Condenser tube for improved condenser and processing technology of condenser tube

A condensing tube and condenser technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of poor stability, poor cooling effect of condenser, large space occupation, etc., achieve high stability and improve heat dissipation effect, the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

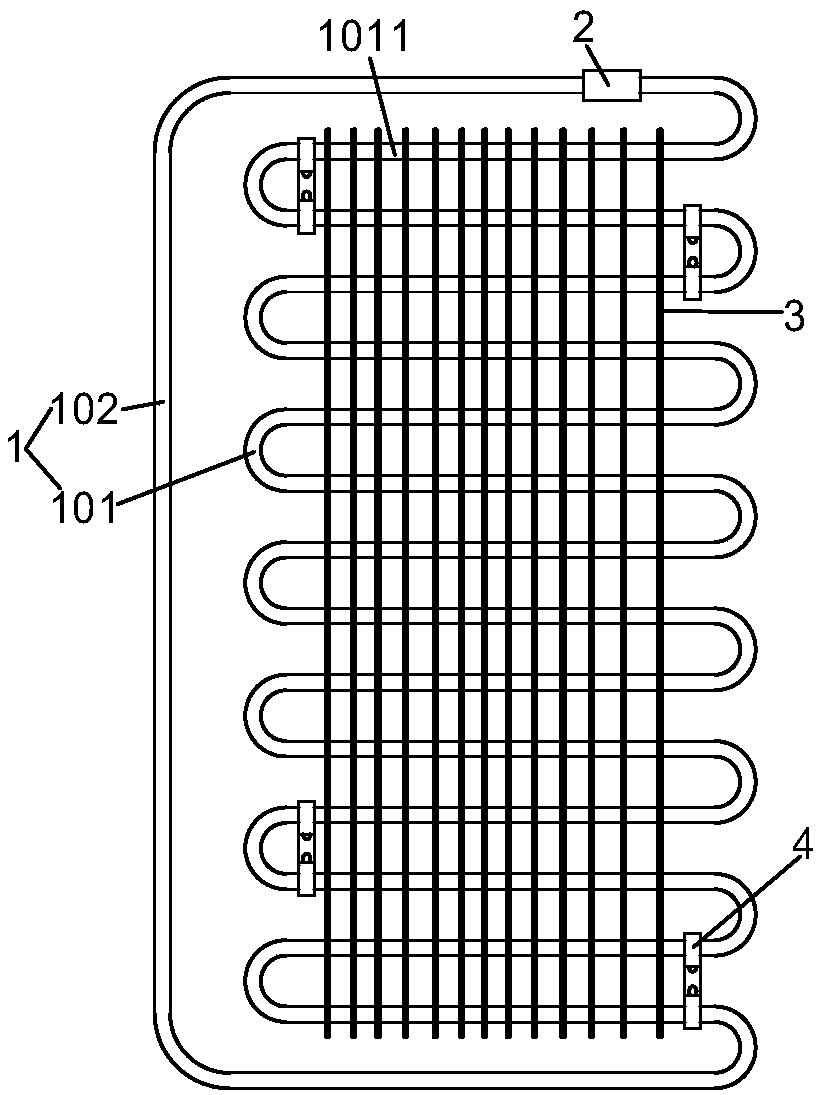

[0023] refer to figure 1 Shown: a condensing tube of an improved condenser, including a condensing tube main body and a reinforcement structure cooperating with the condensing tube main body, the condensing tube main body includes an "S"-shaped pipe section 101, and one end of the "S"-shaped pipe section 101 is connected with "U"-shaped pipe section 102, the "U"-shaped pipe section 102 is placed outside the "S"-shaped pipe section 101, and the other end of the "S"-shaped pipe section 101 and the unconnected end of the "U"-shaped pipe section 102 are detachable through the connecting joint 2 Connection; "S"-shaped pipe section 101 includes several straight pipe joints 1011 arranged at intervals, and the reinforcement structure includes several reinforcing steel wires 3 arranged at intervals on "S"-shaped pipe section 101 and arranged in a staggered manner on both sides of "S"-shaped pipe section 101 A number of reinforcement clamps 4, each reinforcement steel wire 3 is set acro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap