Ejection device for moving die on wax injector

A technology of ejection device and wax press machine, which is applied in the direction of casting and molding equipment, can solve the problems of affecting work efficiency, time-consuming and laborious cleaning of wax on the workbench, and wax running, so as to achieve a smooth moving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

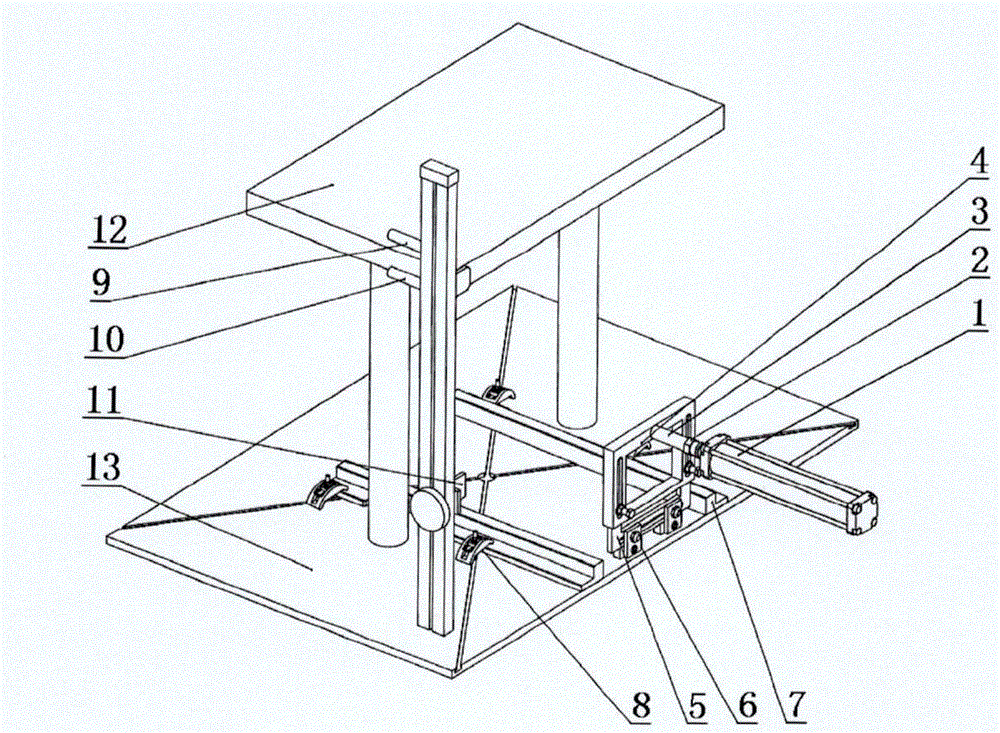

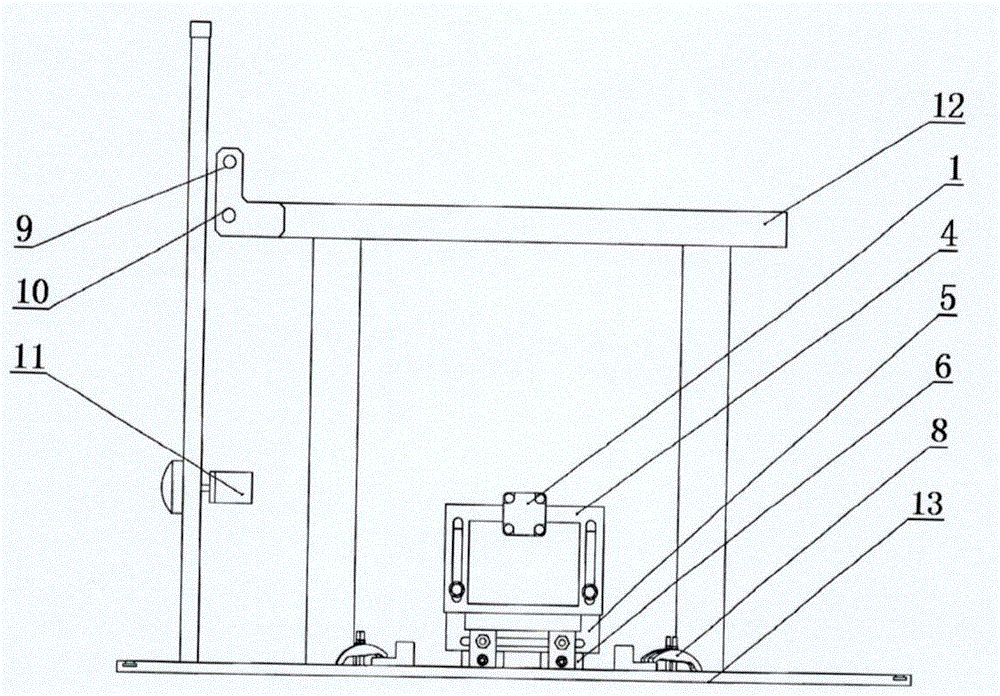

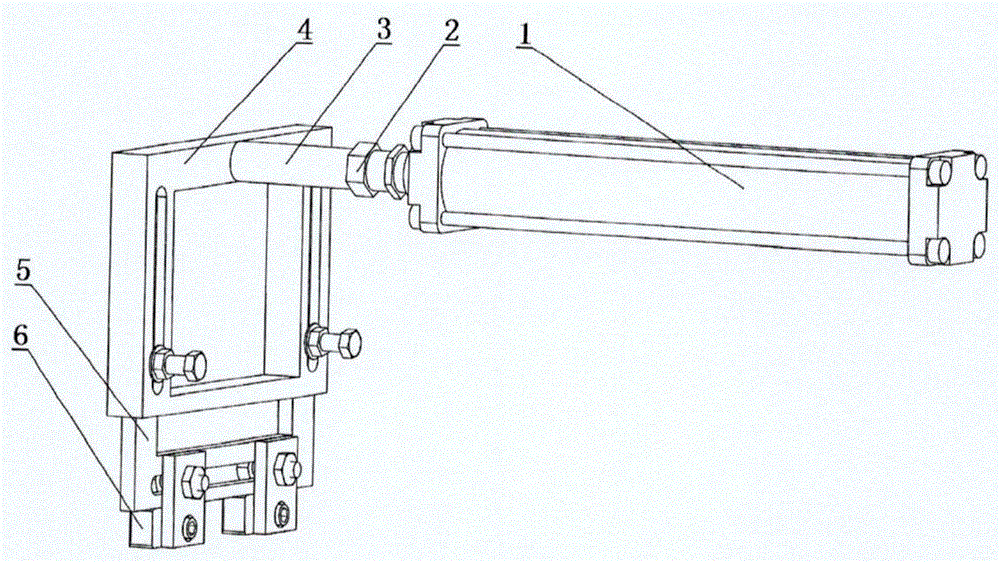

[0025] An ejector device for moving molds on a wax press, such as figure 1 , figure 2 As shown, the manual core pulling device includes a hydraulic cylinder 1, a connecting rod nut 2, a connecting rod 3, a fixed frame 4, a movable frame 5, a top die movable block 6, a limit guide rail 7, a pressure plate assembly 8, and a limiter I9 , limiter II10, limit baffle 11, moving template 12 of wax press machine, fixed template 13 of wax press machine, wherein, the ejector mechanism includes hydraulic cylinder 1, connecting rod nut 2, connecting rod 3, fixed frame 4, can The movable frame 5 and the movable block 6 of the top mold, the fixed frame 4 and the connecting rod 3 are connected by welding, the other side of the connecting rod is connected with the hydraulic cylinder 1 through the nut 2, and the movable frame 5 and the fixed frame 4 are matched. The height of the frame 5 can be adjusted by the tightening bolts to adapt to molds of different heights. The entire ejector mechan...

Embodiment 2

[0027] Such as Figure 4 As shown, the limit guide rail 7 is detachable, and when in use, it is fixed on the fixed template 13 of the wax injection machine by using the pressure plate assembly 8, and the width of the limit guide rail 7 can be adjusted according to the size of the mold. 7 width.

Embodiment 3

[0029] When the ejector device for moving the mold on the wax press machine according to Embodiment 1 or Example 2 of the present invention is used, the hydraulic cylinder is placed on the wax injection nozzle of the wax press machine, and the wax injection nozzle of the wax press machine and the fixed frame 4, can move The frame composed of frame 5 is coaxial, and the signal fed back by the limiter is well combined with the main body of the wax presser. When the stopper II on the moving template passes through the limit baffle during the mold closing process of the wax presser, the template decelerates. When the stopper II is reached, the wax pattern is pressed. After the wax pattern is pressed, the mold is opened. Before the stopper II, the template is slowly opened. When the stopper II is passed, the template is accelerated to open the mold. At this time, the hydraulic cylinder of the ejection mechanism It will also receive the start signal, and start to move and eject the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com