Water quality monitoring method based on continuous flow membraneless biocathode microbial fuel cell

A fuel cell and water quality monitoring technology, applied in biochemical fuel cells, measuring devices, analytical materials, etc., can solve problems such as failure of early warning, weakening of output signal decline of toxic pollutants, etc., to prolong service life, reduce construction cost, The effect of maintaining pH balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

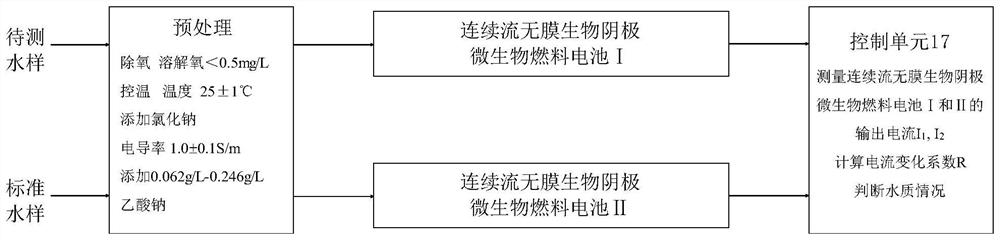

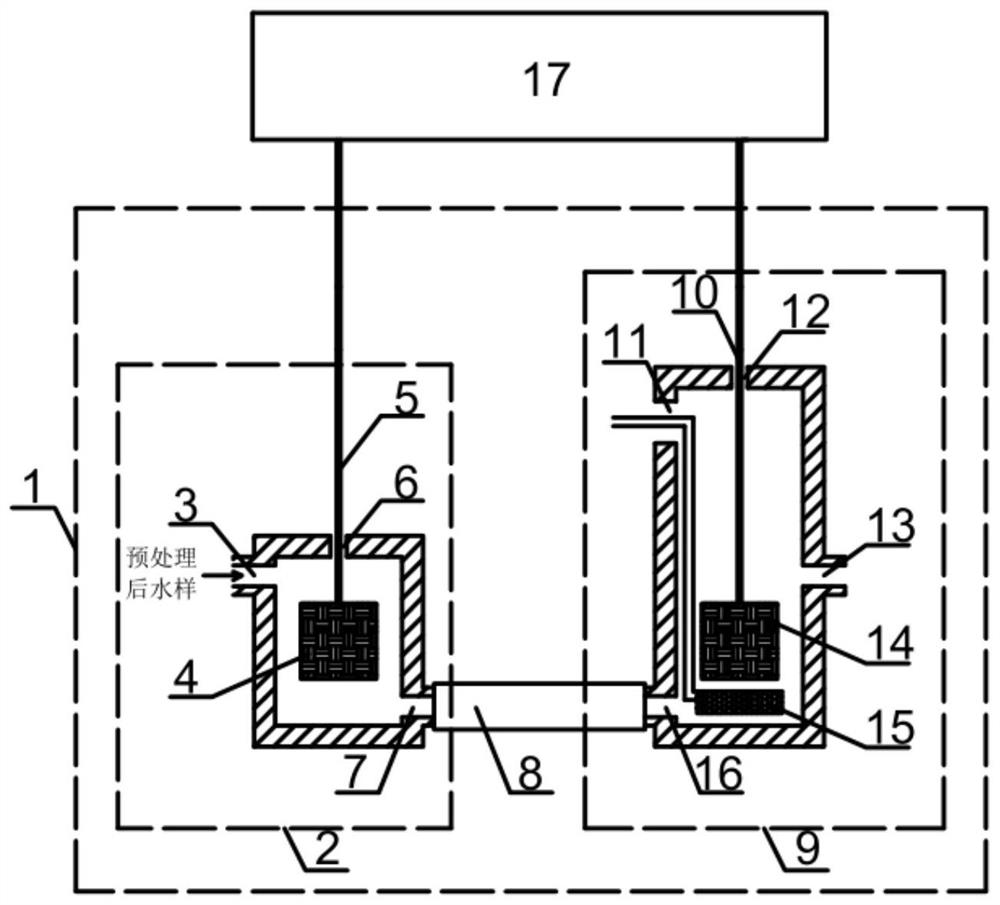

[0024] The composition of a specific continuous flow membraneless biocathode microbial fuel cell provided by the invention is as figure 2 As shown, the continuous flow membraneless biocathode microbial fuel cell 1 includes an anode detection unit 2 , a cathode detection unit 9 and a cathode-anode communication pipe 8 .

