Optics and manufacturing method of led car high beam combination lamp

A technology of LED light source and combination lamp, which is applied in the direction of semiconductor devices, light sources, electric light sources, etc. of light-emitting elements, can solve the problems of complex structure and cost a lot of money, and achieve the effects of good light efficiency, saving manufacturing costs, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

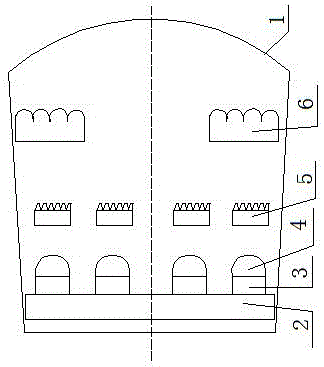

[0023] An LED car high beam combination lamp, which comprises: a high beam combination lamp housing 1, an aluminum-based PCB board 2 is housed in the high-beam combination lamp housing, and the aluminum-based PCB board is connected to a white LED light source group 3. The white LED light source group is connected to the infrared LED light source group 4, a Fresnel lens group 5 is installed in front of the infrared LED light source group, and a fly-eye lens group 6 is installed in front of the Fresnel lens group.

[0024] In the LED car high beam combination lamp, the white LED light source in the white LED light source group has a light emitting angle of 30-80 degrees, and the infrared LED light source in the infrared LED light source group has a light emission angle of 30-80 degrees Angle, the diffusion angle of the fly-eye lens in the fly-eye lens group is ±45 degrees.

Embodiment 2

[0026] An optical method for an LED car high beam combination lamp, the white LED light source group and the infrared LED light source group are arranged on a square dot matrix aluminum-based PCB board, and the aluminum-based PCB board is placed at the focal position of the Fresnel lens group, The light emitted by the LED in the middle position passes through the corresponding Fresnel lens array in front of it to generate a collimated beam to form the light distribution of the high beam of the car. The surrounding white LED light source groups and infrared LED light source groups are arranged alternately. The lens group forms a collimated light beam, and then forms the light distribution of the car daytime running lights and the auxiliary light distribution of infrared night vision through the fly eye lens group.

Embodiment 3

[0028] A manufacturing method of LED automobile high-beam combination lights, welding or bonding white LED light source groups and infrared LED light source groups on an aluminum-based PCB to form a light source lattice, and clamping a Fresnel lens group on the light source as the focal point Install the fly-eye lens group in the coaxial position where daytime running lights and night vision auxiliary light distribution are required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com