LED flip chip and manufacturing method thereof

A technology of flip chip and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high manufacturing cost and cumbersome manufacturing process, and achieve the effects of simple manufacturing process, good light output effect, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

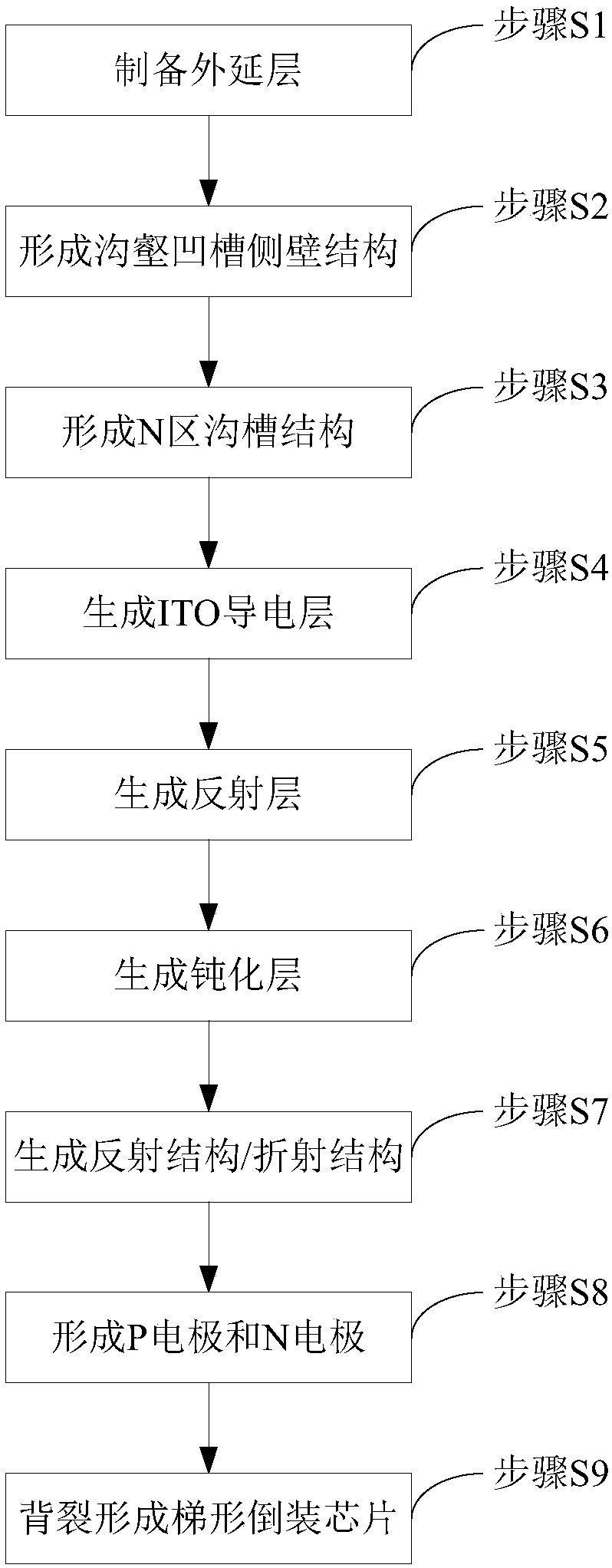

[0057] based on the following Figure 1 to Figure 10 , specifically explain the preferred embodiment of the present invention.

[0058] Such as figure 1 As shown, the present invention provides a LED flip chip manufacturing method, comprising the following steps:

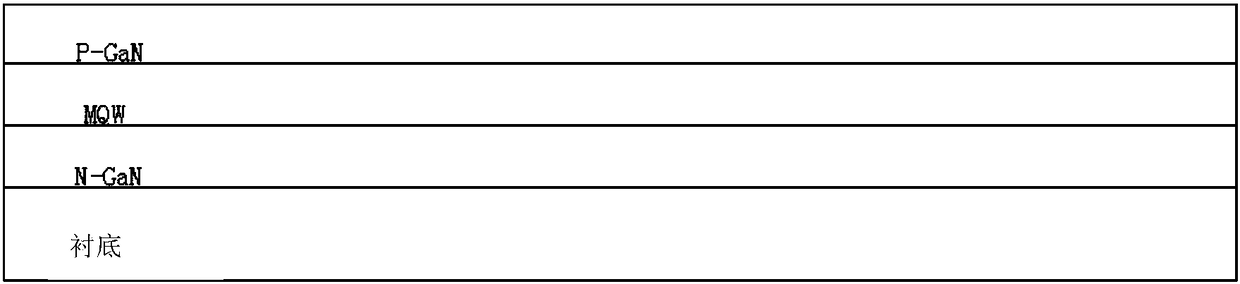

[0059] Step S1, preparing an epitaxial layer;

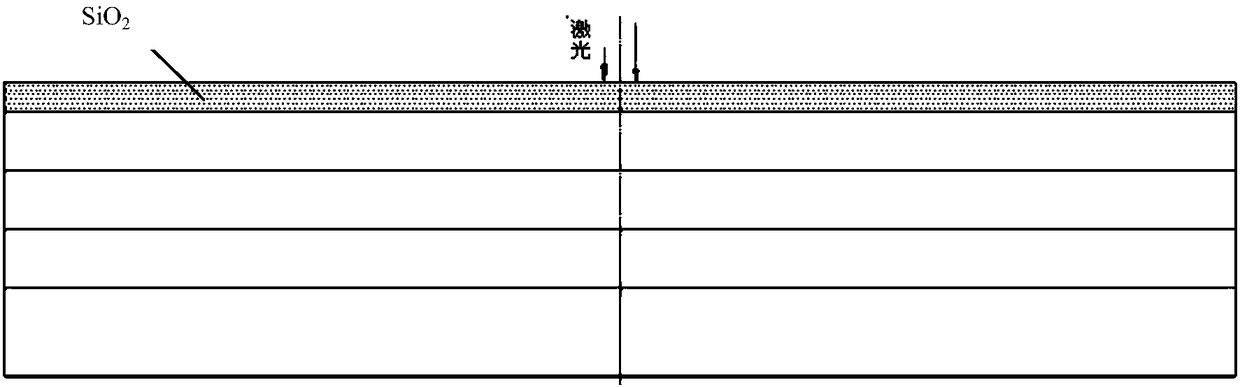

[0060] Step S2, using laser scribing and chemical sidewall etching to form the sidewall structure of the ravine groove;

[0061] Step S3, forming an N-region trench structure by etching between adjacent trench groove sidewall structures, the N-region trench structure is used as the N-region, and the epitaxial layers on both sides of the N-region trench structure are used as the P-region;

[0062] Step S4, generating an ITO conductive layer on the epitaxial layer in the P region;

[0063] Step S5, generating a reflective layer (Ref) on the ITO conductive layer in the P region;

[0064] Step S6, forming a passivation layer on the reflective layer in the P region, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com