[0025] The shape of the anode detection unit 2 is a cuboid, and the inside is a cylindrical cavity with a diameter of 3 cm, a height of 4 cm, and a volume of 28 mL. An anode carbon cloth electrode 4 is placed inside the cavity, and the surface of the electrode is covered with electrochemically active microorganisms. For the anaerobic biofilm formed, the top of the anode detection unit 2 is provided with an anode electrode hole 6 , and the anode carbon cloth electrode 4 is led out through a titanium wire 5 and connected to the control unit 17 . The side wall of the anode detection unit 2 is respectively provided with an anode water inlet 3 and an anode water o...

Embodiment 2

[0031] In this example combine Figure 4 , indicating that the method provided by the invention is used to monitor the output current change of a single toxic pollution event.

[0032] The amount of sodium acetate added in the pretreatment step is 0.082g / L, and the water sample to be tested does not contain organic matter before treatment, so after pretreatment, sodium acetate is used as a single organic compound in the standard water sample and the water sample to be tested, and its concentration is 0.082g / L. Add heavy metal mercury to the water sample to be tested, so that Hg 2+ The final concentration is 1.5mg / L, simulating a single toxic pollution event. The water sample inlet flow rate was set at 2mL / min, and the detection time was 30min.

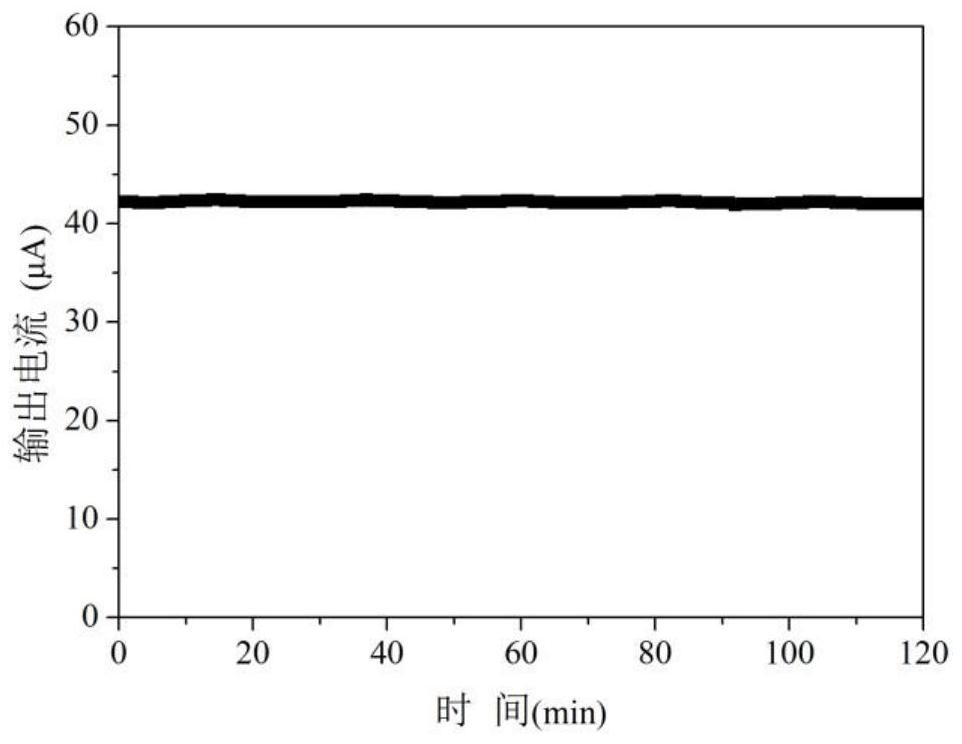

[0033] like Figure 4 As shown, during the detection process, the output current I of the continuous flow membraneless biocathode microbial fuel cell II fed with standard water 2 It is always stable at 45.2±0.1μA, while the output...

Embodiment 3

[0035] In this example combine Figure 5 , indicating that the method provided by the invention is used to monitor the output current change of the organic matter overload event.

[0036] The amount of sodium acetate added in the pretreatment step is 0.082g / L, and the water sample to be tested contains 0.082g / L sodium acetate before treatment, so after pretreatment, the sodium acetate concentrations in the standard water sample and the water sample to be tested are respectively 0.082g / L and 0.164g / L. The water sample inlet flow rate was set at 2mL / min, and the detection time was 30min. like Figure 5 As shown, the output current I of the microbial fuel cell I 1 After passing through the water sample to be tested, it will decrease significantly, while the output current I of the microbial fuel cell II 2 keep it steady. The value of the current change coefficient R varies with I 1 If it exceeds 20 after 18 minutes of passing through the water sample to be tested, it is jud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com