10KV step-down starting cabinet

A high-voltage start-up and action part technology, applied in the field of mining equipment, can solve problems such as hindering production, operators and high-voltage equipment line safety operation hazards, and achieve the effects of convenient maintenance, low noise and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

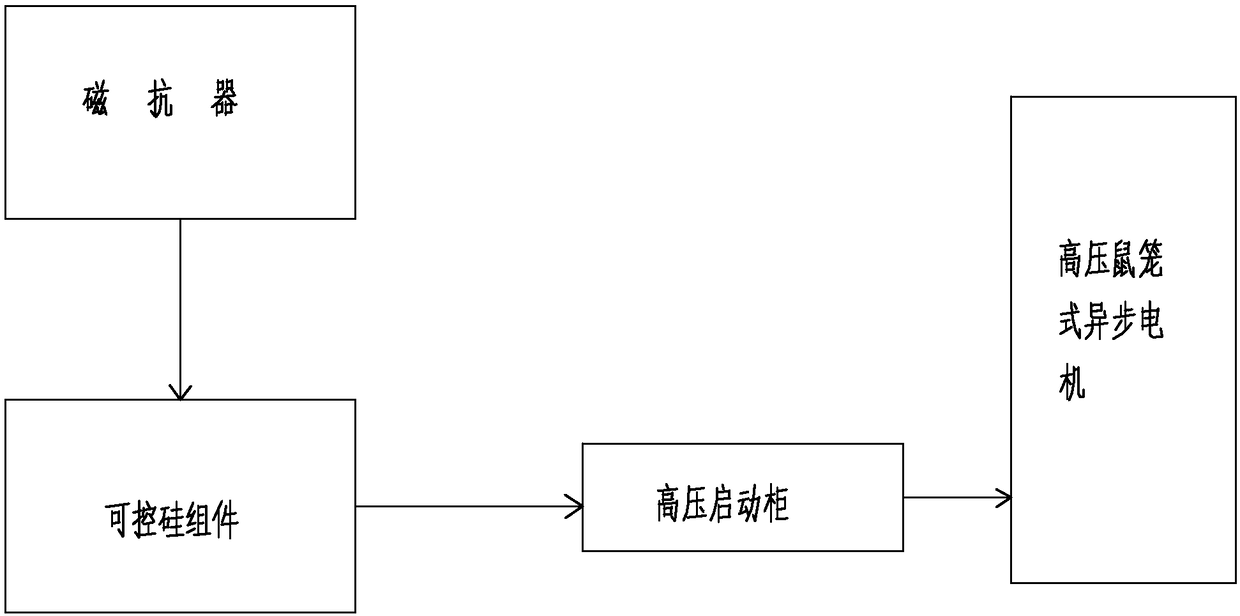

[0011] Such as figure 1 The 10KV step-down starter cabinet shown is characterized in that it includes a control part and an action part. The control part is used to drive the action part. The control part includes a magnetic reactor and a thyristor component, and the magnetic reactor is connected to the thyristor Components, SCR components are used to drive the action part.

[0012] The said action part includes a high-voltage starting cabinet and an asynchronous motor, the thyristor component controls the high-voltage starting cabinet, and the high-voltage starting cabinet controls the asynchronous motor.

[0013] The asynchronous motor is a high-voltage squirrel-cage asynchronous motor.

[0014] The magnetic reactor plus the SCR components form a closed structure outside the cabinet to adjust the magnetic field gap to control the starting current. During the starting process, only the control circuit breaker is closed. After a delay, the bypass circuit breaker is turned on to achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com