Light guide plate and preparation method thereof

A technology of light guide plate and fluorescent ink, applied in the field of light guide plate, can solve the problems of low adhesion, poor dot printing effect of light guide plate, affecting the light output effect of backlight module, etc., and achieve good light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

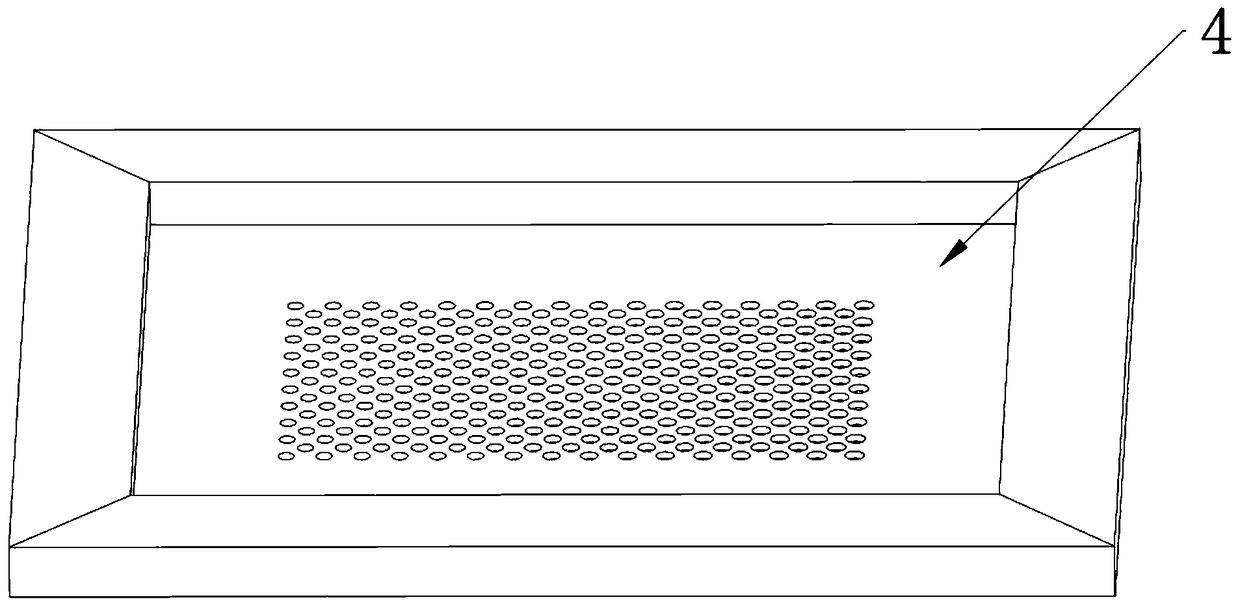

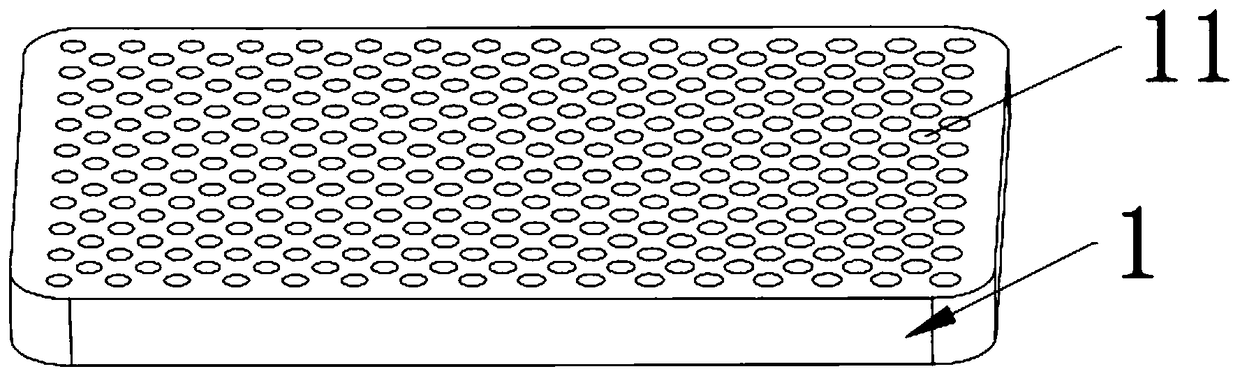

[0039] refer to Figure 1 to Figure 5 , figure 1 It is a schematic diagram of the structure of the light guide plate body when it is not etched, figure 2 is a schematic diagram of the screen structure, image 3 It is a schematic diagram of the structure of the light guide plate body after etching, Figure 4 It is a cross-sectional view of the light guide plate body after etching on one side, Figure 5 It is a cross-sectional view of the main body of the light guide plate after printing on one side. In this embodiment, the light guide plate includes a light guide plate body 1 and a plurality of first printing dots 2 printed on the light guide plate body 1 .

[0040] The light guide plate body 1 is a transparent plate made of PMMA material, that is, an acrylic plate; the light guide plate body 1 in this embodiment is a rectangular plate with a thickness of 6mm, and one side of the light guide plate body 1 is provided with a plurality of dislocation-arranged first One netwo...

Embodiment 2

[0048] refer to Figure 8 , Figure 8 It is one of the flowcharts of the preparation method of the light guide plate, and the preparation method of the light guide plate in this embodiment includes the following steps:

[0049] S1, making a screen 4, on which optical dots are formed; the optical dots are designed first, and then a stencil is made according to the design of the optical dots. In this embodiment, the optical dot design can be designed by GTOOLS LGP software. Specifically, the optical dot design is carried out according to the dislocation arrangement of the first dot slots 11 in Embodiment 1, and then the corresponding steel mesh is made through the screen making process Version.

[0050] S2, the screen plate 4 is placed on one side of the light guide plate body 1, and screen printing is performed with an organic solvent, so that one side of the light guide plate body 1 is etched to form a plurality of first dot grooves 11 recessed into the light guide plate bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com