Battery module and manufacturing method thereof

A technology of battery module and manufacturing method, which is applied in secondary battery manufacturing, batteries, secondary batteries, etc., can solve problems such as bolt deformation, and achieve the effects of reducing weight, alleviating stress concentration, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

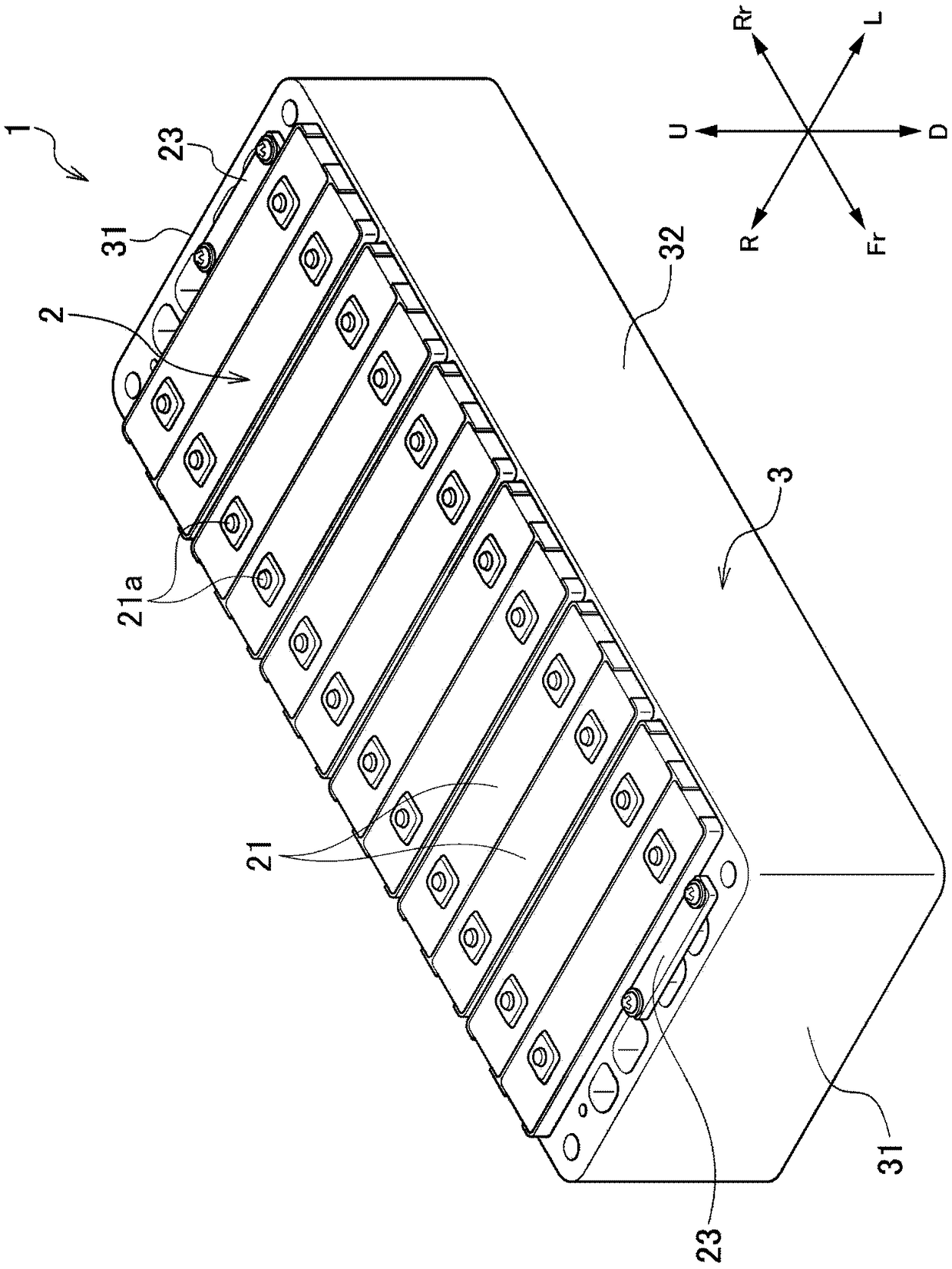

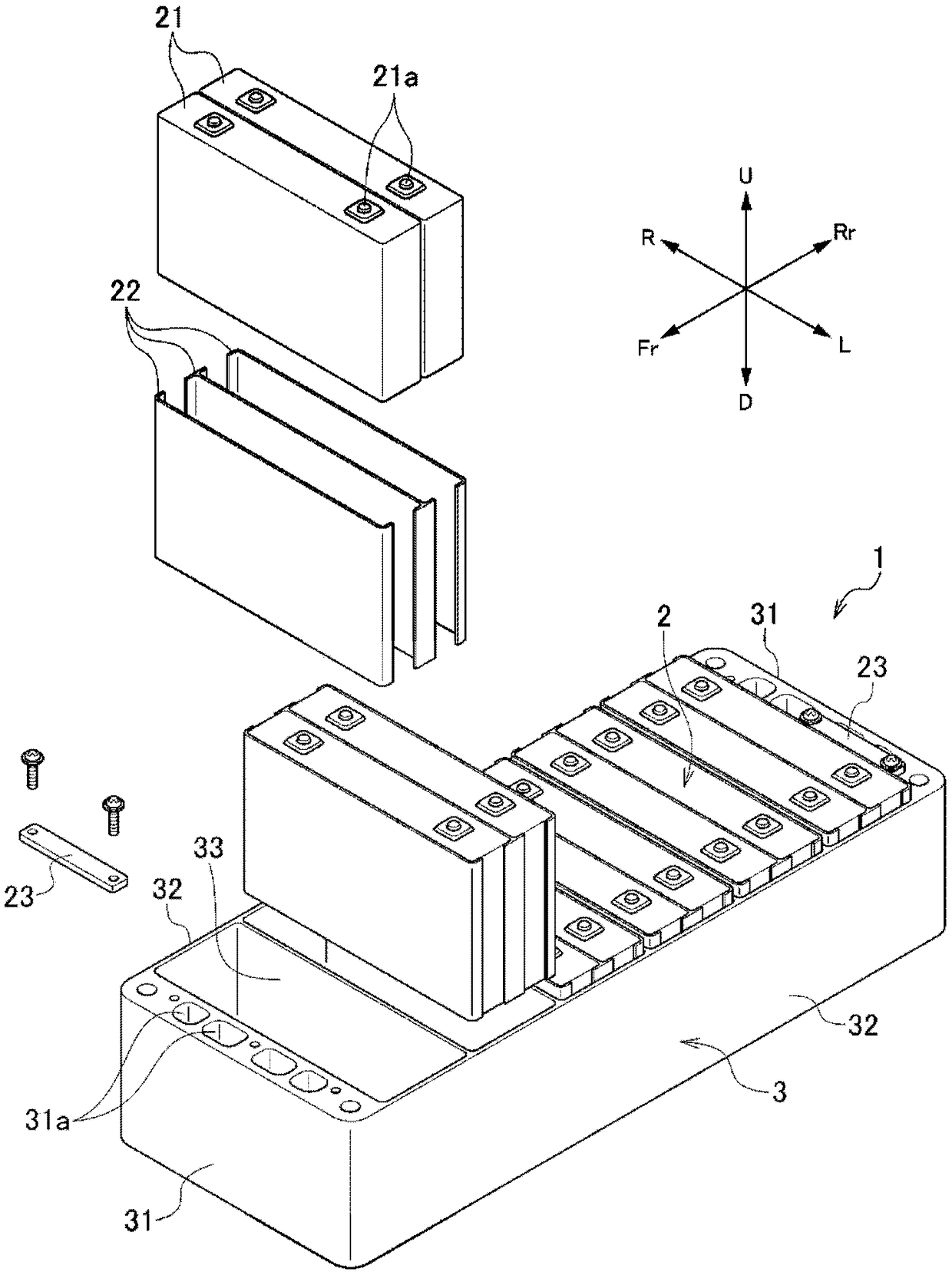

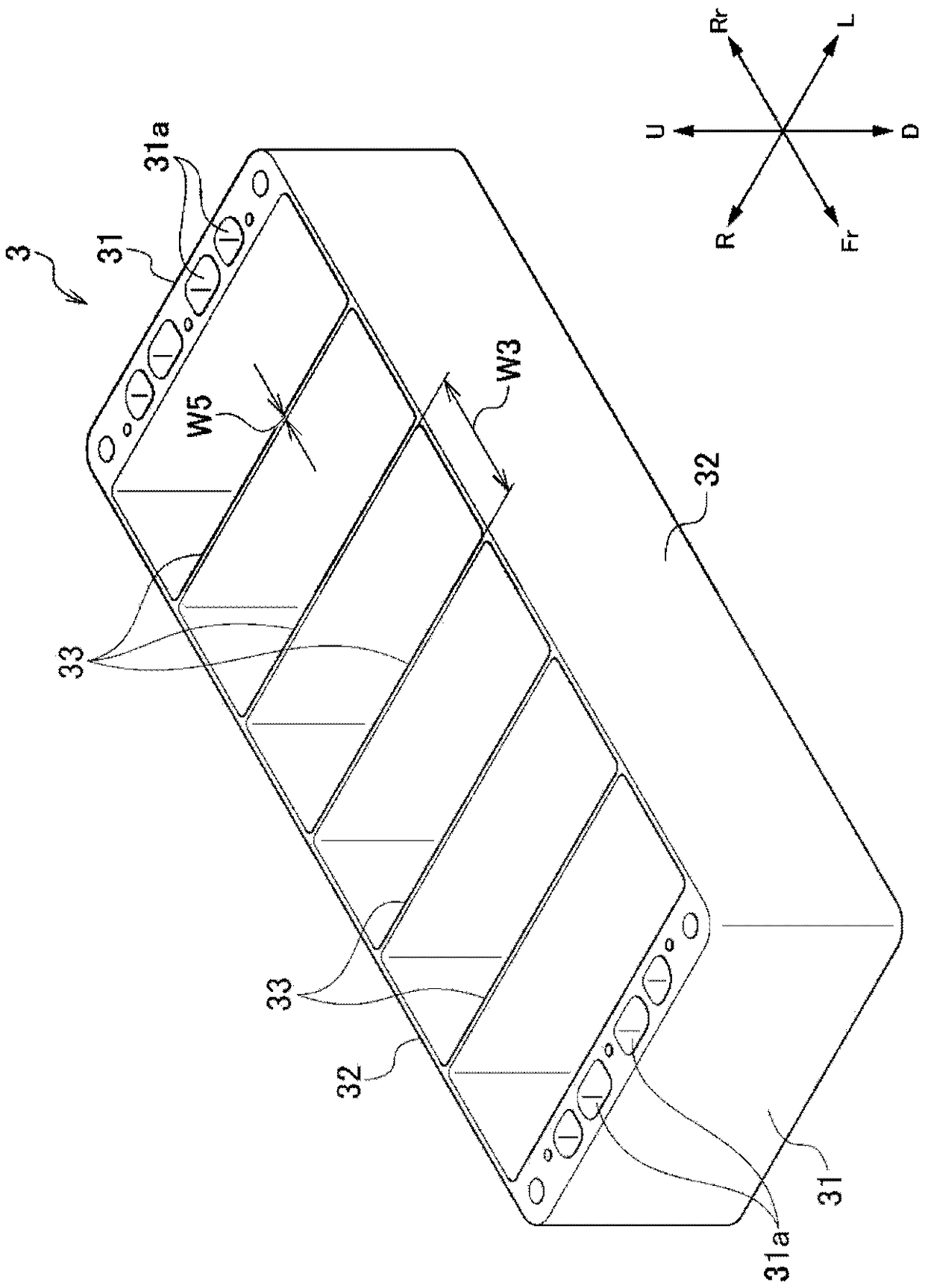

[0083] Such as Figure 1 to Figure 4 As shown, the battery module 1 according to the first embodiment of the present invention includes a single cell stack 2, which is formed by stacking a plurality of single cells 21 in the front-rear direction, and has a front surface, a rear surface, a left surface, a right surface, an upper surface, and a lower surface; and a case 3 that accommodates the cell stack 2 .

[0084] It should be noted that, in this specification and the like, for the sake of simplicity and clarity of description, the stacking direction of the cells 21 is defined as the front-rear direction, and the direction perpendicular to the stacking direction of the cells 21 is defined as the left-right direction and the up-down direction, The front-back direction of the product on which the battery module 1 is mounted is not relevant. That is, when the battery module 1 is mounted on a vehicle, the stacking direction of the cells 21 may coincide with the front-rear direct...

no. 2 approach

[0107] Next, refer to Figure 5 and Image 6 A battery module according to a second embodiment of the present invention will now be described. However, only the points of difference from the first embodiment will be described, and the description of the first embodiment will be referred to by using the same reference numerals as those of the first embodiment for the configurations common to the first embodiment.

[0108] Such as Figure 5As shown, the battery module 1B according to the second embodiment differs from the first embodiment in that a bridge portion connecting the pair of side portions 32B to each other is not formed in the case 3B. It should be noted that, in Figure 5 In , the cell stack 2 is omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com