Train bearing fault diagnosis method based on multi-directional reconstruction

A fault diagnosis, multi-directional technology, used in mechanical bearing testing, motor vehicles, thermometer applications, etc., can solve problems such as missing reports of abnormal conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0066] The method of this embodiment is as follows:

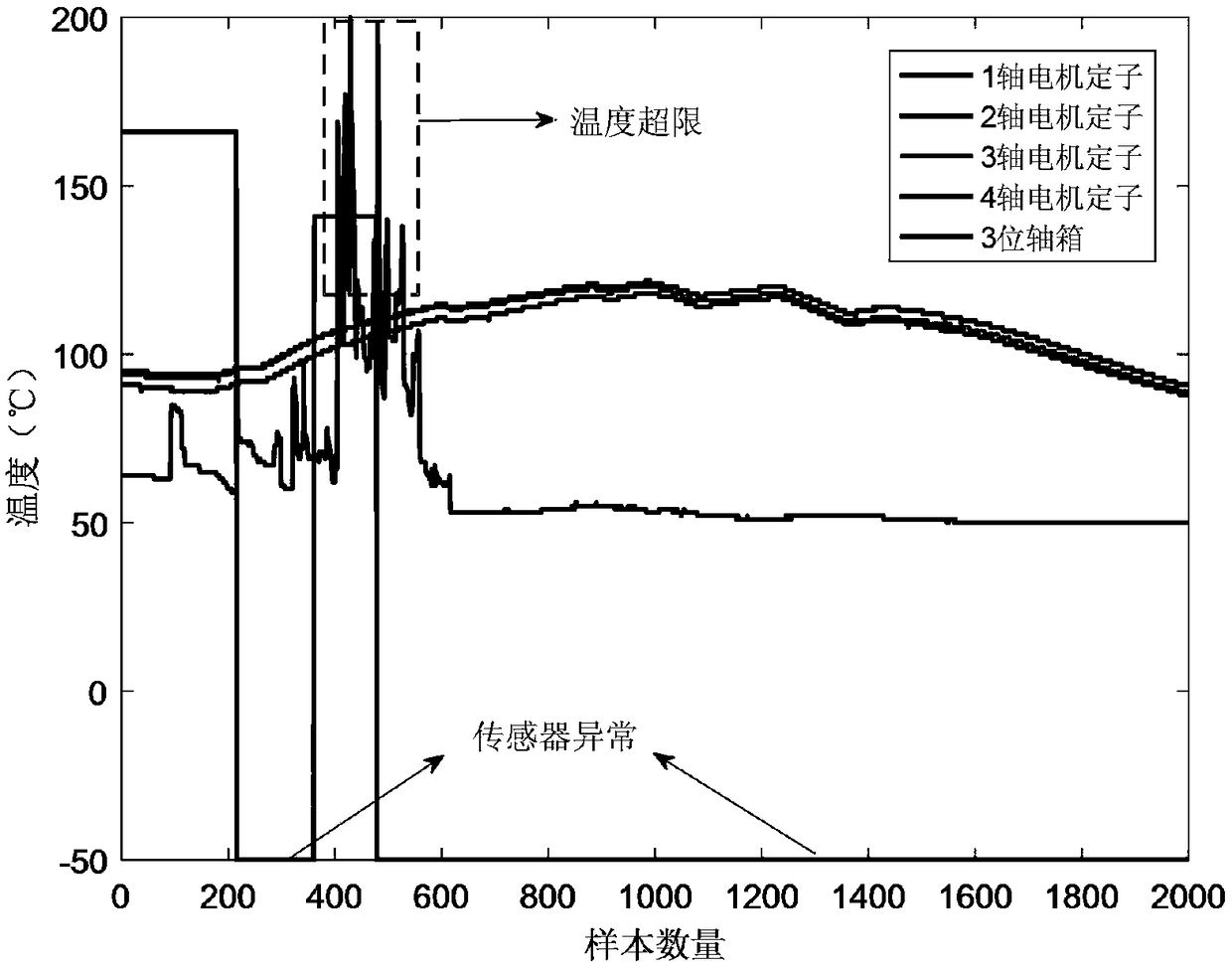

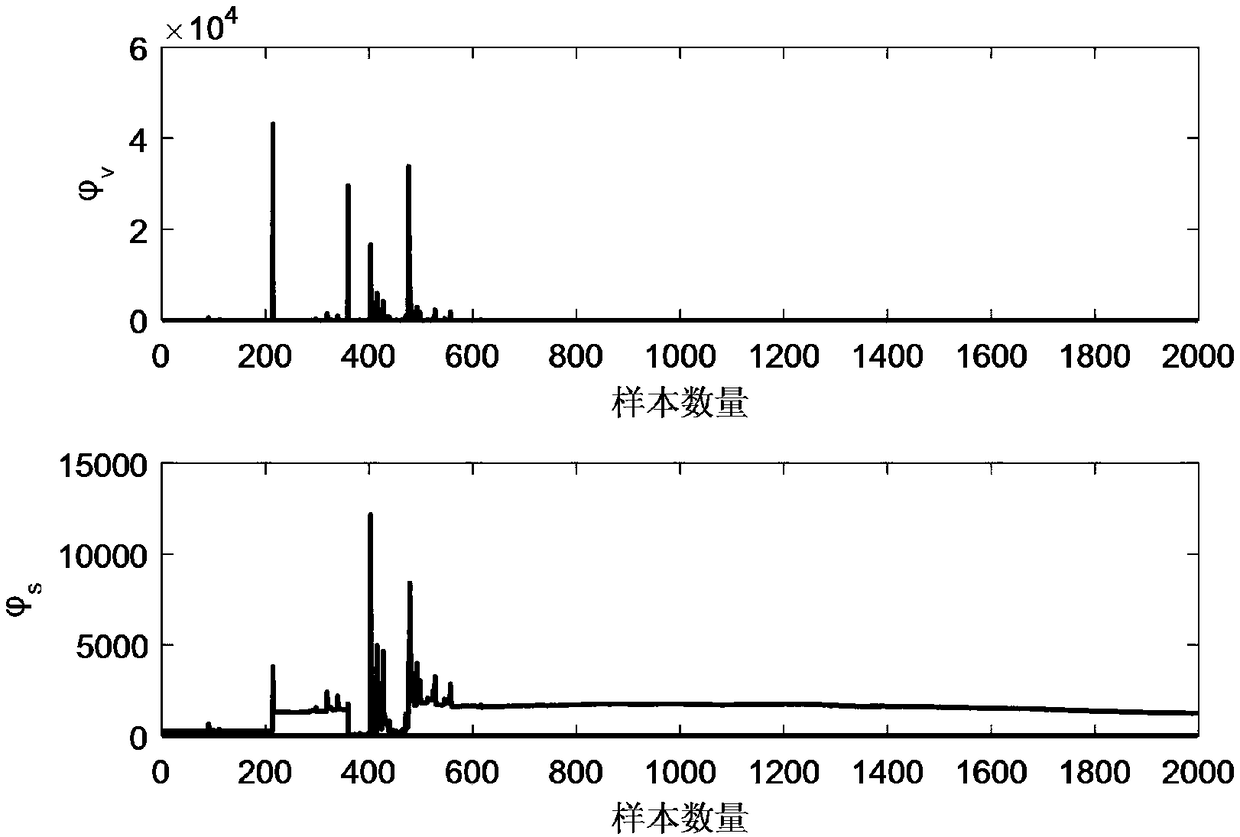

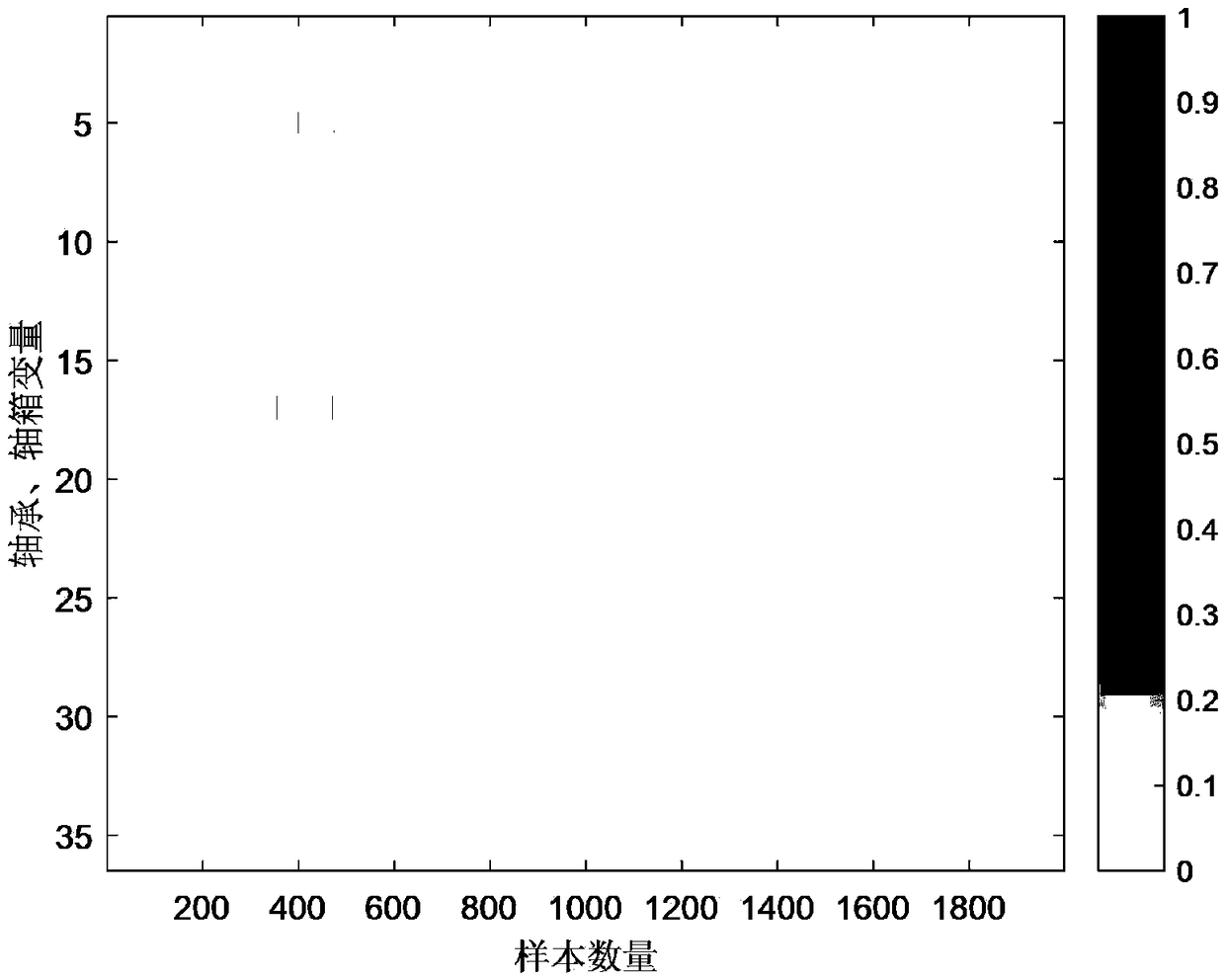

[0067] The embodiment of the invention is for fault bearing location during train operation. The 36 temperature sensors on the train correspond to 36 important positions, and the 36 temperature sensors are used to monitor the working status of the train bearings. It contains 4 bearings, each bearing has 7 temperature sensors (small gearbox motor side, small gearbox wheel side, large gearbox motor side, large gearbox wheel side, motor stator, motor drive end, motor non-drive end ). Also included are 8 axle boxes, each with a temperature sensor, for a total of 36 sensors. In the collected train bearing temperature dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com