Plastic product vacuum coating equipment with multiple applicable specifications

A technology of vacuum coating and plastic products, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of time-consuming and laborious, mixed coating of workpieces, low work efficiency, etc. , moving effect smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

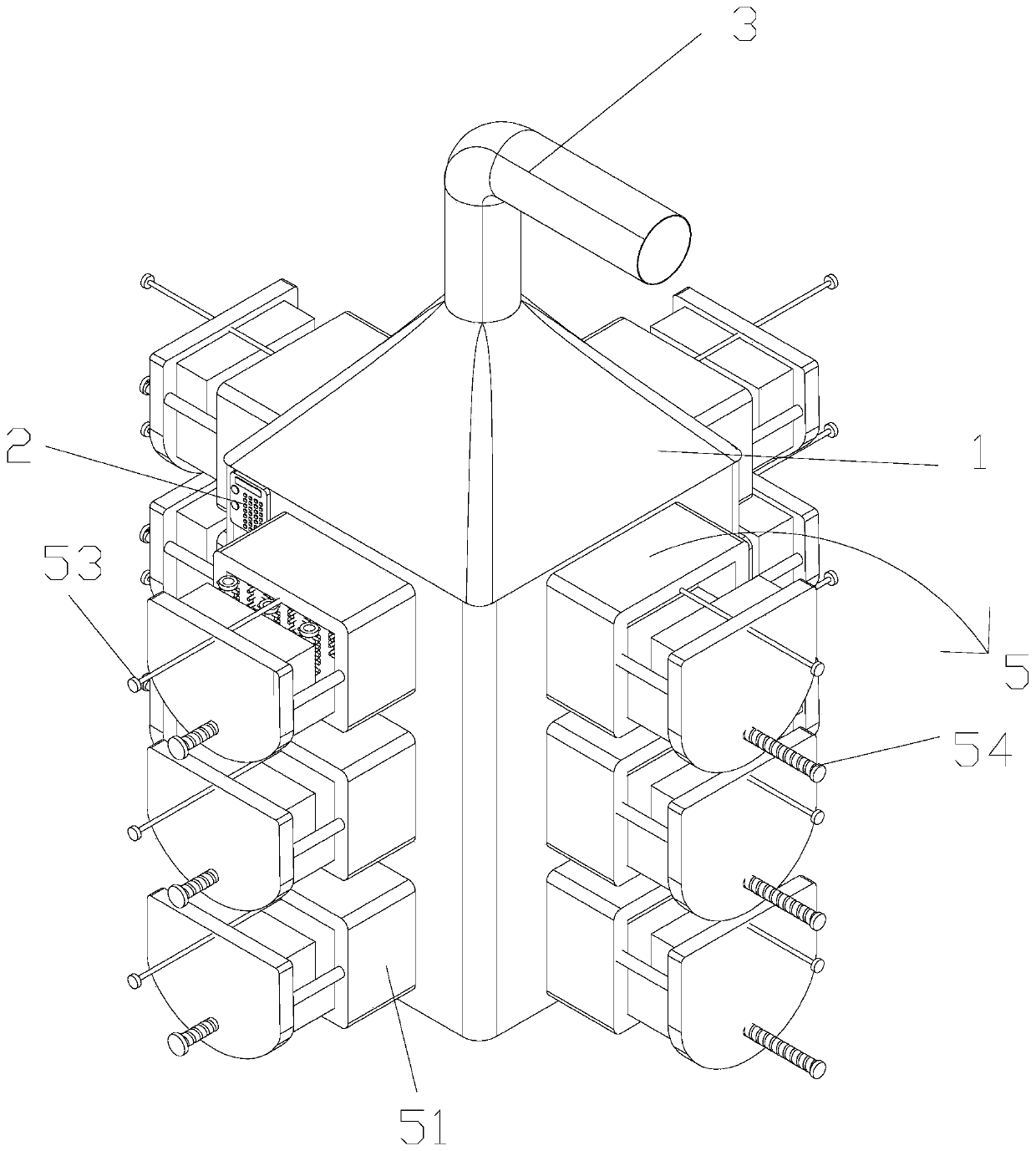

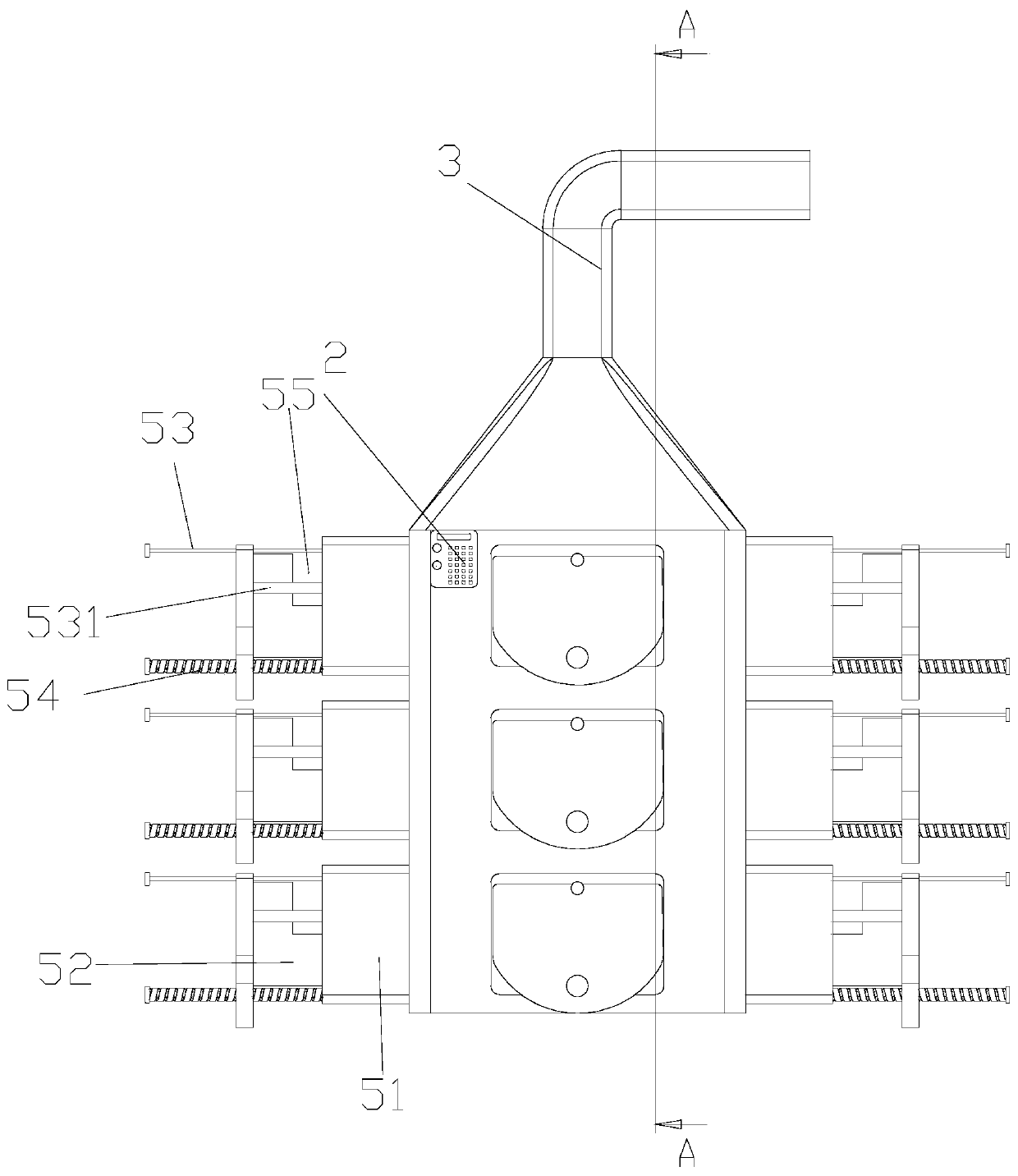

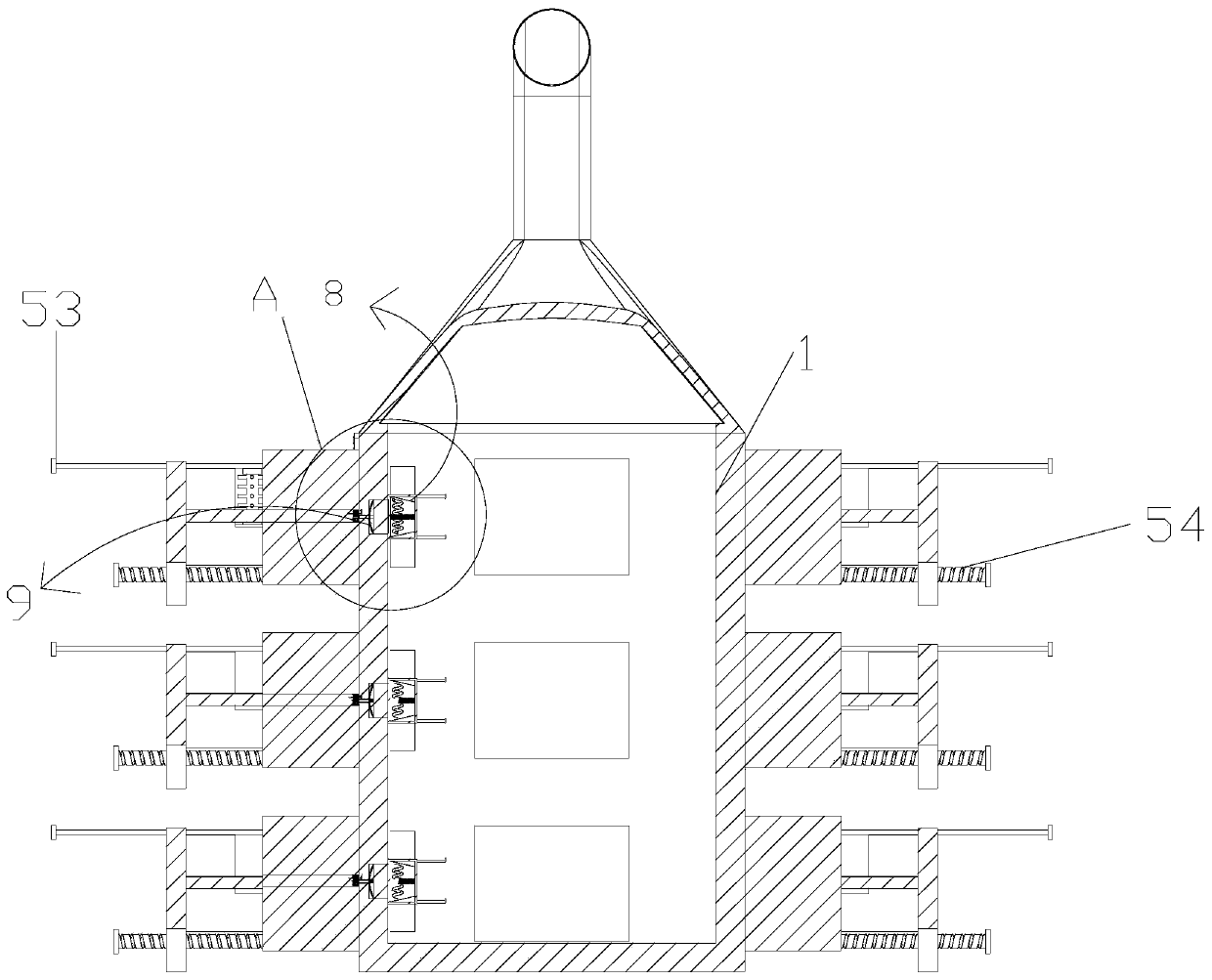

[0038] Such as Figure 1-16 As shown, a vacuum coating equipment for plastic products with multiple applicable specifications includes a vacuum coating chamber 1, a controller 2, an exhaust pipe 3, a locking groove 4 and a coating device 5; the controller 2 is fixed on the vacuum coating chamber 1 connected; the exhaust pipe 3 is fixedly connected at the top of the vacuum coating chamber 1; the number of the coating devices 5 is multiple, and the intervals are evenly distributed on the vacuum coating chamber 1; the number of the locking grooves 4 is multiple, respectively On the left and right sides of the coating device 1.

[0039] The coating device 5 includes a through hole 50, a convex portion 51, a connecting seat 52, a guide shaft 53, a screw rod 54, a groove 55, a pillar 56, an extrusion bump 57, an extrusion head 58, a driving groove 59, and a clamp mechanism 6 and the driving mechanism 7; the number of said through holes 50 is multiple, and they are evenly spaced on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com