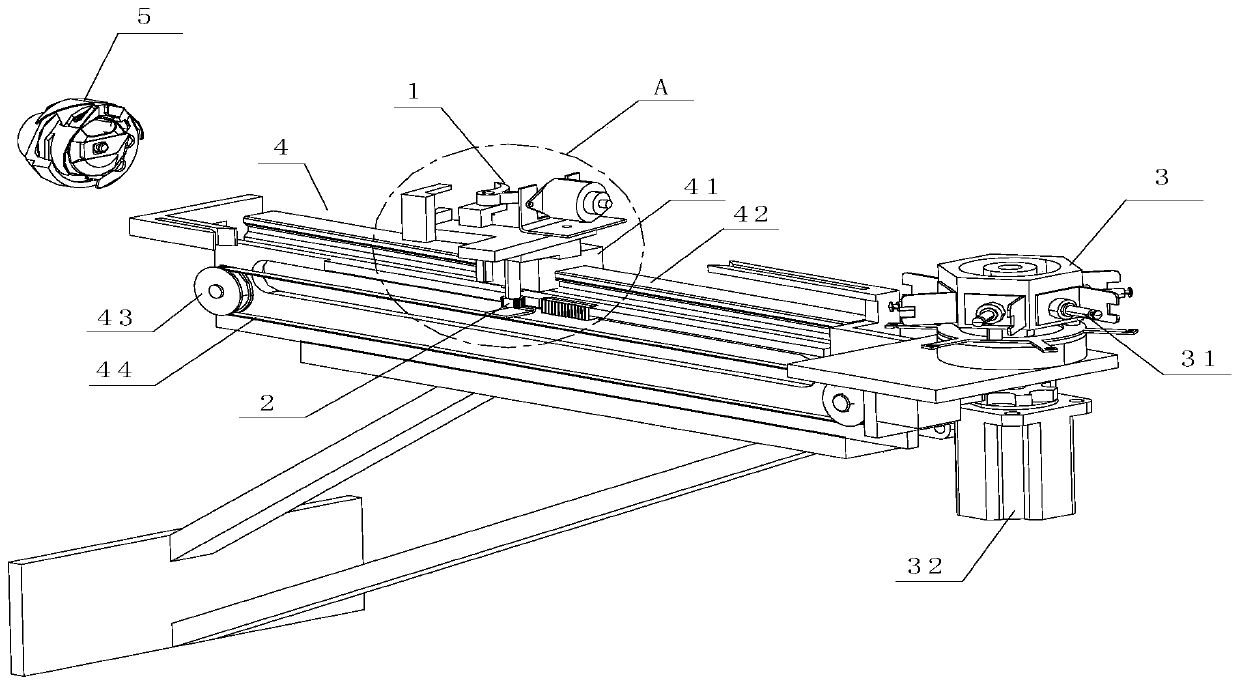

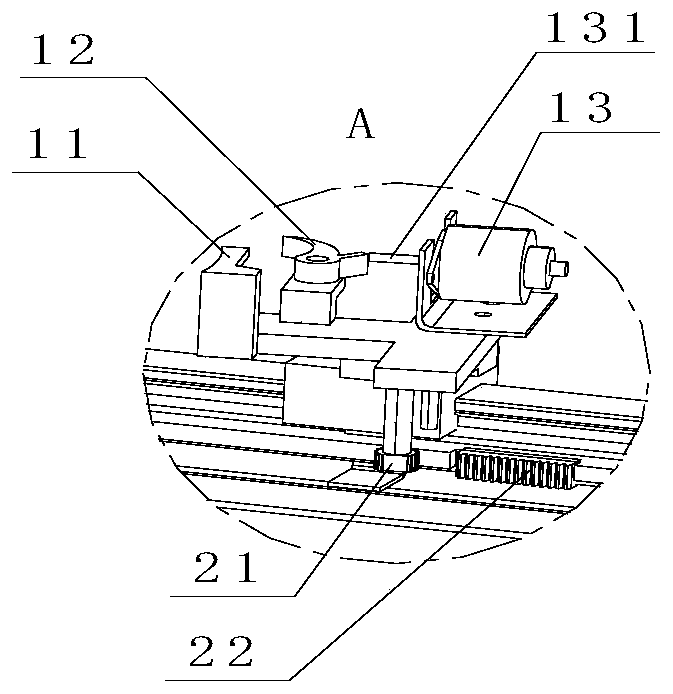

Automatic shuttle-changing device of sewing machine

A technology of a sewing machine and a rotary drive device, which is applied to the winding of the bobbin in the sewing machine, the components of the sewing machine, the sewing equipment, etc., can solve the problems of the inconvenient replacement of the bobbin, the unstable process of changing the shuttle, and the easy falling out of the lock cylinder. The effect of easy replacement, high reliability and smooth moving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

