Special device for thermal infrared imager test of laminate

A technology of infrared thermal imaging and special devices, which is applied in measuring devices, optical radiation measurement, radiation pyrometry, etc., to achieve the effects of avoiding cumbersome operation processes, improving detection efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

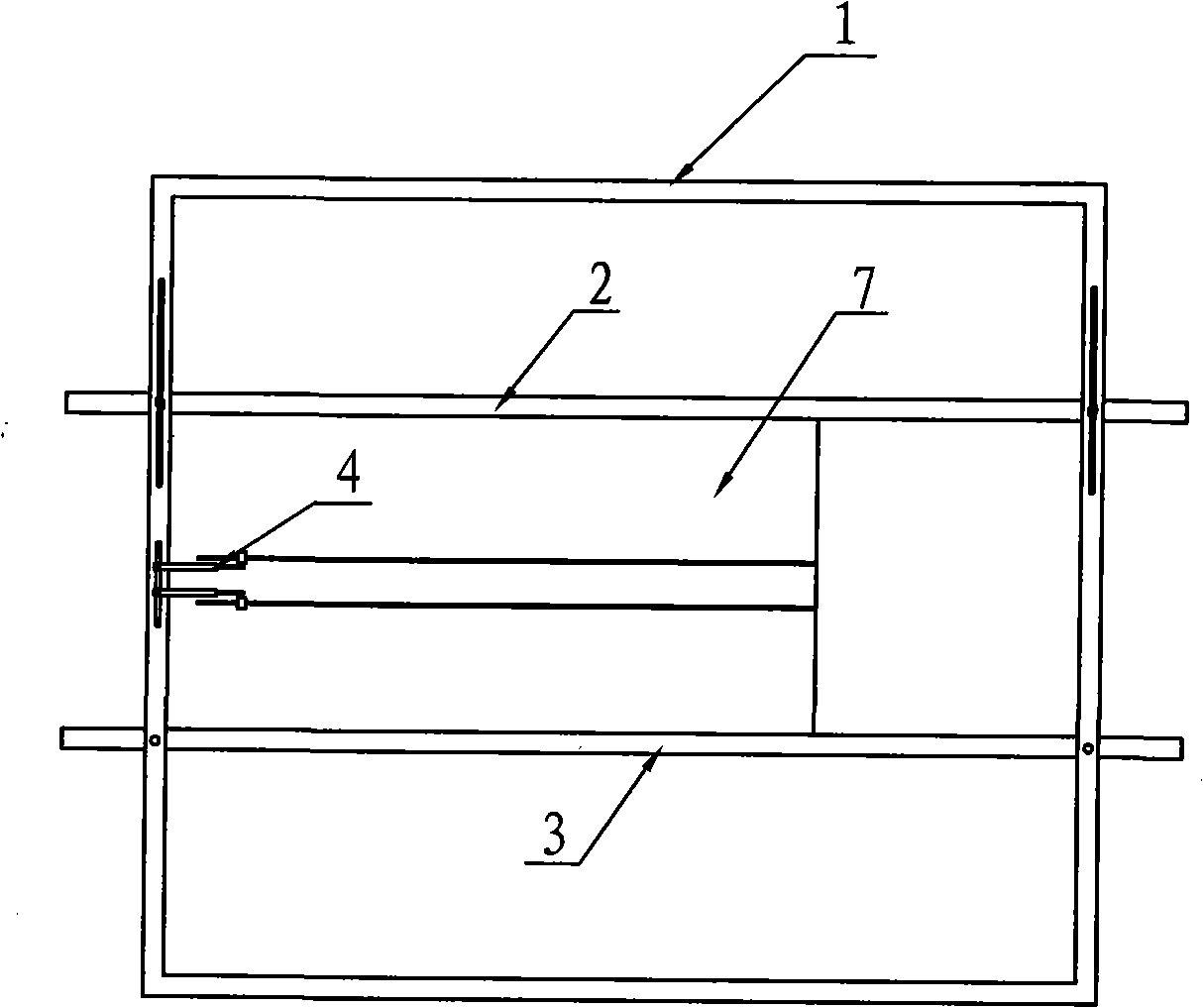

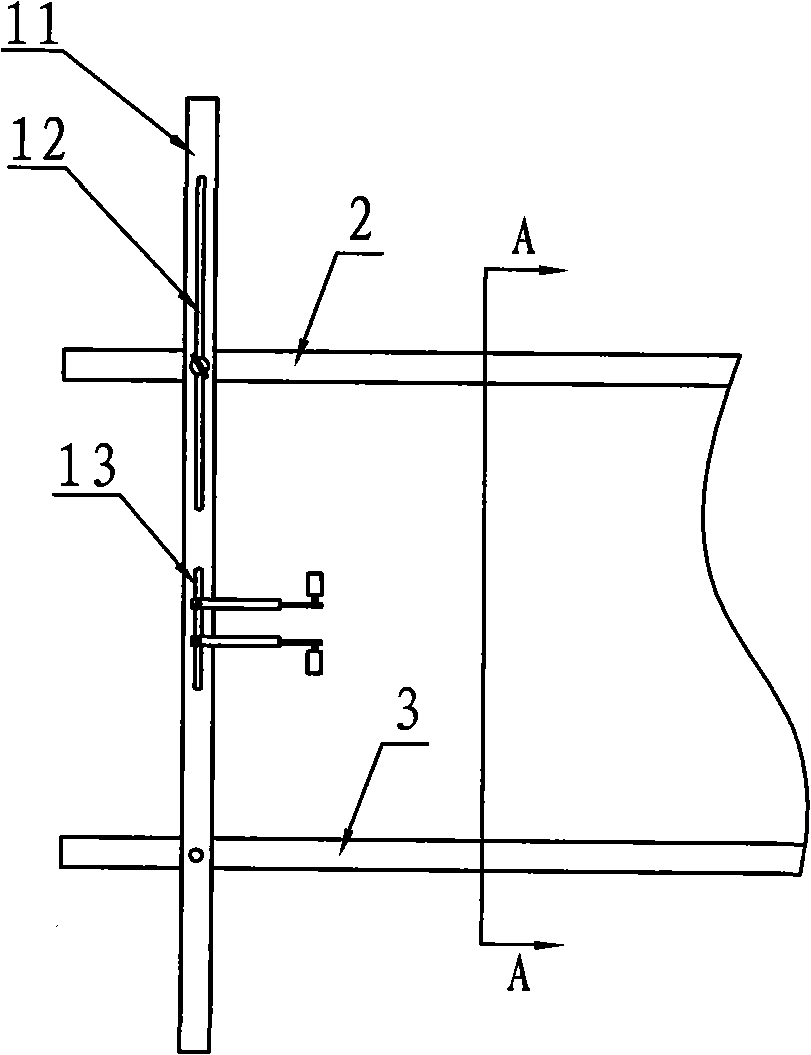

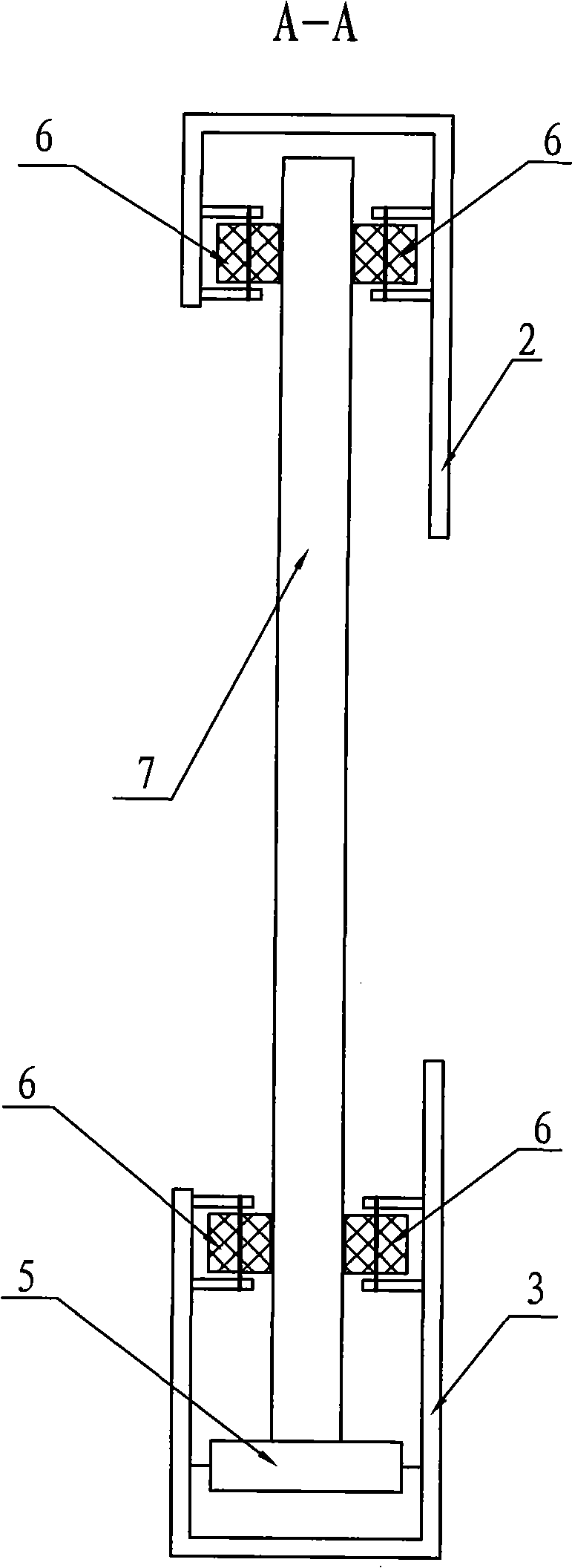

[0016] The special device for infrared thermal image testing of laminates according to the present invention, such as Figure 1~4 As shown, it includes a frame 1, an upper track 2, a lower track 3, a rolling contactor 4 and a bottom rolling rubber wheel 5. The frame 1 includes two vertical bars 11 arranged in parallel on the left and right, and the two vertical bars 11 The upper part of the upper section is provided with an upper rail adjustment groove 12, and an electrical connector adjustment groove 13 is arranged in the middle. In the upper rail adjustment groove 12 of the upper section of the straight rod 11, the cross-sectional shapes of the upper rail 2 and the lower rail 3 are both asymmetrical U-shaped, and the opening of the upper rail 2 is downward, the opening of the lower rail 3 is upward, and the bottom rolling rubber wheel 5 Set at the bottom of the lower track 3, the rolling contactor 4 is composed of a positive lead post 41 and a negative lead post 42, and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com