A fault detection method based on automatic encoder and Bayesian network

A technology of Bayesian network and autoencoder, which is applied in the direction of instruments, character and pattern recognition, manufacturing computing systems, etc. It can solve problems such as dynamic time expansion without consideration, and achieve the effect of satisfying diagnosis, rapid diagnosis and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

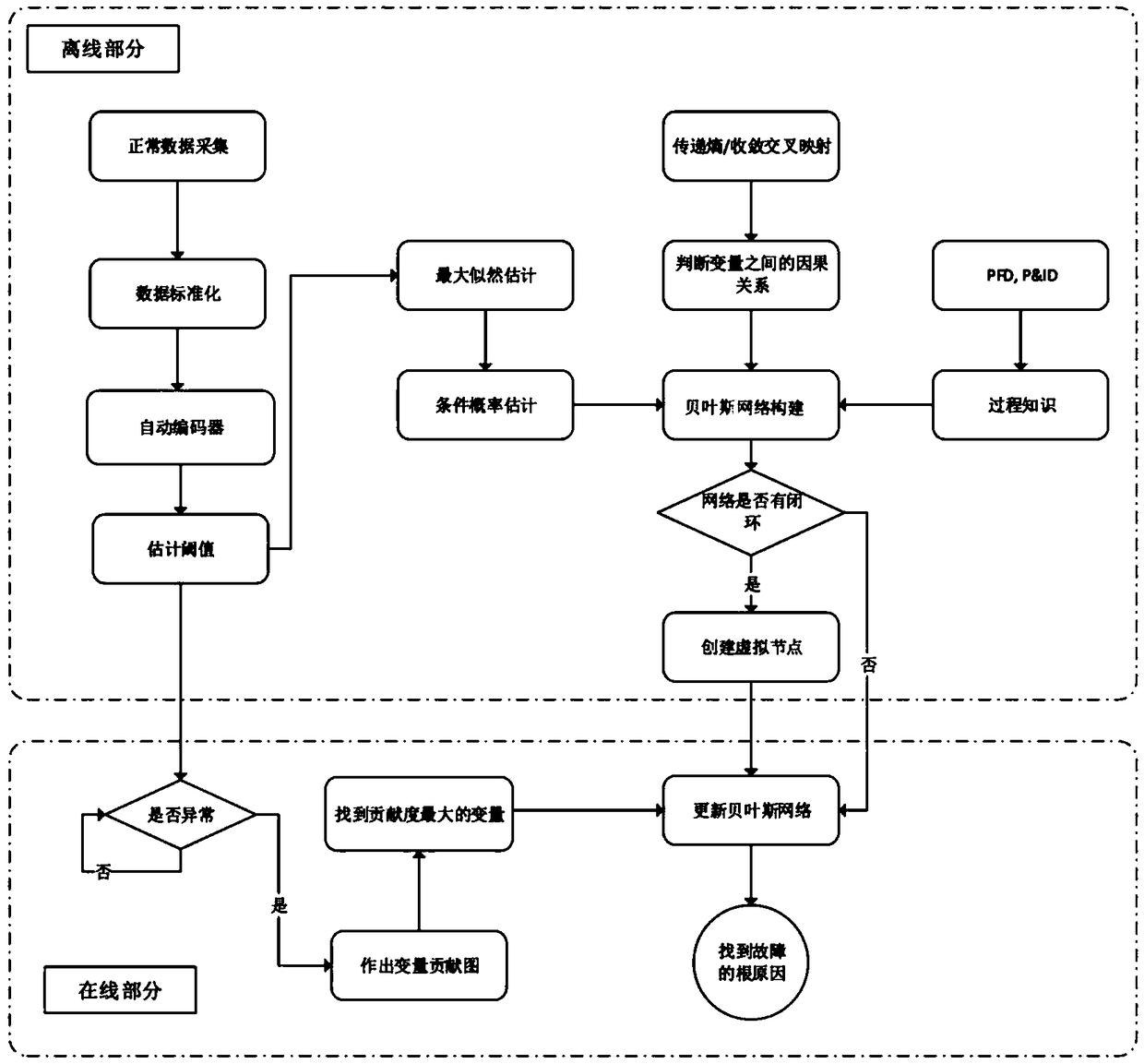

[0060] The present invention proposes a fault detection method based on an autoencoder and a Bayesian network, which will be further described in detail below in conjunction with the accompanying drawings and specific implementation examples.