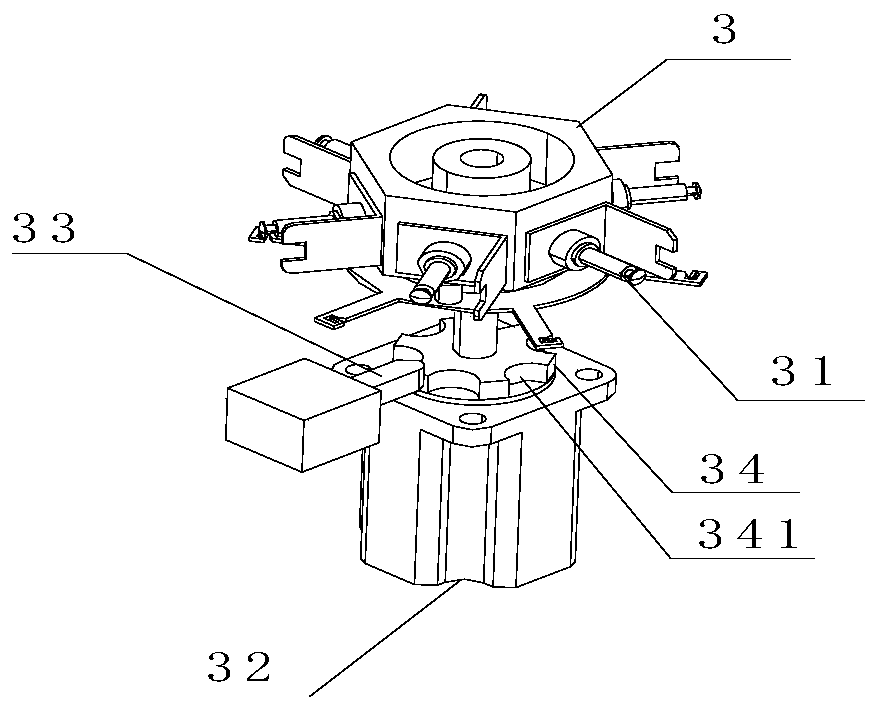

[0068] like Figure 4 and Figure 5 As shown, the automatic shuttle changing device is fixedly installed on the frame 7 through the bracket 71, the bobbin case in the rotary hook 5 and the bobbin case in the storage part 3 are located at the same height, and both are very close to the bottom of the platen 6 surface. In addition, the storage part 3 is also provided with a lifting mechanism 8, and the lifting mechanism 8 includes a lifting guide rail 45 arranged at the front end of the conveying mechanism 4, a lifting slide block 36 arranged on the storage part 3 and fixedly installed on the storage part 3 through a mounting seat 82. The linear drive device 81 below. Wherein, the lifting slide block 36 is installed under the polygonal column through the connecting plate 35 , and is slidably connected with the lifting guide rail 45 . The linear drive device 81 can use devices such as linear motors or cylinders, so that its output shaft is connected to the bottom of the storage...

Embodiment 2

[0070] like Figure 6 and Figure 7 As shown, in the second embodiment, the automatic shuttle changing device is fixedly installed on the frame 7 through the bracket 71, and the height of the bobbin case in the rotary hook 5 is greater than the height of the bobbin case in the storage part 3, that is, the bobbin case in the rotary hook 5 Closer to the lower surface of the platen 6, the storage part 3 is fixed below the conveying mechanism 4 through the bracket 72, so that there is a sufficient distance between the storage part 3 and the platen 6 for the operator to take out the storage part 3. On this basis, the conveying mechanism 4 is also provided with a lifting mechanism 8, and the lifting mechanism 8 drives the conveying mechanism 4 to carry out lifting motion. The rack 22 is fixed between the linear guide rail 42 and the synchronous belt 44 through the connecting rod 23 , and can move up and down simultaneously with the conveying mechanism 4 and remain in the moving str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com