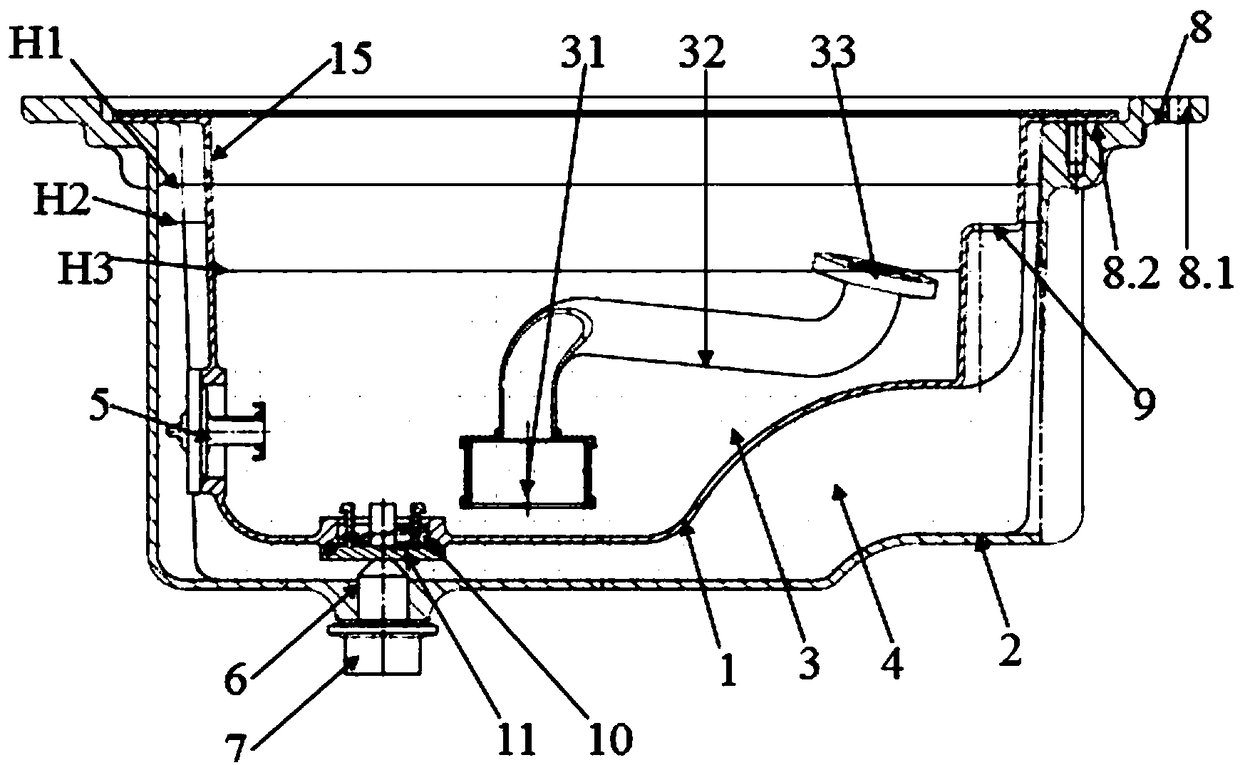

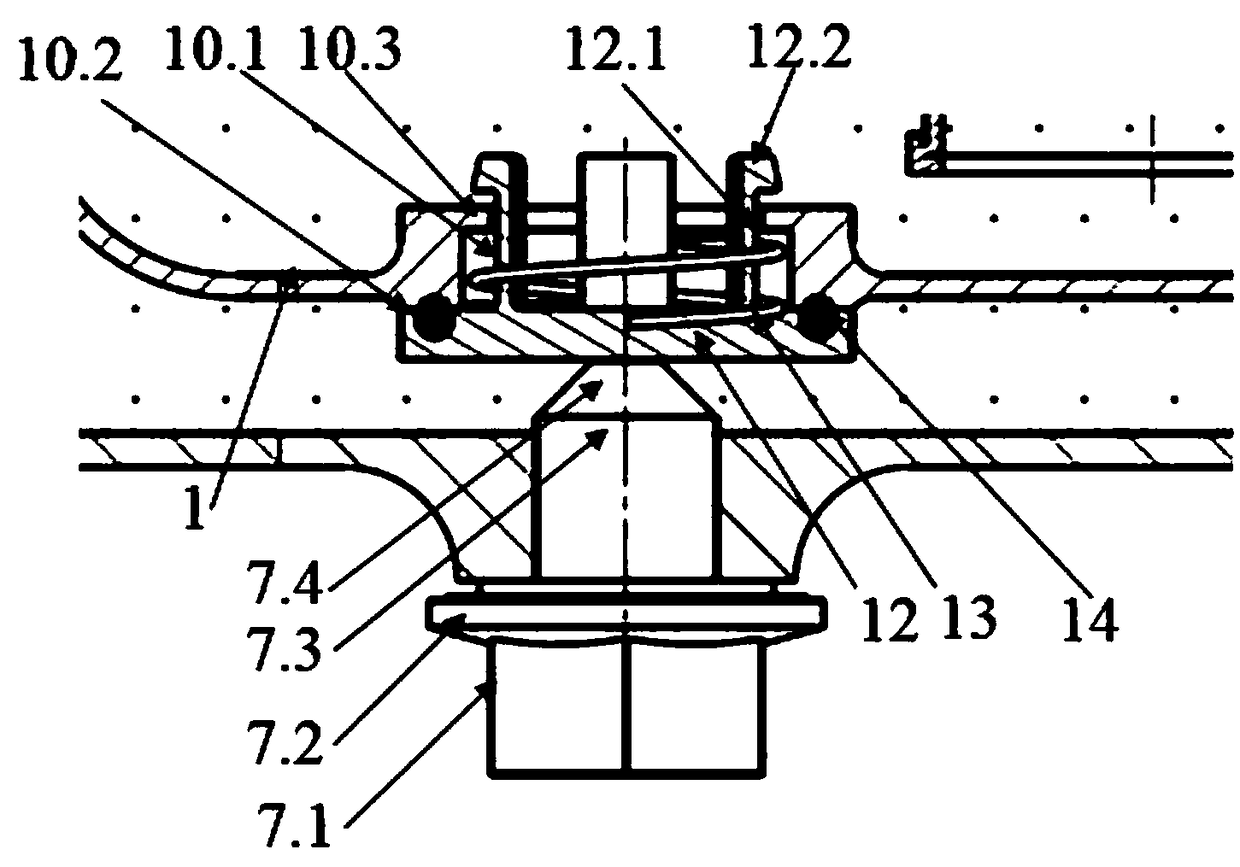

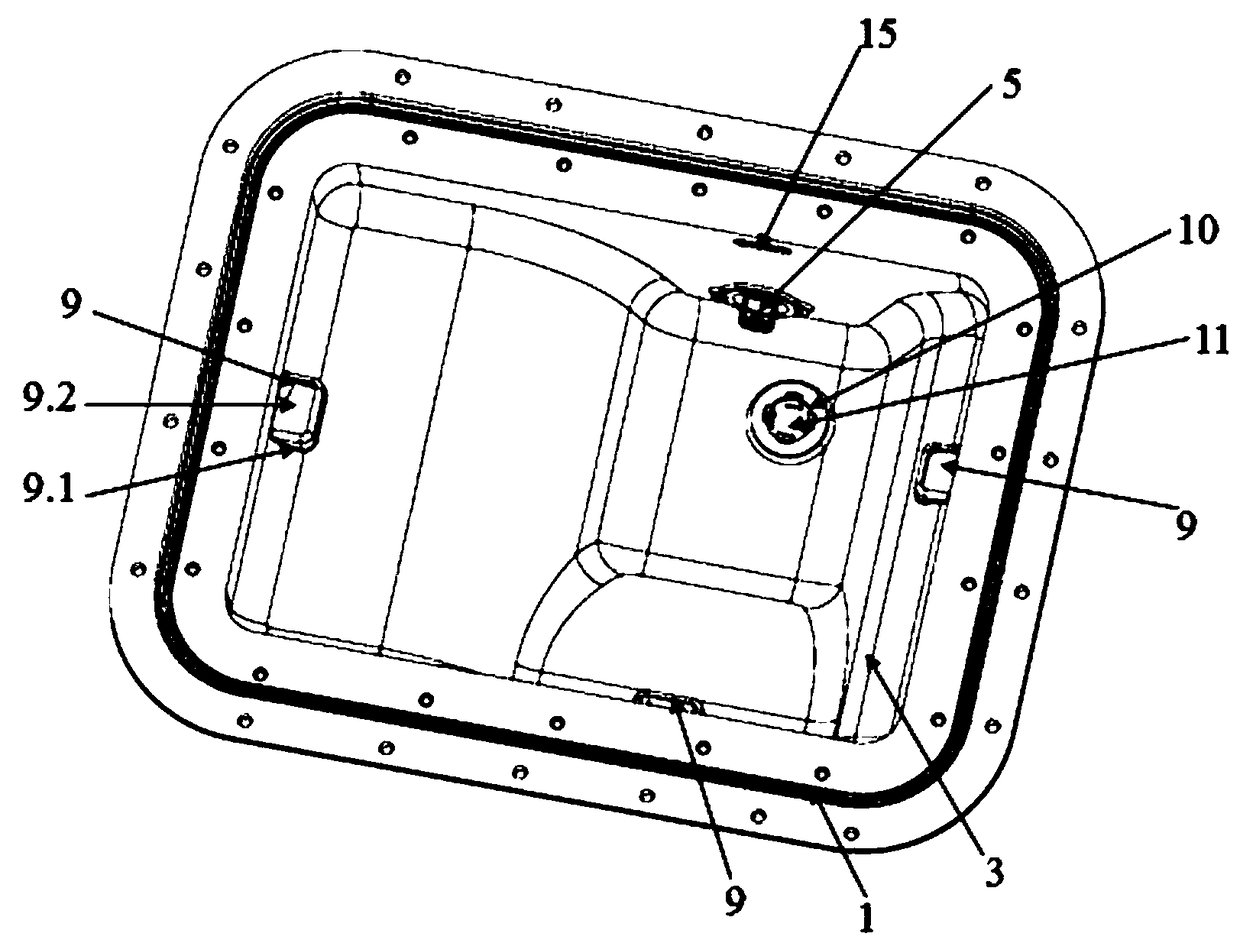

[0035] Such as figure 1 As shown, a variable oil volume oil pan provided by the present invention includes an inner oil pan 1 and an outer oil pan 2, the inner oil pan 1 has a first chamber 3, the inner oil pan 1 and the outer oil pan The second chamber 4 is formed between the two oil pans, the first chamber 3 is provided with a thermostat valve 5 communicating with the second chamber 4, the bottom of the outer oil pan 2 is provided with an external oil discharge port 6, and the external oil discharge The port 6 is provided with an external oil drain plug 7, and the opening of the outer oil pan 2 is provided with a mounting part 8 which is in sealing connection with the opening of the inner oil pan 1, and the second chamber 4 is the outer oil pan 2 and the inner oil tank. The circumferential gap and the bottom gap of the bottom shell 1 are connected, and the side wall of the first chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com