[0061] The present invention proposes a fault detection method based on an autoencoder and a Bayesian network, which is divided into an offline stage and an online stage. The overall process is as follows figure 1 shown, including the following steps:

[0062] 1) Offline stage;

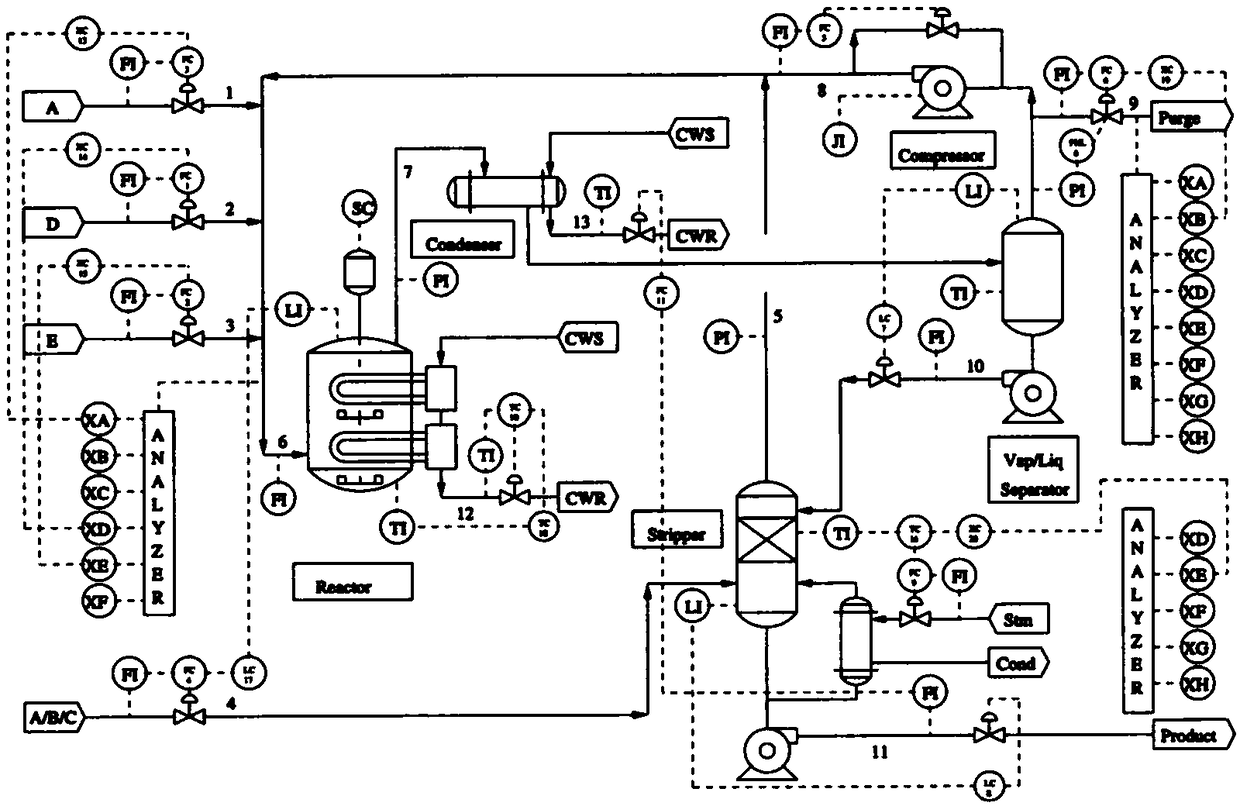

[0063] 1-1) Collect the data of the chemical production process and build a sample data set;

[0064] Select several variable data from any continuous chemical production process to construct a chemical process data set. The selection of variables is selected according to the specific chemical process; select one of the appropriate lengths from the chemical process data set (the general length is 10 of the number of selected variables) to 50 times) of normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com